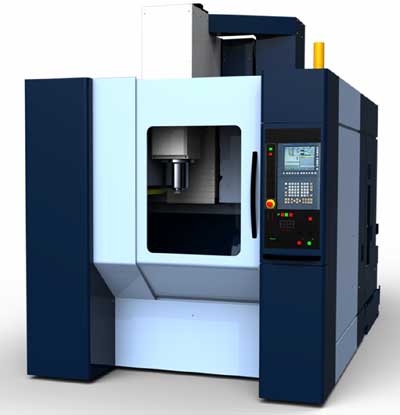

Maquinser presents the Matsuura MX-520 machining center

In 1991, Matsuura developed the MAM72 series designed for the production of high added value in 5-axis simultaneous machining, leading to multiple flexible configurations, various types of production and extensive capabilities in needy production. The 72 MAM has been a pioneer in simultaneous 5-axis machining centres. Since then the firm has sold numerous machines of this series around the world. The MAM72 demonstrated at the international level an excellent experience in various industrial fields in high demand in accuracy and reliability, such as automotive, aerospace and medical, with more than 1,000 machines sold around the world.

New vertical machining center 5-axes, MX-520.

The current economic situation demands more and more pieces of higher value-added, more complex and a rationalization of costs. The 520 MX offers as the optimal solution to users in need of 5 axes production unitary or short series machines. The 520 MX keeps the '5 - axes know-how' so much prestige given to Matsuura machines and achieved through the development and success of the MAM72 series.

The machine also has various support functions, necessary for new entrants, which guarantee safe machining (checking anti-colisiones system) and ease of use and programming, reducing the complexity of the passage of 3 to 5 axes machining to maximize, in its standard staffing.

The MX-520 in its compact construction ensures high rigidity, as well as a good capacity of machining. The MX-520 can contain pieces with sizes of up D520 mm and H350 mm, and its good accessibility, with the center of the table of 385 mm away from the door of the machine ensures easy access to the Workbench. A system for avoiding collisions only ' IPS: intelligent protection system ' is used in MX-520 to facilitate more complex 5-axis machining operations. In addition to IPS, the next generation operating system from ' MIMS: Matsuura Intelligent Meister System' is offered as standard. MIMS was developed to help the user to perform tasks of implementation (setup), operation and maintenance of machines, saving energy and labour, at the same time.

Matsuura will present the MX-520 in IMTS2010 is held in Chicago in September and also JIMTOF2010 to be held in Tokyo in late October.

MX-520 features

1 Operation

1.1 Distance from the ground up to the top surface of table: 850 mm

1.2. Distance from the door of the machine to the center of the table: 385 mm

1.3 Door width: 805 mm (enough for workpiece maximum D520 mm)

1.4 door with upper opening for loading of piece with crane

1.5 Size of the table: D300 mm (D500 mm: optional)

1.6 6 ports for the erection of the hydraulic system (optional)

2 IPS (intelligent protection system): standard

2.1 Unemployed in advance before a collision between the machine, tool, piece and accessory

2.2 Function anti-collision during manual operation or the implementation that may occur due to human error

2.3 Prevention of collisions during automatic operation that may occur due to programming error

3. New operating system MIMS (intelligent Matsuura Meister System): standard

3.1 Operation support functions

3.2. Four key words

(1) Reliability Meister [safety] to reduce the time of stoppage of machines

(2) operational Meister [User Friendly] ease of operation

(3) Thermal Meister [precision] thermal displacement compensation *

* The MX-520 is equipped with the axis of thermal displacement compensation

(4) Eco Meister [environment] to reduce standby energy