Machine Center, S.A. in the EMO 2007

5-Axis vertical machining center

Okuma vertical 5-axis machining centre model Millac-800VH with control OPS - P200M CNC has table type box and a robust surface for travelling. It has large bearings and highly rigid supports, pretensados to ensure stability in precision. Fast displacement of 30 m/min to axis X, and and Z and speed cut of 12,000 mm/min (X, Y, Z), incorporates an integrated 10,000 min-1 spindle (18.5/22 kW) is # 50, high speed, high power and compact design. With variable angle to 0, 001grados, the mechanism of hydraulic mooring can withstand a strong pace of court. In addition, is equipped with a system semi-freno and retrieval system of scale, optimal characteristics for work of 5 simultaneous axes. The rotation of the spindle is 150 ° (30 ° + 90 ° + 30 °) which increases the area of process, and can position the spindle in any of its 150 º drastically reducing court time and allowing the use of portas motorized standard for efficient machining the workpiece.

Incorporates 2APC Rotary type that they reduce the preparation time and increase productivity, being the time of change of pallet of 20 seconds.

Lathe of high precision LB3000 EX MW

The lathes Okuma series LB Space Turn EX (EX LB2000/3000/4000), ruled by the P200L control, which replaces the previous incorporating in its standard configuration before optional specifications. The model LB3000 EX MW, in its version of motorized tool and subhusillo, presents a few quick tours of x:25 z:30 m/min, 22/11 power kW and a turnaround until 5,000 rpm for the main spindle and 11/7, 5kW and a shift of up to 6,000 rpm for the subhusillo. It is equipped with the system Thermo Friendly, to control the thermal deviation, and has a larger size of spindle and a higher speed linked to high precision in machining.

Lathe multitasking

Okuma completes its range of lathes multitasking with the smallest of the series, the Multus B200W model works with dish of 6 "and, optionally, with 8" with a distance between centers (version with or without counterpoint) to 550 mm and 750 mm (version subhusillo). It uses an oversized spindle of 62 mm in diameter and 11 kW, rotating up to 6,000 rpm in its standard configuration. Applications are adapted to any machining. The spindle of milling has engine 11 kW and 12,000 rpm as standard and, optionally, 9kW and 20,000 rpm. Get machining of high precision thanks to the TFC concept which allows control of possible deviations due to the thermal effect. As the rest of the series equipped with control Okuma OSP-P200L with 15-inch LCD and the Anti collision CAS system.

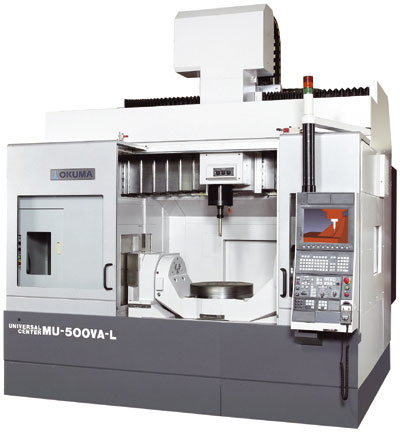

Continuous 5-axis vertical machining center

Okuma also with 5 continuous axes MU500VA-L vertical machining center. This machine includes function of turning, allowing a high precision for the machining of parts for medium and large size (maximum of 730 x 500 in diameter). Designed with the Thermo-Friendly-Concept (TFC) technology, which ensures a heat flux controlled with minimal effect on the thermal deviation of head and structure, this center incorporates the Trunnion table, System DD Okuma, of fast and accurate positioning engine, and function of turning, which produces an intensive machining. This function is equipped with control of Okuma OSP-P200M and system anti-collision, which drastically reduced preparation time, especially for complex machining. As a consequence also decreases the costs per piece and increases machine availability.

Universal CNC lathe

Universal CNC lathe Romi C 420 offers you flexibility of working for multiple applications, with various configurations of dishes and locked. Equipped with control Siemens Sinumerik 802 D SL, for high performance and high reliability hardware, it offers resources for programming and operation with graphic module for simulation of the machining. The bench is supported by columns of cast iron, with internal ribs, which provides great absorption of vibrations during the varied conditions of machining. This, together with the flat and prismatic guides to ensure permanent contact of the Bureau on the bench, make that this machine offers high stiffness, stability and precision in operations at full power.

The machine is equipped with main engine AC of 10 HP (7, 5kW), servo motors and drives Siemens, temperate and rectified the transversal carriage guides, and contraguías coated Turcite.

Up to seven axes multifunction machine

Okuma Multus B400 works with up to seven axes, and manages to machining of high precision thanks to the TFC concept, which allows control of possible deviations due to the thermal effect. Equipped with PC-CNC Okuma OSP-P200 with 15 "and touch panel LCD, is the new protection strength anti-collision CAS. With a capacity of length of turning of approximately 1,500 mm, allows machining medium-sized parts, uses an oversized spindle of 80 mm in diameter and 22 kW, with a twist of up to 3,800 rpm in its standard configuration. The spindle of milling has 14 kW, while the bench and the telescopic are molded in cold, and have a very rigid structure which supports a chip startup ability in turning 4 mm of depth by passing and a capacity of milling end of 450 cm_/m.