Broad participation of the represented by Siaisa in the Emo

September 15, 2009

Siaisa (society for research and applications Industriales, S.A.) It is a company founded in 1944 specializes in the distribution and sale of machine tools. Its product range covers from machining centers, lathes, cutting, forging, heat treatment, etc.

Turning, bore and milling in a single operation by a single WFL

The centres of Millturn turning-bore-milling with standard axes B, C, X, and Z allow complete machining of precise and complex parts. With them, the goal of a complete machining and measurement of a wide range of parts to machine with a minimum of parameters on only one machine has been achieved. And, thanks to the interpolation of up to five axes, they can easily machining even surfaces with relief.

Where in the past, many machines process were necessary for machining a piece, Millturn turning-bore-milling centers can now machine a piece in a single operation. In addition, thus avoiding both complicated movements of a machine to another associated with failures of subjection as long time of waiting in front of the machines. Save time and increase the quality are the most important factors to make the costs of production more efficient.

Centre of milling Jobs for machining of tenacious materials

Tarkus is a Centre for milling horizontal/vertical conceived to perform machining of 5 axes of tenacious materials (titanium, inconel, stainless, etc.), with high power and high torque. He is characterized by a unique architecture with a fixed x portico (3.300/4.500 mm) and mobile Crossbeam in Z. This solution guarantees a stiffness constant, especially in the vertical travel Z (1,000 mm).

Tarkus is distinguished by its high-capacity chips, the high dynamics in acceleration and speed boot, the head milling 5 axes continuous dynamic transmission (42 kW, 1500 Nm) or with electrohusillo, the full fairing and the Foundation limited.

Stama machining centres

In vertical machining centers and milling turning, Stama presents specific solutions for customers and the boot sector of chip.

For example, the machining center vertical MC 524, with a surface base of only 4.6 square metres, 'saves space'. The 524 MC is designed for the accommodation of 3, 4 and 5 axis machining devices and is used for a wide range of parts. This range extends from the technical medical, hydraulics and fluid, automotive and environmental technology, to the manufacture of watches and precision mechanics.

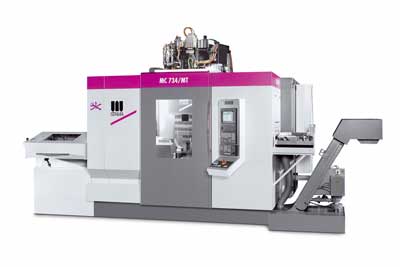

With the development of TM technology, Stama has unified the milling with the turning of a single machining center. The centres of milling turning contribute to save time and reduce the cost per piece, both in lot sizes 1 and Setup 0 times as well as in the manufacture in series - average 70% time saving and reduces costs by 50%. With the MC 734/MT, Stama presents at the EMO exhibition in Milan, Centre of milling turning more powerful of its kind.

Centres with technology Twin, will also be present at the EMO exhibition both in its version of two spindles and four.

With two spindles Twin 600 series, can be machined in one of these centres covers and boxes, oil sumps and buckets of oil, address tree tubes and, of course, also other large components. In the machining of four pieces with two spindles and 3, 4 and 5 axes in a single working cycle, you can reduce costs per piece approximately 30%.

On the other hand, technology Twin2 machined 4 pieces in a single working cycle. The step in the development towards the center of 4 spindles is, therefore, the logical consequence that follows the success of the machining with double spindle. Whether it's one as two areas of work, time cycle and machining as well as the size of lot of the pieces are important criteria in choosing a center of 4 spindles. This machine is ideal for parts with long individual operations.

Studer, specialist in grinders

Another of the represented in Siaisa is the Swiss Studer, which belong to Körber Schleifring GmbH, Division of machine-tool of the Körber AG Group Among the novelties presented highlights model S33, the universal cylindrical grinding machine sold more. Designed for small and medium-sized pieces, now adds new developments that allow grinding of more geometries in a single mooring. This is possible thanks to the new grinding head with two spindles for grinding of external and internal grinding unit.

Also the S22, that can rectify any type of pieces using a variety of technologies, such as conventional cylindrical grinding, grinding of shapes and sizes, grinding of high speed with speeds between 80 and 140 meters per second, or demanding applications with toothache of 160 millimeters in width.The bench of this model is made up of Granitan. The modular design of the S22 allows configurations with virtually all sub-assemblies present on the market.

Another novelty is the model CT960, a universal machine of high performance for grinding of interiors with axis tilt B 91 ° and 4 turrets of husillos. It is ideal for grinding general work and, especially, to rectify complex pieces of materials very hard (carbide of tungsten, ceramics or Sapphire). He is noted for its easy programming and its simulation software that facilitates the implementation underway and reduces to minimum times. The simulation of grinding processes allow an optimization of the process before you start the machine or an external PC. It is prepared to incorporate a transducer of measuring and position.

The CT450L also offers a wide range of applications. It is used for grinding of interiors or for machining fragile materials. The model C450, machine for special solutions, offers even more options than the C450L: the configuration of the grinding spindle and the number of spindles of grinding can be designed to respond to the particular needs of the customers.

What's new with Schaudt Mikrosa

Schaudt and Mikrosa are two brands that also belong to Körber Schleifring group.

Schaudt ShaftGrind S machine is especially designed for axes of transmission of up to 650 millimetres in length. It incorporates bascule spindle. Available programming WOP-S, based on the control panel Siemens 840 d, which helps to generate various easily contours of surfaces. The ShaftGrind S model with its swingarm spindle S2 allows the use of millstones for grinding of different widths and the interpolation of grinding of penetration and recess with a galvanized grinding tooth. This, together with the displacement of carbon from the machine system, increases the productivity of the machine. Among other advantages of the machine is also the fact that can machine materials round and not round up to 650 millimetres in length, with a weight of up to 50 kg. As an option, you can incorporate a hydrostatic guide in the x-axis.

Another interesting model is the Kronos S 250 Mikrosa, which has increased the maximum diameter of the grinding wheel in grinding of 400 to 450 millimeters, thus increasing the service life by 30%. It is a machine designed for tranajar with conventional wheels and CBN, with a range of diameters 1.5 to 35 mm. The spindles of high performance for the grinding wheel in grinding and maintenance-free hybrid bearings allow the use of CBN grinding with a peripheral speed up to 150 metres per second.