This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Un esfuerzo comúnDay Redauto: Strategies of recycling in the car

A joint effort

The Act sparked a remarkable interest among all industrial sectors

There is a park of over 23 million vehicles, of which 35% are vehicles with more than ten years old in Spain: an aging Park which will probably lead to waste to be treated. Table, already in itself worrying, is compounded if you add two more data: only in the year 2000 were of lower 943.000 vehicles and from now, exactly from April of this year, vehicles no longer in use shall be considered as hazardous waste.

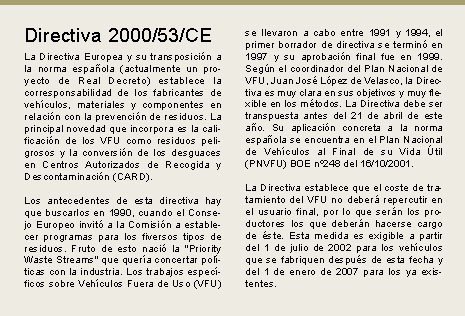

Broadly speaking, this was the preliminary framework of the first days that organized Redauto. Trying to, of course, about "Strategies of recycling in the car", and had the promotion of the Ministry of science and technology. The theme star was, of course, adapting to the Spanish law of the Community rules on recycling of vehicles no longer in use (OUV).

Attendance at the Conference was a success. The room of the Hotel Barceló Sants in Barcelona where took place, was attended by organizations and representatives of companies of all kinds, from institutions dedicated to research in the plastic sector until textile processors, manufacturers of components and "Metalworkers". Any proof that we have 'the industry of the industries', as described by Peter Drucker to the automotive industry in 1946 and that someone dealt with recall during the day. Not in vain: the objectives of recycling requires agreement between all those involved in the life cycle of the car.

The day was divided into three main areas. The first block was dedicated to manufacturers while the first paper reserved the technical adviser of the Sub-Directorate General of environmental quality and coordinator of the National Plan of OUV in the Ministry of environment, Juan José López de Velasco. Followed two industry heavyweights: the head of laboratory of technology of materials (José María del Mazo) SEAT and head of Department of Nissan Motor Iberica and advisory materials and technology of Nissan European Technology Centre Spain(, Oscar Milián).

The second block was devoted to the component manufacturers and suppliers of top level, (Lear Automotive, Idiada Giugiaro and group Antolín). The last block was dedicated to experts and ideas and new business activities generated.

Manufacturer is responsible, not for the costs of treatment, but the cases in which the recycling of vehicles will shed a negative balance

But let's start at the beginning. During this first block the moderator of the talk and representative of ANFAC, Carlos Mataix, wanted to deny a news which had been circulated recently and that came to say that the new legislation makes it compulsory for manufacturers to be responsible for the cost of recycling of the vehicle. Carlos Mataix said that it was a false claim, "the manufacturer takes over, not the costs of treatment, but the cases in which the recycling of vehicles will shed a negative balance". In this connection the Coordinator of the National Plan of OUV, López Velasco, stated that studies show the sale of scrap metal in Spain covers the costs of recycling and that according to the foresight of the sector, "until the year 2006 there will be no negative balances"Therefore, and contrary to what is happening in other European countries, "here we understand that you should not move to the user any increase in price".

Another hot point of the day referred to the scrapyards necessary to do charge of the VFU, that the Administration has enciphered in more than 1.000 (“there is the one who has said that they are too many”— explained López of Velasco—”that was sufficient one by province, although this would not fulfil the community directive that establishes that it is necessary to cover all the territory”). In this appearance, the plan foresees before the year 2003 the creation of a network of until 1.085 centres authorised of reception and decontamination (CARDs).

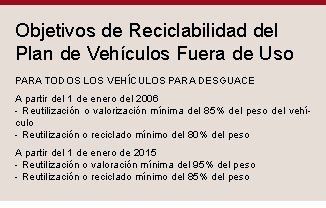

Manufacturers do not see problems to reach the percentage of recycling of the year 2006 (85%) but that there will be problems to reach the rates of 95 per cent by the year 2015

Another interesting aspect is when a vehicle leaves to become a hazardous waste. The Administration has decided that "A vehicle shall be considered waste when the certificate on the CARD is issued", this excludes the abandoned vehicles, for example, although to save this stumbling block the delivery of the vehicle to the CARDs won't be any cost to the user.

Added to this is another problem that the directive has not contemplated and that the representative of Sernauto, José Antonio Jiménez Saceda, wanted to put on the table. Spain generates now 841.000 tons of waste from the repair of the vehicle components during its useful life.

Spain generates now 841.000 tons of waste from the repair of the vehicle components during their lifetime

Towards an integrated policy of consumption

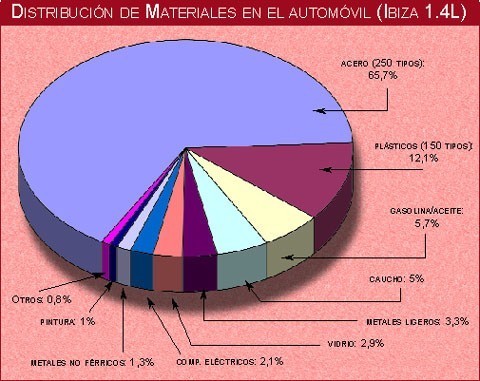

Manufacturers highlighted the contribution made by the representative of Seat and head of laboratory of technology of materials, José María of el Mazo, which called for "a reorientation of European policy towards an integrated policy of consumption". What does it mean? In his talk, responsible for SEAT showed some implicit contradictions of the EU directive on recycling of vehicles and their transposition to the Spanish legislation. These contradictions are obvious if analyzes the life cycle of the vehicle and is valued it globally. The first contradiction concerns the relationship between weight and safety: we must reduce the weight of the vehicle, opting for aluminium, for example, and should increase the safety, condition that requires increase the weight. Therefore, vehicles weighing the same as before although the materials used are lighter.

Another logical contradiction is that exists between more comfort and less consumption, or from emissions to recyclability, for example. In this aspect, SEAT compared to the lifecycle of a car of steel and aluminium. The results speak for themselves: aluminum cars reduce consumption and emissions (the ratio is 10% less consumption by 25% less weight) but its recyclability is only 67%, compared to steel carsmore pollutants, but with a 75% recyclability.

It is this lack of global vision which has given rise to some complaints from manufacturers. Manufacturers are "prepared to meet some requirements" for the representative Seat, although in some areas are not under the directive. An example of what, in his view, it may be nonsense, it is the fact that administrations came them to ask that they build vehicles that lasts longer, "made that he opposes the same Plan Renove".

Even with everything, according to José María del Mazo, manufacturers do not see problems to reach the percentage of recycling of the year 2006 (85%) but that there will be problems to reach the rates of 95 per cent by the year 2015.

"There will be to increase the mass to be recycled by 7%," said del Mazo. The problem is that these manufacturers have also committed themselves to reduce the consumption of the vehicles by 25% in the next 20 years.

A design for recycling

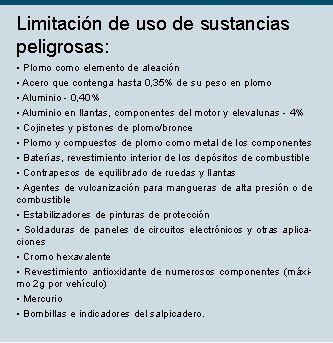

Nissan strategy for the implementation of this directive turned the talk of his representative, Oscar Milián, on the day. This strategy involves designing vehicles for recycling. This means reducing the hazardous substances, increasing the components made with recycled materials (now the percentage is 8%) and marking materials.

The environmental policy of Nissan envisages a reduction in the number of pieces and the number of components, as well as the reduction of the weight of the vehìculo and the use of common materials.

Nissan is expected to have the complete elimination of the substances directive specified as toxic (see table) except in cases in which there are no more alternatives. Another aspect is intended to reduce the use of PVC to a percentage less than 33 per cent in 2005.

Shared responsibility with the manufacturers of components

Designers and suppliers of first level were part of the second block of the day and surprised by their capacity for initiative and development of ecological alternatives adapted to the new directive. Broadly speaking, the conclusion is the need to increase the percentage of recyclability of plastics used in vehicles. Currently, recycling 75% of the weight of the vehicle no longer in use. This fraction, the metal part is 90%.

We must recycle more plastics

Joan Vidal Juncosa, Idiada Giugiaro company, specializing in vehicle engineering projects, considered aspects of recycling in relation to vehicle design. This design should be seen as far away aspects such as ergonomics or aerodynamics, safety, cost requirements and now recycling requirements.

According to Vidal, the problem of recycling of vehicles is not in the metal part of the car (that is recycled without problems) but in plastic materials. I.e., to increase the percentage of recycling should increase the recycling of plastic materials, which tends to grow in automotive applications.

In this sense, Vidal stated that builders are starting a series of actions in regards to these plastic materials.

The Group Antolín, manufacturer of French and components for the passenger compartment, explained in his talk the system used to meet the requirements of quality and environmental (that they have been called index environmental Antolín). According to the representative of the group, the requirements in the environmental section come from builders and concerning the plastic materials used. In this respect, there were complaints about the reluctance of suppliers of second level to provide data for the materials they use.

The group Antolín has llevar some investigations in plastic materials and also in mechanical systems. These investigations look for the replacement of the chromium hexavalente in all the protections and the replacement of heavy metals in metal injected of base cinc.

5) METALUNIVERS March 2002

Related Companies or Entities

Asociación Española de Fabricantes de Automóviles y Camiones

Asociación Española de Fabricantes de Equipos y Componentes de Automoción