Interview with Carlos Pujana, managing director of Izar Cutting Tools

April 7, 2009

Izar is a company that attaches great importance to the Social responsibility of business. They have recently made a financial contribution to the NGO Médecins sans Frontières. Tell us about this shift in its strategy, as well as other social projects where Izar has been inmerso…

We started to work on CSR several years ago, in fact, our commitment to CSR was recognised in 2006, with the granting of one of the first degrees of commitment from the Biscay Forum of CSR. In that event we agree with several large companies like Iberdrola, Eroski... but we were the only industrial company of our size, which filled us with pride.

We pursue two objectives: on the one hand give back to society part of how much that gives us, and on the other hand, increase corporate pride of our employees to work in a responsible.

CSR is in the DNA of the enterprises of social economy such as ours, starting with the own generation of employment. The economic contributions, such as the one made to doctors without borders, fall under the chapter more anecdotal, if you will. In any case, our main contributions are made for cultural and sporting projects in our immediate environment, and another portion goes to projects of international cooperation, as mentioned, not to mention our cooperation to 3 years, with the Unicef Niger projectto put an end to child malnutrition in this country, in cooperation with Asle.

The month of January, held its annual Convention, what conclusions were obtained? What policies run the company soon?

In the Convention of the month of January, we concretely, on the one hand, to publicize the facilities of the new company at full capacity to all our partners, and on the other hand, analyze last year 2008 and share trade policy in the face to 2009. We also had a broad discussion on the current situation of market and future prospects, giving rise to a strong involvement of all partners in Spain, France and Portugal.

The main conclusion is that we must work twice to check the same, so our partners claimed an aggressive commercial policy of intensive market presence with new catalogs, both of Izar industrial of IzarPoint construction company, with launch of new products to meet the demands more demanding market.

We reduce costs internally, but never trade costs. We want that our customers will appreciate the strength and the strength provided by Izar, as a supplier today, but also for future.

In the current circumstances of the market, more than ever if possible, must help customers with products that solve problems, which are not necessarily the cheapest, so... are the Chinese.

Izar Cutting Tools last year earned a turnover of EUR 22.200.000 what is the key to the smooth running of the company?

They could have been a few euros more, have not been affected by the move to our new production plant. It must be borne in mind that during the peak of the market (how far now seems!) we had to move more than 200 people and 300 machines, while continuing to serve our customers, a single day.

I think that a solid value proposition we bring to our clients: we perceive as the leading manufacturer and one of the most important at European level. We provide quality products that solve their problems at a reasonable price, with an excellent service, 99% of lines served on the same day in national market today and we continue to make news, even now.

Our customers also perceived closeness, value their contributions, and fundamentally perceived strength and future, in the times, it is not little.

Can you explain in detail the policy of hoist of diversification of their products?

In its beginnings, back in 1910, Izar, in addition to manufacturing components for the automotive industry, such as the docks and crossbows, manufactured and marketed, (drill bits, males and strawberries) cutting tools for industrial uses.

The first step was the separation of both activities, automotive on the one hand and on the other hand cutting tools. The current hoist is heir to that part of cutting tools original, which was gradually focusing their productive effort on those products that had a real competitive advantage, and selling the rest, always in the field of metal.

14 Years ago we launched also market a new offer for the sector of the construction, with the IzarPoint brand. Imagine not then the deep recession that would come to this market, but not the huge development of both catalogues today.

We have gone from selling products to sell solutions and an example of this, they are our modular presentations to the point of sale help sort and display the product, working with it for the sale.

By giving a Ribbon of the importance of the manufacturing for Izar, today, 75% of the turnover is made up of own manufactured products.

Do provides similar figures for 2009 despite the current picture?

It will be very difficult that we can repeat the figures of turnover of 2008 in 2009, but we will work very hard to achieve this, both in our domestic market and export.

We will be launching new products, approach to new markets, in addition to the 66 countries in which we are now present, and strengthen the bonds of loyalty that unite us to our customers and suppliers.

In any case, it will be very difficult that we leave the current situation before the end of 2009. It will have to monitor the debt and potential bankruptcy situations that may occur, among distributors and manufacturers and that should clarify the market in the second half of the year.

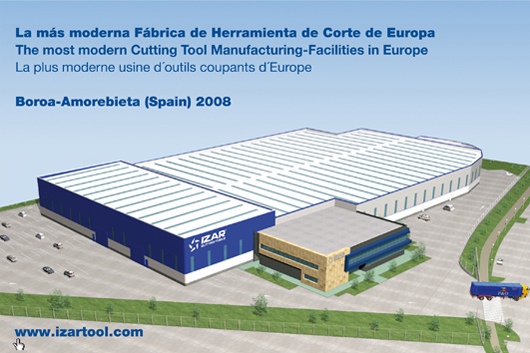

Considered by many "the most modern plant of Europe", the new facilities of Boroa are already in operation. What has it meant this change for the company?

As you know, we opened new facilities at Boroa in March 2008, in an emotional and multitudinous Act that we have with customers, suppliers, employees, authorities and media, but they were not fully operational until the month of mayapproximately.

During the fair of Ferroforma we also take to organize visits aimed to teach the plant to customers around the world and we surprised the huge acceptance of these guided tours. To such an extent that very qualified personalities at the international level, have conveyed us that we have been very modest when it comes to qualify our new plant, that from his point of view is not only the most modern, but "the best in the world".

The new plant, not only provides significant improvements in productivity and quality of life for our employees, but it essentially is a guarantee to face the future with more confidence.

What they consider 'the most modern in Europe' it? I.e., do they have invested in new media production, improved automation, improved logistics...?

Firstly, because the last factory opened in Europe and in the world, having worked in a specific process of plant design for more than 2 years. We have invested 15 million euros in this project, including the acquisition of the land, the building and facilities.

In any case, and leaving aside the quantitative aspects, even though very important, we must take into account the qualitative, such as: the redesign of the plant on the basis of the most modern concepts of the 'lean manufacturing', to gain in agility and flexibility and have developed some simple maintenance facilities and respectful with the environment. In this regard, stresses the system for the use of heat produced by the own factory, among others.

In addition to the investment in building and facilities, we have continued our investment project in machinery and during the last five years we have invested a total of EUR 5 million in new machines, automation of processes of manipulation, improves warehouse logistics, etc. This rethinking of our logistics has led us to very significantly improve service ratios, after having been penalized by the transfer.

Specifying a little more, talk to us of the activity of Izar for the metalworking industry.

Since its inception in 1910, the activity of Izar has been directed mainly to this sector, to become the leading manufacturer, based on our wide range of drills, males and cutters for metal and our excellent service.

Over the years we have been evolving, complementing and extending our range of products and evolved from the sale of products to the solutions to the needs of machining for our customers. The result of this evolution, is the approach of our catalog, based on the types of materials to be machined.

How can you help a good tool to improve the production process in a workshop of machining?

First, it must begin by determining which is the right tool for the specific work and the material on which will be carried. This seems a no-brainer, in many cases is not done by ignorance or a wrong approach to savings on tools, which can lead us to use a same tool in different materials, such as for example, a titanium or stainless austenitic alloyWhen both materials need tools of totally different geometries.

Therefore, we have designed our catalog based on applications and in the responsible use of the tool, and have a service factory to this support the machining, as well as to develop special for each specific application tool. You can save many hours of work, with the choice of the right tool for each application.

The materials are a key part of the tool

Indeed, in addition to the geometry, the quality of the materials that are made, as well as surface coatings that can be used in each case, are fundamental in ensuring adequate performance of the tools.

Fly only works with the main European aceristas, between those who have a fundamental weight Böhler-Uddelhom and Erasteel. The materials with which we work are: fast steel or HSS, M42 and M35 cobalt steel pulvimetaúrgico or PM and integral hard metal.

Given the weight of the materials for the whole of the tool, precisely, have launched two new catalogues for materials of stainless steel and hardox, does include what's new?

Deepening the orientation towards applications of our tools, we have identified two very concrete areas of materials difficult mechanization in those who want to offer innovative solutions that provide a competitive advantage and a differentiating factor on our competition: stainless steels and hard materialswhich include the Hardox.

We have launched two specific brochures for these applications, which in addition to explain the main characteristics of these materials, we recommend the right tools for your drilling, threading and milling and ideal working conditions that should apply in each case. This has led us naturally to the design of new tools, such as a new Strawberry of roughing for austenitic stainless steels and a new drill for Hardox.

Us has pleasantly surprised the high demand and acceptance of these brochures from our customers, and also its demand that we go beyond, with the design of special tools, in addition to our classic offer of Strawberry mother to carve gears.

The drill bit flat drag the stainless steel with three-oriented multipurpose and special anti-wear plate and Hardox drill are two of the latest products that have been released. Tell us about them. In addition, what other news have launched on the market for this sector?

These two new bits are perhaps the most striking aspect of the new product range introduced in Ferroforma. Both are integrated within the new special applications brochures mentioned above: stainless steels and hard materials.

The drill bit new Multinox is a drill bit of careful surface finish and keen autocentrante, specially designed to work with hand drills. Its special geometry, allows that the drill work not only in corrosion-resistant materials which increasingly seen in the market, sectors of food, chemical, transportation, etc., but it is also an excellent universal drill for the most demanding applications.

Its handle has three flat drag, allowing an ideal setting in the Chuck, even in the unfortunately common case, in that the claws are worn. These planes, therefore, prevent the drill bit patine durante su utilización.

Finally, the new high-performance for Hardox drill is designed to work in column drills, this material ever used more, as well as sheet metal antiwear in construction, such as armor on vehicles of all kinds. It also has a neat geometry, with keen autocentrante and the innovative coating Alcr.