Röhm presents their newest mooring systems in the BIEMH

May 17, 2010

Röhm Iberian exhibits in the machine-tool biennial, Bilbao (Hall 3, stand G43) their main developments in mooring: segmented tweezers Absis and Agilis, the Röhm clocked and KKHFR dishes.

In front of the systems of tie up inner more traditional, the systems Absis and Agilis, do not base his capacity of tie up in the capacity of deformation of pinzas metallic of an alone traditional piece. The solution posed by these new systems revolutionises previous concepts splitting of a pinza compound of different segments indeformables, joined by elements of deformation controlled. The employment of the solutions Absis and Agilis, guarantees some levels of upper precision to the traditional systems, with the advantage added of an useful life of the pinzas cementadas very upper to other alternatives, likewise the concept of pinzas segmentadas, allows the employment of new materials for the tie up by mandriles, what is supposing a net improvement in every aspect. The pinzas segmentadas Absis and Agilis, can be manufactured with diverse profiles, in function of the piece to tie up (tie up of piñones with toothed interior, etc.).

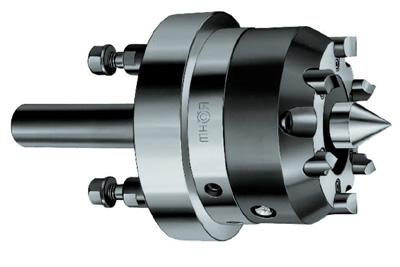

For its part, the Röhm clocked are a tool very versatile mooring for the most diverse applications, thanks to its great flexibility in mooring and its excellent performance of high-precision ranges. These devices perform its mooring by friction on the face front of the piece for turning, grinding and various applications. Röhm has had successful experiences with the use of their clocked in as delicate as temperate integral operations by induction of crankshafts. The Röhm clocked are used by the factories highlights, getting fully satisfactory results in the most demanding conditions, without that so they stop being less suitable for small and medium-sized businesses thanks to their extraordinary relationship quality price.

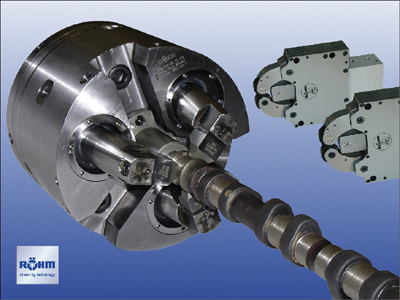

Röhm KKHFR dishes bring together all the virtues of the dishes together with the clocked Röhm, in one device offering the capability of turning raw, turning fine and even grinding of parts in a single mooring. These devices perform its mooring by combining a system of floating/pop-up claws with feedback and a drive system with compensation of roll, thanks to this excellent combination of moorings. These dishes are especially suitable for manufacture of type 'axis' pieces requiring high degrees of accuracy and speed of production.