The components are not stupid, machines not

July 15, 2009

In the not too distant future, the technique of sensors in planetary gear could be something as common as the ABS or ESP in the construction of automobiles: equipped with a built-in intelligence, these gears literally can 'listen, feel, think and communicate' and, thus informing at any time and reliably to the owner of a machine or installation on the current state of service. For example, the subsidiary of Wittenstein, alpha getriebebau gmbh, located in the town of Igersheim, offers Planetary gears of game also reduced with an intelligent technique of sensors.

The idea of the supervision of the process with the help of smart drive components is based on the fundamental reflection that a gear is the standard component closest to the process settled as a bottle neck between the application and the drive in the flow of the branch of drive force. In this sense, for technicians of drive, everything that comes behind the gear is part of the process. Pass through the gear mechanical efforts: transverse forces, pairs of shift, number of revolutions and vibrations, as well as efforts to heat, wear and play.

Like the standard component closest to the process, the gear is required to 'share everything', usually without complaining, so that the owner does not receive any information to know if the drive is subjected to excessive or insufficient efforts. A smart technique of sensors, as says Heiko Haag, responsible for the development in the technique of sensors of Alpha, "makes that the gears so far were blind and dumb to communicate now in detail." "Planetary gears offer a direct and immediate information to the owner: a visual window on the process".

The case of the presses

Eccentric presses are examples of a number of successful applications. He has been a clear improvement of the production process through the technique of sensors of transverse strength and the measurement of the strength of pressing in real time. One of the first sensory Gears has been used in a gantry milling machine. In addition to the technique of torque and three sensors of temperature sensors, it also has a web server for the availability of measurement data over a TCP/IP connection.

The capture of the State and an intelligent influence create transparency

Production systems are becoming increasingly complex and increasingly to themselves should be monitored. On the possibility of installing 'know-how' and experiences in order to avoid handling errors and make the machines more intelligent, Friedrich Kilian, Manager of Trumpf GmbH + Co. KG, Ditzingen, and head of the Department of central purchasing, as well as research and development for machine tools, says: "There are different answers, depending on if talking on a single machine or a complete line of production or chain of processes." In the case of the machine itself, we are trying to reduce necessary lessons that must be the operator. "The basis here is always a collection of the State of the machine."

In addition to the intelligent on the same machine components, in the opinion of Kilian there more potential optimization throughout the chain of processes. Important here is supervision with control software "that allows to plan and control all orders for machine and production." "Our software offers ample opportunities for communication with PPS and ERP systems, programming systems, controls of the machines and store systems". In addition, control must provide a simple and objective-oriented management, as well as an optimal support of the machining process. This is the reason why Trumpf not only develops on their own control, but also the interface of management of own machines.

The machines should be smarter

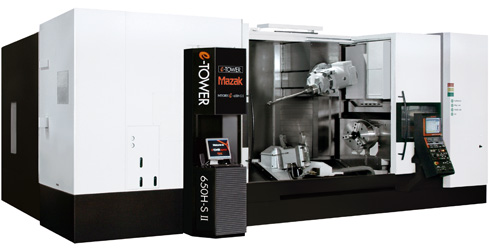

Also the Japanese manufacturer yamazaki mazak "cares on an ongoing basis for the development of modern machine tools", it says Wolfhart Kästner, head of marketing of Yamazaki Mazak Deutschland GmbH, Göppingen, which is shown in the vision of the digital supermáquina. This type of machine, this is confirmed by Kästner, "occur in 2019, which is precisely the year of the 100th anniversary of the founding of the Yamazaki Mazak Corporation".

Of Mazak machine tools with their intelligent features "stand out for their productivity." "These functions are achieved because it supports the operation of the machine to such an extent that the operator has to deal with a much lower number of tasks". In the case of these calls 'i-máquinas', intelligent functions are part of the standard equipment. Depending on the type of machine, Yamazaki Mazak has now integrated up to seven intelligent control of the machine functions.

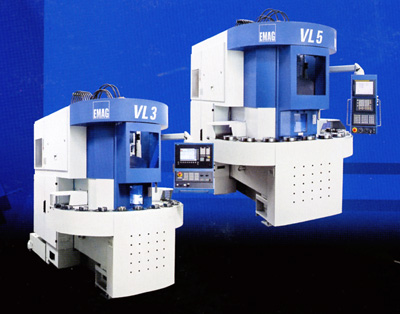

Also for Andreas Mootz, Manager of emag salach maschinenfabrik gmbh, there is a range of possibilities to make the machines more intelligent and to install 'know-how' and experiences: "this process begins with the maintenance plans which are memorized in the machine and are able to emit warning signals automatically from" maintenance or maintenance requests. "We dedicate many resources, for example, to provide a view oriented to the user by means of screen custom masks to facilitate information and tickets simple and clear in relation to the production system".

The question about the advantages and disadvantages of centralized or decentralized intelligence answers the Emag Manager ambiguously: "doesn't make much sense increase the complexity of a production system with many additional components." "The best sensor is which is not installed." It makes more sense to take into account the quantities of State control and drives for the supervision of the production facilities.