Bernecker & Rainer presents ACOPOSmulti, cheaper version for the control of servo motors

February 4, 2008

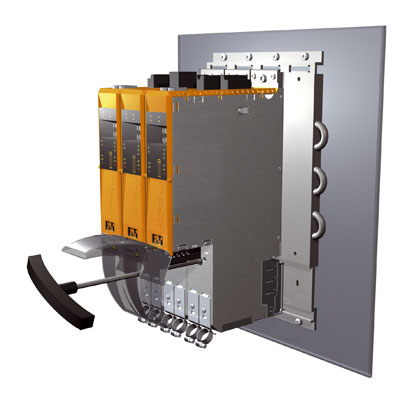

Heat dissipation is available in 3 variants: standard, with radiator and water/oil.

ACOPOSmulti is the optimal solution for multiple axes machines, widely spread in sectors such as packaging, plastic, textile, printing or robotic. It occurs as a team technologically range very high and respectful with the environment thanks to the optimization of its consumption.

Waste energy in the electrical panel is a thing of the past

ACOPOSmulti offers different solutions for dissipating heat out of the control panel. The user can choose between a backplane with dissipation of heat out of the control panel and protection IP65 or a backplane for cooling water or oil. Thus avoiding the use of internal fans within the own box.

In addition, ACOPOSmulti transforms in the most efficient manner possible electrical energy in mechanics and vice versa. Rather than convert kinetic energy into heat during braking, it makes electrical energy returning to the network. In this way, and thanks to this integrated regeneration system resolves warming within the electrical panel in an intelligent way and in line with modern environmental standards. Another important advantage is the aspect of the correction of power factor: this system is capable of generating the active power from feeding, greatly reducing the total power consumption and load of the machine (approximately half). This also brings as a consequence fuses and minor diameters of wiring.

The power supply of ACOPOSmulti also connected via a field bus control, therefore offering all kinds of information related to the diagnosis and management of the same; It is a very interesting innovation that allows to develop forms of predictive maintenance.

Built-in 24 VDC power to avoid voltage drops

ACOPOSmulti integrates feed 24 volts for the electronics of the servocontroladores for both PLCs, PCs and I/o are connected on the machine. In addition to minimize space and optimize costs, this feature allows you to manage teams when there is a drop in the voltage on the network.

All the other teams are therefore directly connected to 24 volts, being protected against open circuit, short circuit and overload of stress. Joined a bus for communication in real time as fast as Ethernet Powerlink, this functionality allows to reach a State of stop in a controlled way.

In addition, simply insert the modules to the backplane and ensure two screws to connect to the feed. In addition to the 24 volt power, the grounding may also be done without its being necessary to make additional connections.

Insert and screw: food and the land the taking by the backplane

Integrated security

Some new solutions of security in the market are based on field bus are not standard or that have answers times too high. The ACOPOSmulti system brings the advantage of the open and standard technology of Ethernet Powerlink Safety, which uses effectively. Security with ACOPOSmulti allows to implement following features according to the Cat.4 of EN954-1 and SIL 3 of EN61508-1: stop controlled or free; limited maximum position; limited maximum speed; and direction of rotation fixed.

Other basic functions such as 'necessary rearmament after stop' and the output that activates the brake of the motor (both according to the Cat.4, EN 954-1) are part of the standard envelope.