Greenhouses: State of technology

July 21, 2009

Materials: Cover

The plastic materials used as greenhouse covers can be classified into flexible films, rigid plates and meshes, although the area covered with the first beats the other two options.

Plastic films used for greenhouses cover usually have between 80 and 220 micrometers (μm) thick * and widths of up to 20 meters. Films can be found in advanced markets monolayer and three-layer. The used polymer, polyethylene of low density (LDPE) and copolymers of ethylene and vinyl acetate (EVA) and acrylate (EBA) butyl represent more than 80% of the global market, which also includes PVC in Japan and linear polyethylene of low density (LLDPE) in the rest of the world. Greenhouse covers have evolved since its launch in the 1950s.

Currently useful lifetime reaches up to 45 months (against nine of a few decades ago), depending on the used fotoestabilizantes, geographical location, the use of pesticides, etc. The standard for films of greenhouse UNE-EN 13206: 2002 'Thermoplastic films of cover for use in agriculture and horticulture' has been published recently and includes instructions on how to measure the time of life, the dimensions, optical and mechanical properties, as well as opaque to infrared radiation; However, does not include information about the behavior of the films on the condensation (non-drip effect or fog) or the effect of pesticides on accelerated aging.

The rigid plates have thicknesses greater than the films, the order of millimeter, and sometimes have alveolar structures. The most commonly used materials are polyester reinforced with fiberglass, the polyvinyl chloride (PVC), polycarbonate (PC) and the polymethylmethacrylate (PMMA). Its use is reduced to greenhouses for cultivation of high value added or when you wish the cover to have a large duration (10-15 years).

The use of nets instead of films as material of enclosure, which do not generate 'greenhouse effect' and yes 'effect Hat' and 'Windbreak effect' is an option of protected cultivation that has some importance in areas of benign winter temperatures, such as the Canary Islands and, in summer, in inland areas of high altitude, as the province of Granada. There is not a Spanish standard similar to the films to the mesh.

The structure

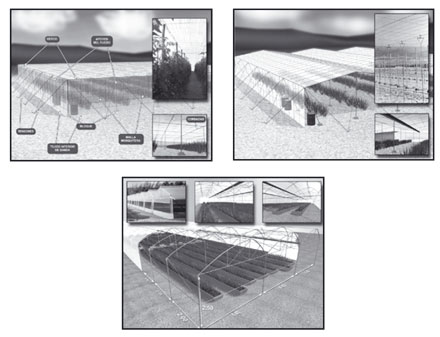

In terms of structural materials, 16 approximately 50% of the greenhouses are metallic structure (galvanized steel tube), while 30% is made of wood and the rest is of structure joint, understanding as such the combined use of laminated wood, metal profiles, etc. Metallic materials have been replacing wood, at the same time that the average of a greenhouse area was growing, still today of about 8,000 square meters. The geometry has gone from the structure flat, frequent

a few years ago, other structures more advanced (Figure 1). Even so, most of the greenhouses still structure flat, although the more being built (55%), is the ' zest and amagado' symmetric, that arises from the structure flat before the need to evacuate rainwater with the symmetrical gabled roof. These two types dominate almost the entire market, which gives an idea of the homogeneity of the geometries and low diversification that they have had so far. The rest of structures is split between greenhouses ' zest and amagado' asymmetric (greater surface plane facing South with a view to enhancing the capacity of capturing solar radiation), multitunnel, macrotúnel and others. By geographical areas, Almería opts for the type structures ' zest and amagado', while Murcia are most abundant multitunnel structures and Huelva type tunnel. The use of greenhouses multitunnel in all geographical areas is more widespread for ornamental crops.

The aspect that more has changed in the geometry in recent years has been the growth in the average height of the greenhouse. This translates into an increase in the unit volume (m3/m2), so that increases the inertia of the greenhouse to the changes in the different parameters of the climate (temperature, humidity, deficit) of pressure of steam, carbono… dioxide and dampen the sudden changes in these variables. The increase in height also has a positive effect on the natural ventilation and makes the greenhouse more functional and capable of adapting to active and more suitable for his possible mechanization air conditioning systems. The average height of the latest greenhouses is 3 to 4 m, compared to the 2.5 to 3 m's twenty-five years ago. The width of the chapels (each of the ships in which the greenhouse is divided) varies from 6 to 8 m of the symmetrical front of the 12 m of the asymmetric.

Substrates

One of the techniques that has most influenced the development of agriculture under plastic has been the sanding. This technique involves in the incorporation of a layer of sand about ten centimeters thick on the ground, which confers significant advantages: the sand creates a microclimate favourable to the plant, since it alters the balance of water and energyincreasing the temperature and stimulating photosynthesis. The soil moisture is also preserved for a longer time due to the reduction of the evaporation, thus saving of irrigation water.

Along with the sanding, crops in substrate (middle of artificial cultivation on which grows the plant) are an interesting alternative with a rapid growth in the last ten years, reaching 20% of the surface in Almería. The most common substrates are the Rockwool (9%), perlite (10%) and coconut (1%). Peat is also used as black, with higher content of organic matter, such as blonde, more inert. There are substrates suitable for the various species, which combine mixtures of different substrates depending on the needs of retention of water or duration of crops to ornamental crops.

There is a trend towards the introduction of crops in substrate in greenhouses of recent construction, reaching 50% in less than five years old greenhouses by the lowest initial cost from the sanding. Also the pure, without substrate hydroponic, being introduced in crops such as strawberries, although its surface is still limited.

Electromechanical systems: mechanization

Under greenhouse horticulture has been characterized by intensive agriculture in hand work faced with a relatively low level of mechanization. Currently 40% of farms has with tractor and, although 10% have more than twenty years, the incorporation of tractors is increasing in recent years. Tasks of maintenance of the soil, plant protection treatments, transport of the crop within the exploitation and, to a lesser extent, the transport of the product to the center of marketing are covered with them. There is currently a significant growth in the incorporation of auxiliary machinery for farms, aimed at improving productivity in work on transport and the production load. The greenhouses for ornamental crops in general have a degree of automation outweigh the of vegetable, with systems of movement of plants in the greenhouse or traceability from the seed to the final consumer by barcode.

The most widespread system for the application of phytosanitary treatments is the spraying, using facilities fixed, present in more than 85% of the surface under plastic. In recent years there has been a very important growth of the air sprayers (guns).

The air conditioning

In Spain air conditioning systems and active cooling or heating are fairly scarce, although in other cooler areas or with higher added value crops, for example ornamental, these are frequently asked. Most used heating systems, for being the cheapest are generators of hot air (direct and indirect combustion) and systems of pipe that circulates hot water average temperature (30-45 ° C). Under-utilized are the systems based on conduction of water at high temperature (80-85 ° C) for metal pipes, due to the high cost of initial investment. Greenhouses heated more frequent are the greenhouses or multitunnel, of high altitude on a ridge (highest point in the greenhouse) and less than five years old. Its surface is also above the average (8,900 m2), belong to large farms are always electricity and the technical level of their owners often also higher than the average.

Lateral ventilation systems tend to be folding or retractable banner window (flexible window is rolled up or folded on one axis). The overhead ventilation often be sliding band, flip-up window (rigid window which revolves on an axis to open and close), retractable banner or without ventilation window. The automatism in the drive of the Windows, either with independent Motors (semi-automatic systems) or developers of climate (automatic, with wind and temperature sensors) is insignificant with respect to manual control systems, but continues to grow.

Cooling by evaporation of water to lower temperature and increase the humidity in greenhouses is an alternative that is beginning to be used. The equipment most recent deployment and with more possibilities for expansion are nebulisation or water spraying systems.

Fertigation

Fertigation is the application of simultaneous form of fertilizer and irrigation water. Fertirrigation met a number of drawbacks that made difficult the management and the application of fertilisers through the then novel system of drip irrigation in its early days. Traditionally used fertilizers for the implementation on the ground had characteristics that limited its use in localised irrigation systems, which are those that provide water to very specific points, usually near the roots of plants. Such features were its low solubility, which caused seal of drippers and filters; the large amount of impurities, which prevent the control of inputs and desvirtuaba values of salinity or conductivity of the water for irrigation; uncompensated formulations (rich in certain elements which, even though they are required for crops, in excessive percentages are harmful). There is currently a wide range of fertilizers soluble, with a high degree of purity and a variety of formulations can be adapted to the needs of the crop in each phase of growth.

Parallel to the development of suitable for Fertigation fertilizer, there have been significant advances in filtration systems, which have resulted in new materials resistant to corrosion, improvements in the design and manufacture of the filter element (mesh of high reliability)(ring of precision microrranuradas...) and appearance of automatic filtering systems, to ensure the continuous cleaning of the system.

Drip irrigation is a technology that was imposed during the 1980s and now use it almost all the invernaderos.16 should be noted the important renewal experienced by irrigation drip: 80% have less than ten years and 55% less than five. In parallel, there has been an improvement in the quality of the drippers: 80% of the greenhouse presents an excellent uniformity (more than 90% uniformity coefficient). The consumption of water per hectare per year has become in Almería from 7,000 m3 in 1982 5,500 m3 today, with an average economic efficiency (value in on-farm production) 9 euros per cubic metre of water used.

However, the major contributing factor to the high efficiency in the use of water for the crops under greenhouse is the lower consumption of water from the same crops in the open air. The plastic cover reduces water demand due to the reduction of solar radiation and confinement, which limits exchanges with the external environment. In regions with high sunshine greenhouse can reduce the consumption of water by up to 50%.

The head of irrigation is an important component both by their initial investment economic impact and role in fertilization. Although each system is different depending on the needs of the regante, it usually includes a pump, filters, fertilisation equipment and elements of measurement and control unit.

The system of incorporation of fertilizers is one of the greatest importance. The most common types are usually the abonadora (system where fertilizers are dissolved by water that flows through an auxiliary tank) (50%) and the 'venturi' (system where fertilizers are directly injected into the flow of water from irrigation with a suction system)(: 35%), although the former is older. Manual fertilization system is linked to the anecdotal presence of some greenhouses with irrigation on foot. The abonadora and the direct absorption are obsolete systems, since the incorporation of the fertilizer is produced in a variable manner over time resulting in oscillations of the electrical conductivity of the water for irrigation. Currently the most installed systems are type 'venturi'.

Another factor of growing incorporation is irrigation Scheduler, present in more than 30% of the greenhouses and linked to the growth of the area of cultivation without soil. 86% Of developers was installed less than five years ago. More than 80% of the farms has a raft of irrigation, with a capacity of 2,000 m3. For the most part they are built with concrete, but tends to use more and more plastic geomembrane. All the greenhouses, except for the flat roof, allow the collection of rainwater and leadership to the raft if you have the appropriate conditions. It is estimated that a good system of rainwater collection can cover a significant percentage of the water needs of crops.

Auxiliary biological systems: Polinizadores

To obtain a good harvest in fruits and vegetables of fruit, it is necessary that the flowers polinicen. Transport of the pollen can be carried out by a physical agent, if the wind, or a biological agent, such as insects. Protected cultivation need help so that there is an optimum pollination, being one of the most used methods use of bumblebees. The introduction of these insects on crops under plastic, since the end of the 1980s, has increased and has been accepted by farmers. This has been due previously pollination was with electric vibrators or hormones, still very laborious and high cost of labour. Currently, the use of bumblebees in glasshouse has allowed to reduce costs of production, improving the quality of the fruits and making that the use of plant protection treatments has left in the background to make way for the introduction of organisms for biological control for pest control.

Integrated production

Plant health control has always been one of the battle of the agriculture and thus to be producing technological innovations, is have tested applications in this regard: in the early 20th century experimented with electrical currents, electromagnetic fields, different types of radiation, frequency, etc. But which offered no doubt a resounding result was the advance of the chemical industry, producing a great development in agriculture from the second half of the century, progress marked undoubted successes and also quite a few difficulties. One of these difficulties is the loss of effectiveness in the control of pests due to the development of resistance to the active ingredients used. In recent decades agriculture has brought serious pollution and degradation of the environment by excess pesticides and agrochemicals in general. From the 1990's concern for the preservation of the environment and public health is contained in the legislation of the various European governments.

There is thus a reform of agricultural policy based on preventive approaches that promote sustainability and recognizes the dual role of farmers as producers and protectors of the environment. The proposed objectives include reducing the use of pesticides and the conversion of farmers towards methods of integrated pest control. To achieve these objectives, in the different Spanish autonomous communities apply agri-environmental aid, whereby farmers receive compensatory payments in exchange for certain agricultural practices. These measures include subsidies to promote integrated production and organic farming.

On the other hand, the concept of certified production refers to the production according to a determined and certified by a standardization body. In Spain there is the standard UNE 155001 ' for consumption as fresh vegetables. Controlled production '. Currently, more than half of the surface of greenhouses in Almería is certified by any of the existing quality standards. The hectares covered by the standard UNE 155001 have grown rapidly in the last decade, although it seems that they have stabilized around 11,700 hectares. This surface should add the certified by organic farming, integrated production (uses natural and synthetic products insofar as they are respectful with nature) or by EurepGap, mainly (program private certification consisting of increasing consumer confidence in food safety by developing "good agricultural practices" to be taken by the producers). It highlights the major expansion of the biological control that has taken place in the southeast of Spain, in the Campo de Cartagena since 2001 and in the past two years in Almeria. It has gone from a few acres with integrated control in the 2005-2006 to 1,400 hectares campaign the following year, and to more than 11,000 hectares in the last campaign 2007-2008.