Fresmak, in the Biemh 2008

February 16, 2008

Fresmak-Arnold is committed to providing the optimum mooring in addition to the continuous technological development of new machine tools.

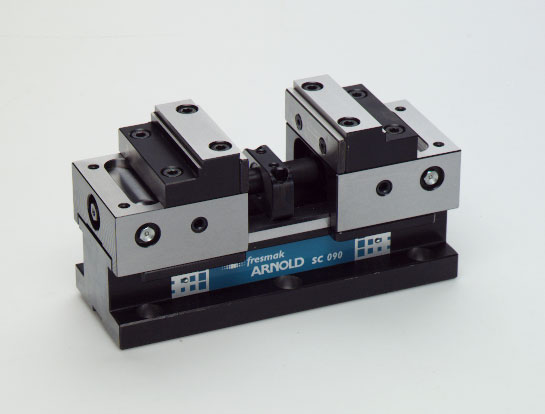

Arnold SC

On the one hand it's a self-centring muzzle which is a great help in coding this kind of machines where the risk of collisions is much greater than in any other. On the other hand, its design was made in order to allow the machining of the parts by the largest possible number of faces in a single mooring. The piece is tied to a high enough to facilitate the rapprochement of the head without obstacles.

The spindle is located above the guidelines of sliding approaching the mooring as much as possible to the point of action of the transmitter spindle of the force. The result is a safe mooring with minimal deformation of the mouths.

It's a gag of contained size, but precision.

It occurs in two models of 90 and 125 m/m of width of mouths. A new gag like no, Fresmak has decided also to patent in the European market.

Gag Arnold Automat

The gag Arnold Automát. It is a new and revolutionary version of the jaws óleo-dinámicas that exist in the market. This clamp allows to achieve 4.5 t of mooring with only have 70 bar pressure of oil and also has a Tour Auto of 4 m/m of forward and backward to facilitate the exchange of piece. It is a unique international market muzzle.

Such is the progress reporting, which Fresmak has decided to patent this model at European level.

Arnold IZ1 - Arnold IZ1

Does not have any similar with what Fresmak has been released so far, because it is designed for the work of long series of pieces of small size. This standard Vice, can work with mouths machined according to the geometry of the parts.

Although the presentation is made in a uniform manner, with this model of gag it can work in a space with several units inserted in a single block.

The gag IZ2 is a variant of the model IZ1, what the difference of the above is that it is a cheaper model and providing a higher route than the previous. It is a model of gag automatic, with a great versatility and completely watertight to chips and coolant liquids. It has an automatic travel of 35 m/m and offers a force of amare of up to 2 t oil pressure 250 bar.

This gag is presented individually or in a set of several of them in the form of homogeneous bloc, without any type of hose. This means, for example, a set of four moorings of this type do not meet the 20 kg and they can be placed on machine without cranes. This makes them very versatile, to work in the machining of small centers.

Arnold approx. clamp

To improve the ergonomics of work, Fresmak will present the Arnold - approx. clamp.

Usually the gag within the machine, has been placed to date with the mouth fixed at the bottom of the table in the centre next to the column of the machine. To position the workpiece in the clamp when this is heavy or an important volume, it requires many times the use of a small grúa-pluma, or failing that to a great effort from the operator who must stretch his arms with the piece caught with their hands.

This new model of gag Fresmak presented in this show to the world market, has the originality that fixed mouth is in the area closest to the door of the machine and the spindle has the handle in the front of the gag just on the side of the operatorwith which, placement and mooring are made in a manner as possible to ergónomica.

Hydraulic cylinders

These cylinders are part of the range of elements of mooring Fresmak used in tailor-made projects for their clients and are exposed in the BIEMH 2008 fair.