This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Más rápido y con más precisión(Wire EDM)

Faster and more accurately

Theophilus Paris. Manager of Suntec machinery technique, S.L.15/04/2002

The electrochemical procedure of penetration further developed PEM currently allows profitable mechanization of miniature in almost all the metal structures.

Faraday laid the foundations: first came a surprising hum, then a frenetic Ovation through all the Hall of conferences of the Institute Royal London. Michel Faraday ended his first "speech of the Friday night" with the experiment of the transformation of the magnetism into electricity.

The self-taught who came to the world in London, 210 years ago, discovered the induction without any academic preparation, and introduced her in front of experts.

So far all knowledge are linked to the "Faraday cage". The knowledge that Faraday had even when the English did not have the capacity to shape and define them mathematically is surprising.

He also had great success in the then new field of electrochemistry.

He investigated the chemical effects of electricity and formulated the laws of Faraday. He defined the relationship between fluid flow and the amount of material removed at the poles. Faraday's we have been the concepts electrolysis, electrolyte, electrode, anode and cathode. We continue the short history of the development of electrochemical boot procedures.

Many years after Faraday, in early 1920, Pirani and Schröler developed an electrochemical process to make holes. Later Gusseff patented in 1930 an electrochemical procedure of penetration in wet. The first industrial applications in difficult machining materials occurred during World War II and in the 1950s in the aeronautic and aerospace.

PROCEDURE IMPROVED BOOT ELECTROQUIMICO FOR PRODUCTS OF TOMORROW

The requirements in new products increase quickly. They should be more simple, fast, precise, quiet and safe. To meet these needs we need to have better materials. It is important to not only have new materials, but that it is also necessary to ensure their profitable mechanization.

Electrochemical startup has achieved a considerable improvement in the PEM (electrochemical machining of precision) procedure due to the improvement of the technique of the process and having achieved a totally innovative machine concept.

In deep holes there was a minor taper that through another form, for example by interpolation electrode, can be corrected.

This can be machined contours and filigree in materials of high-performance, with respect for the environment. Probably no other technology offers a range of possibilities like, starting with parts mechanical, electrical, pneumatic and hydraulic in the technique of addresses, regulation in the fields of automotive, space and aeronautics, including medicine technique. To this end it is an important fact and is that the technique of the process has improved considerably. He has been decreasing the working distance between the electrode and the workpiece up to 10 microns to considerably improve the perfection of the footprint.

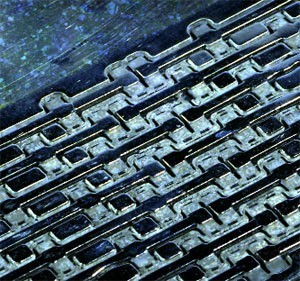

This mechanization by electrochemical penetration leads to other systems in the mechanization of complicated geometric shapes. In addition, the PEM procedure offers the known advantages of the electrochemical machining such as better surface quality, as well as absence of electrode wear and get a working speed more high.

Punch with the PEM procedure

It is possible the execution of structures in miniature in almost all the metals, also in materials of low magnetism, steel of high resistance as well as superallos, which otherwise can not machined or can but with great efforts.

FUNDAMENTALS OF THE PROCEDURE

The list of publications is very extensive. Studies conducted on the PEM procedure in the Institute of machine tools and processes of manufacture of the Technical University of Berlin, and in the Institute of the technique of Microsystems in Fribourg.

The advantages of the PEM procedure can be summarized in a greater accuracy of parts and a considerable higher profitability through a modified electrochemical machining.

It films of turbine of material 1.4914 of dimensions 45 x 7 mm, a distance

between álabes of 1,6 mm and a depth of álabe of 3,2 mm.

Piece of sensor of an alloy with base of nickel, of low magnetism, recocido

final. The material is soft, tenaz, and shows a high behaviour by the

forming in cold. PEM Achieves small structures, conserving

entirely the magnetic properties.

A SMALL THING BUT SMALL

The principles of reduction and integration are taken into account more and more fields. Parts and systems not only must be more compact and thus require less space, but also use less material and energy. The development of the current market with the tendency to go increasingly to smaller, for PEM is an advantage added in the mechanization of microprecisión. The improved working process takes place in two stages:

- Opening of the distance from work (gap): evacuation started materials and conduct of clean electrolyte.

- Closure of the working distance: electrode approaching head-on up to 10 microns. The momentum of current, which is who starts the material, is released.

The advantages of the PEM procedure can be summarized in:

- Process control more precise through a front working distance between the electrode and the part of 10 microns.

- Consequently an improvement of the accuracy of the footprint

- The improvement of the conditions of cleaning

ADVANTAGES IN THE PRACTICE

As a result of the foregoing PEM has brought to market an innovative machining system for mechanization by electrochemical penetration. In principle does not exist or is very small wear and tear on the electrode. 6,000 Pieces of steel for tools with high contents of chromium, with a single electrode can for example be machined. Due to the complex process, the design and implementation of the electrodes is different for EDM. For this reason there is also a cost advantage.

You can install multiple fastening devices, being guaranteed the parallel with the PEM process.

Due to the technical capacity of the PEM procedure, and the uniform conduct of electrolyte flow, speed of work is possible. The boot sequence of material, depending on the type of material, is between 500 and 700 mm per minute, with a step of 0.1 to 0.5 mm per minute.

Deep drilling produces a smaller taper, which in addition, other electrode of form can be corrected.

The Mission of the electrolyte is the conduction of current, the transport of the grubbing-up material and the evacuation of heat.

In our case it is not necessary to take measures of security, because in contrast to the dielectric by penetration EDM machines, our electrolyte is a solution of water salt, respectful with the environment.

The electrolyte produces an effect of oxidation by what the machine is constructed with a basement of granite and execution in stainless steel.

Other advantages of the PEM system are the best surface quality and a much more decorative appearance of the finished piece. There are no alterations in the piece since the process does not produce any influence either thermal or mechanical.

6) METALUNIVERS Abril 2002

Related Companies or Entities

Suntec Maquinaria Técnica, S.L.