Tekniker-IK4 at Biemh 2008

February 21, 2008

The Basque technology centre Tekniker-IK4 presents three developments in the areas of industrial robotics, high-performance electronics and advanced manufacturing technologies as a small example of its capacities. The most striking Tekniker-IK4 stand proposal is a scenario where industrial and mobile robots that integrate machine vision systems and other sensors to achieve complex tasks are coordinated.

Through a game, Tekniker-IK4 visually explains its ability to develop a concept for the future of the robot autonomous, in which machines respond intelligently to the changing environment and interact in a natural way. It is situated in a privileged position in providing services in industrial robotics and in service.

In fact, Spain is the seventh country in the world in number of robots installed and it has more than 60 groups of research in robotics, but paradoxically that does not have a robotics industry beyond engineering distributors and installers of robots.

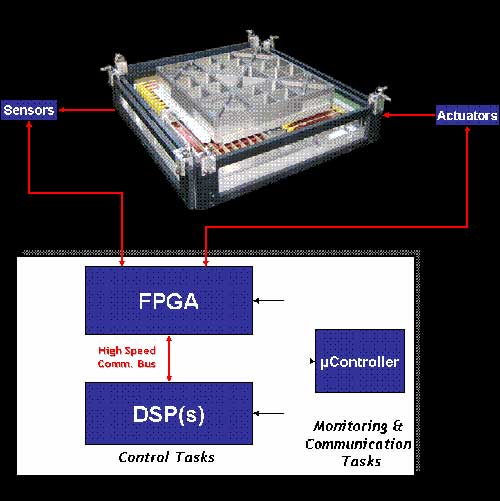

Hybrid hardware platform

The device offers a very high capacity of processing and data capture that allows the implementation of complex systems, such as for example the of magnetic levitation. The platform also offers possibilities for exhaustive monitoring which allows to control engineers know the behavior the system at all stages.

Through a combination of technologies, application of Tekniker-IK4 obtains a performance far superior to conventional control systems are able to offer, both in terms of computing power and speed of response and number and quality of input and output channels. The system is capable of processing to five cycles of filtering input channels more PID to a frequency of 250 KHz, while the main competitors offer a cycle of 60KHz for single-channel PID.

Processes with ultrasonic and laser techniques

The processing laser, deals with the micro-mecanizado of parts with complex and precise details, the texturing of molds and components for improving their tribological performance, the recharge of critical areas such as protection, anti-wear and anti-corrosion, repair of metal piece, heat treatment & weldingIt flows into the final adjustment of laser equipment for various industrial applications.

omplementariamente, Tekniker-IK4 also delves into new technologies for the manufacture of chemical nature as PECM (pulsed electrochemical machining), as well as monitoring and simulation of different manufacturing processes as a basis for his study and optimisation.