Tebis Presents the new version 3.5 in the BIEMH

18 May 2010

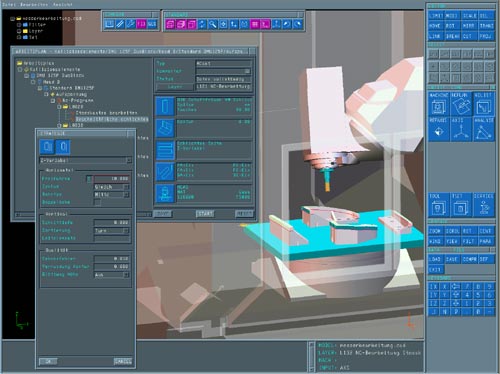

A prerequisite for productive work are the structures tested and demonstrated in practice. That is why some years ago Tebis began to offer their customers new possibilities to create structures of manufacturing within the system. The new version of Tebis 3.5 offers even more possibilities of storing these structures.

The new technique of the work plan, for example, plays the course of manufacture, and in advance guarantees a great overview and a forecast of the machining. Act followed, all the information of manufacturing are created centrally, which again increases the transparency and therefore permanently stored knowledge of manufacturing processes.

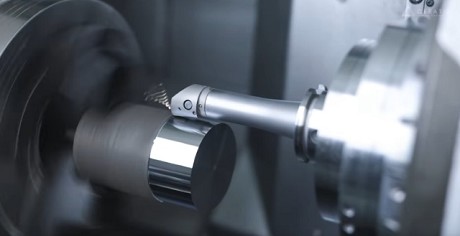

The integrated machines library structure and view the individual machines Park of each client. This allows to have a good overview of the situation of real machining which will be given later. The collision and controls end of career can be made already before the NC programming also contribute to this.

Improved tools library supports the reproduction of technology parameters tested in the CAD/CAM system in even more detail. In this way you can adapt the technological data associated with each tool and material to be machined in optimum and individual way. This prevents occurring incorrect values of court at the time of milling already from the beginning. Repetitive machining tasks can automate and standardize even more accurately.

The formal labour is a prior and important condition for automatic NC processes. Another condition is the intelligent application of these templates. And here also the V3.5 version has something to offer:

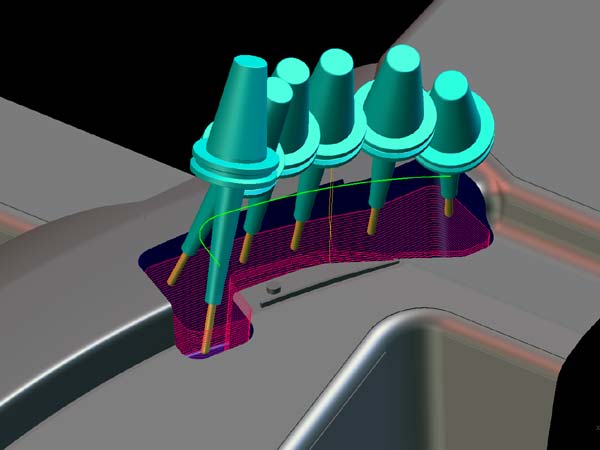

NC templates ranges (NC-jobs) automatically selects the elements of collision from structures and according to criteria of own CAD geometry and machining machining. For parts that are manufactured with similar machining sequences, this gives rise to a fully automatic NC programming. Working with proven and tested methods becomes even easier.

Another point is variable NC templates (NC-sets) with what defined sequences of machining automatically seek the right tool depending on the geometry of piece.

The example that we have tabled before represents only some of the innovations that improve still further the work structured with Tebis. But the new Tebis version also incorporates advances in the functional area. Here it is worth mentioning the new strategies of excess material, or extensions in 5-axis milling and processing of data of digitalization. In short, the new version 3.5 of Tebis provides more automation, more control over the processes, smarter and faster in all CAD/CAM tasks.