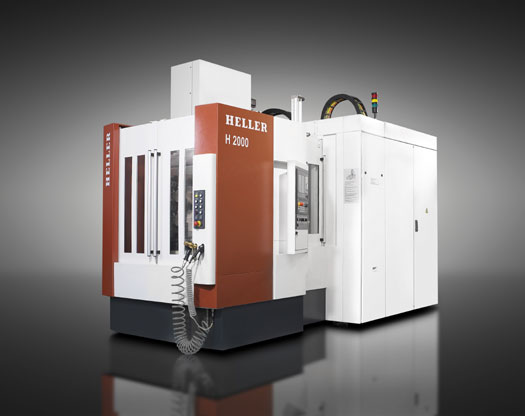

Heller Machines, in the Biemh 2008

February 17, 2008

One of the objectives of the development of the new line H era increased performance and accuracy, which entails an improvement in the productivity of the machine. This did the development engineers of Heller through optimized structures of castings, bench and column with a stiffness static, at the same time with a minor for a dynamic weight extremely high. This is reinforced in the 2000 H, 4000 H by a double the z-axis drive, as well as a direct measurement system absolutely encoded in all axes.

The result is visible: despite a surface floor clearly minor, dimensions and maximum weights of parts to machining exceed those of the previous models.

There were improvements in the aspect of continuous operation: vertical walls in the area of labour guarantee an optimum fall of chips below the spindle. A width 600 mm extractor is able to evacuate a large number of chips of the workspace.

Novelty is also a mechanism of cleaning of the spindle in the change of tool. Now is by aspiration, instead of blowing tools cooling channels: This saves in coolant and reduces time of change.

Great performance for less money

The customer chooses: individual settings or package

In all versions, Heller offers its already prized system of spindle based on the own development and production of the Heller system of spindle work (Nullspindel).

As regards work cones Heller offers the possibility of both Mount HSK 63A, ISO 40 and BT 40.

Equally flexible is the new H series management tools.

The standard machine already comes with 54 posts tools in a store chain, which can be extended to 80 and 160 jobs.

The loading and unloading of tools is possible while still working the machine. The tools can measure up to 450 mm in the H4000. Times of change of tool chip to chip according to VDI are according to the model 2 to 3 seconds.