Production and PLM systems for the machine tool industry

September 14, 2009

The catalog of software that Siemens PLM Software will present this year at the EMO exhibition focuses on the supply chain-oriented pieces, from the initial idea about the product until the piece as completed. The software fully complies with requirements to perform tasks PLM sophisticated for a wide range of industries, starting with the development of the product using CAD/CAM systems and the generation of programmes for parts through the optimization of post-processor and CNC parameters, and extending to the simulations on line and off line to control and optimize the processes of manufacture on the PC.

"Siemens PLM Software and Siemens Drive Technologies are pioneering by bringing together the worlds of virtual and physical to provide a way out of the market competitive and significant advantages in productivity - machine tool manufacturers and end users of the machine", according to Helmuth Ludwig, President of Siemens PLM Software. "Now more than ever, manufacturers from all sectors need tools to increase productivity, competitiveness and profitability, and solutions from Siemens, connecting the virtual and physical worlds provide tools to enable the correct manufacture the first"", improve the use of equipment and increase the quality of production."

"From a perspective of the users of machine tools, this allows the manufacturer emulate precisely the features, functionality, and the nuances of the process of machining in a virtual environment, prior to physically produce the finished part, eliminating the iterative approach in the workshop", "in the words of Florian Güldner, Analyst Automation ARC Advisory Group.""Virtual emulation is defining the future competitive advantage for manufacturers, providing a means to maximize the Overall Equipment Effectiveness (OEE) use and productivity of production of high value equipment, preserving the resources of capital".

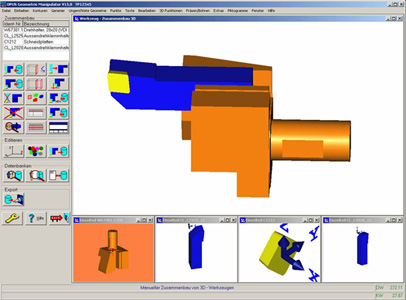

Virtual Machine

Siemens PLM Software will showcase its technology in VM - Virtual Machine-, a copy 'one-to-one' on a PC of a machine tool with full functions of controller virtual Sinumerik and simulation, which will bring an added value both to the end user and the machine tool Builder. This new technology maximizes the productivity of the machine tool to eliminate the need to use the physical machine to the tasks that are not in production. Virtual Machine provides the next generation of validation of NC programming workshop, and the preparation and review of the facility outside machine, thereby reducing errors and the time of configuration, while transforms the way in which machine tools are built and used.

For complex machining operations, you can take a day or day and a half set up a machine tool for a new piece of work, which has a negative impact on the overall productivity of the machine.

The case of the Index Group

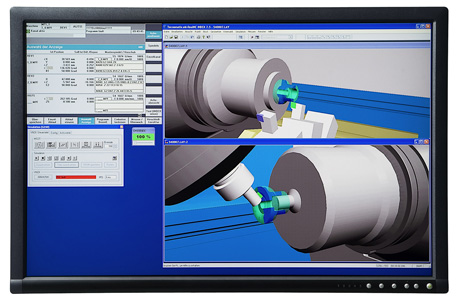

Index Group, one of the main manufacturers in the world of turning CNC machines, wanted to increase the efficiency of the installation, programming and the validation of its production multifunction Center. Index implemented the innovative Virtual Machine of Siemens PLM Software technology to increase the use of machine tools in the work of production, eliminate the collision and reduce setting times up to 90%, without need for additional training.

"The main idea of the virtual machine was installed one copy one-to-one of the machine tool on a personal computer and allow its use as a tool for the operator", according to Eberhard Beck, head of Electronic Control Systems of Index. "The virtual machine is only the beginning." "In collaboration with Siemens, we will continue optimizing the process chain from engineering to production, which is why we will be able to produce even more economically in the future".

Virtual connection to the real and parts manufacturing

In addition to Virtual Machine, Siemens PLM Software will show examples of how to extend chains of engineering processes from product design to machine tools, connecting the virtual world of design engineering and planning with the real world of the plant; and solutions for the manufacture of components that can be applied to a wide range of industries including aerospace, machinery, medical devices, and automotive.

The CAM-CNC connection optimized with advanced post processing is a key example of virtual connection to the real. The NX CAM software provides a better way out of the advanced features in the Siemens Sinumerik driver for a higher quality of finished surface, the advanced tool axis control and a machining faster.

To illustrate PLM from the chain of process of the plant, one of the topics to be discussed will be the moulds and dies, including demonstrations of the design with NX for injection, machining of high speed using NX CAM for NC programming and machining simulation and subsequent processing advanced controller Siemens Sinumerik. The second theme will focus on a piece of complex, representative of the machining of aerospace or power generation, with a process that covers the functionality of NX CAD for the design of parts and NX CAM for the programming of five axes. The selected pieces are mecanizarán in the Emo with a machine-tool of high-speed 5-axis, equipped with a Sinumerik 840 d controller.