AutoForm at Biemh 2008

February 10, 2008

These decisions take during the phase of planning and have a direct influence in the final cost. In addition to that any rectification realizar in back phases will increase the costs of significant form, is thus that it is vital to take the suitable decisions from the first moment. The manufacture and the phase of tuned of a game of coin big carries between 9 and 18 months, by what the correction of the errors of planning can suppose several weeks of work and costs in the order of 10.0000 . It is more, simply a deviation of a 5 percent in the calculation of the costs of a big game of coin comports a cost associated extra of 10.0000 . Up to now, the costs of matricería realizar using mainly leaves of calculation, what supposed that the user had to enter a lot of data manually so that there was not neither transparency neither repetitividad, what did that it resulted a quite heavy process. Thanks to the new solution of AutoForm can evaluate quickly alternative stages of production and take the dediciones suitable from the first moment.

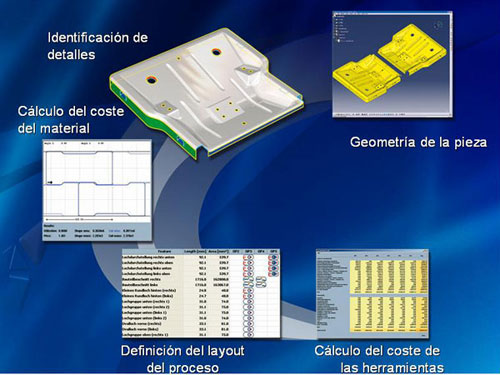

The program works with the geometry of the piece in 3D, and detects automatically the peculiarities of the piece like holes, contrasalidas, etc., that allow him propose an intelligent sequence of manufacture that the user can modify easily. When identifying automatically the details of the geometry of the piece, the structure of costs is totally transparent for the user. To facilitate this work, the interface of AutoForm is amicable, and has of functionalities to puncture and drag to define of the layout of the process. To obtain the results simply is necessary to presses a button.

Workflow with AutoForm-CostCalculator

The main benefits are the reduction of time and improving accuracy in the planning process. Other strategic advantages are the integration of data from planning of production, cost calculation, surface design and simulation of processes, under the same system.

Thus ensures the consistency of the data, avoiding the work two times and faster defines the concept for evaluation within the company and the client; In addition to providing a rapid response to decision making.

AutoForm-CostCalculator quickly identifies the sequence of that optimizes costs, saving money in the tooling and manufacturing provides the benefits of digital manufacturing: integration, transparency, standardization and reproducibility.