Generic Motion Control: a new trend in automation

May 14, 2010

The world of CNC and robotics, tends more and more to create machinery with advanced and customized for each client functions. For this reason is already beginning to dispense with controls dedicated exclusively to CNC functions, taking advantage that Automation teams have greater flexibility to assume functions of motion control, CNC and robotics.

Standard CNC package

The GMC components form the core of many applications in a large number of different sectors. Especially in the machine tool sector there are a number of standard functions that can be found on any machine.

In this area is where B & R has taken a step forward in the standard software modules. In particular, the development of a package of standard CNC considerably reduces set-up time for customized solutions of machine tool.

The standard CNC package includes both the hardware and software functions necessary to operate a typical CNC machine.

Standard software package

The software includes all the important basics for operation, configuration and diagnosis of the entire system, in particular of all axes and CNC channels.

The display is based on Visual Components, which is the display integrated in real time of B & R system. In this way the user can directly access variables and functions that use the software. The standard display includes the basic components, the parameters of configuration and operation of the programmes, simulation tools, the diagnosis of the processes and the different graphics. Also the interface is designed so that the display can be extended with customer-specific functions.

Hardware - CNC panel

A panel of 15 "in a vertical format is used as display hardware. Based on the Power Panel 400, this panel integrated control and display on a single computer, with some integrated elements of operation:

- Programmable function and navigation display and control keys.

- A wheel for browsing through pages of the display elements.

- Six keys of pre-selection for quick access to the main pages.

- Two configurable keys for pages extras designed by the client.

- Boot and program Pause buttons.

- Ten bright pushbuttons for quick access to functions of machine operation.

- Selector to change the mode of work.

- Selector key for block specific functions.

- USB connector to Exchange files.

- RFID transponder for identification of the user.

- QWERTY keyboard.

Hardware - send mobile

CNC panel is complemented with a remote control in hand, allowing the operator of the machine to be able to move freely around the machine and hand movements from the most suitable position.

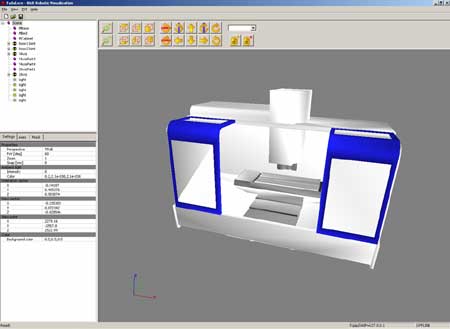

AR000 - simulation environment

Process simulation is playing an increasingly important role in the development of new machines. In the generation of motion profiles to CNC and Robotics is especially important that slogan values coincide with great precision in calculating trajectories that performs the real time system.

This is the only way to assess a trajectory generated in a simulation system and detect collisions or violations of the workspace before testing it in machine.

AR000 simulation environment is a platform of B & R based on the PC for the simulation of the functions of the GMC and all applications that are managed in a real-time system. In addition, the AR000 offers the possibility to climb the virtual cycle time respect of real-time. This means that the user can test processes faster or slower than the system in real time by a factor of scaling with respect to the real cycle time.

All the functions of the GMC are available at AR000. This allows to represent the entire system in an environment of simulation and without limitations. In addition the AR000 also includes the possibilities of the ACOPOS operating system. This way, basic movements, synchronization functions, electronic camshaft and internal blocks of the servo also can be simulated.