Trends in safety helmets required much of the thermoforming process

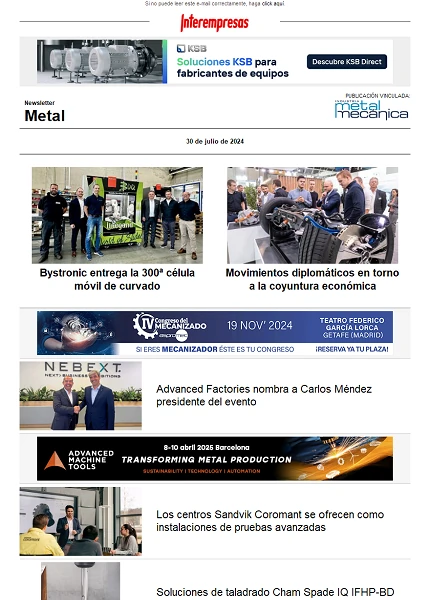

The trend is the cut of plates and pre-serigrafadas to be termoconforman of completely automatically. The line of thermoforming Comi Srl model Helmatic has been studied and perfected just to meet the production requirements.

- Work dimensions: 800 x 600 mm

- Max. processable mold: multiple mold until 4 cavities

- Material to be processed: PC printed in sheets

- Production: more than 100 cycles/h

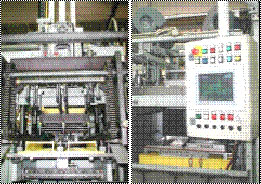

Thermoforming line model Helmatic is composed of:

- a silkscreened prints loading station.

- a group of focused.

- a system of precalefacción sheet.

- a system of transport chains, capable of transferring the blade automatically to each station on the line for thermoforming.

- a final double panel heating system.

- a station of formed with sensor laser focused end.

- a press of the separation of castings.

- a system of automatic stacking of separate helmets.

- collected waste into a specific container.

Also the height of the sheet on bubble phase is controlled automatically.

All this guarantees a high quality, repeatability and reliability of the process.

Another aspect that gives value to the new thermoforming line model Helmatic, is that of heating furnaces, composed of panels equipped with resistors in ceramic of small size, uniquely, controlled to allow excellent control of the thermal profile that you want to give the material.

The line has been also equipped with a system of control of the temperature of the plastic material, to avoid that fluctuations of temperatures caused by external factors may affect the material to be processed with a perfect record in the process of heating plate.

Another aspect which is of great help to the operator is the ability to memorize numerous programs and data of the machine, thanks to a software by Comi specific for this type of product.

The line is completed with a press that allows individually separate the helmets. The product obtained shall be transferred and stacking on the tape of discharge for the external collection by an operator.

The possibility of using "calottes" molded forms and/or different drawings with the only condition to have the same thickness of the material is particularly interesting.

In addition to all that, there is also the possibility of a quick-change system of the mold to facilitate all operations by minimizing the stop of the change of production equipment.

There is also the productivity that can be achieved. In fact, achieved speed is more than 100 cycles/hour in the case of the mould 4 cavities allow a productivity of more than 400 helmets/hour.

This new proposal of Comi wants to be a concrete response to the increasing application of flexibility, speed and quality of work for this type of product.