This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Los productos de CNC de GE Fanuc protegen tanto al personal, como a las máquinasWorking with speed and security

GE Fanuc CNC products protect both personnel and machines

Machine tools have evolved to become more effective and faster machines, and similarly should move security measures installed on them. To achieve this, GE Fanuc has integrated two features in its new generation of CNC products: the function of verification of interference in 3D to prevent collisions and the role of security with double checking to protect the operator.

In recent years, the development experienced by machine tools has resulted in machines of high performance with axial acceleration, sometimes exceeding several times the acceleration due to gravity. The speed of the movement are also very high, that it is more difficult to visually follow the revolving processes, of milling or bore. The complexity of the machines has also increased considerably. As a result, if five or more axes are controlled at the same time, the tool reaches a mobility, as well as numerous advantages, offering also the disadvantage of a high risk of collision at high speed.

Together with the capacity of the machines, the complexity of the components to machine has increased and requirements of staff and programs for the machine have widened significantly. It is here, in which high-tech CNC products can provide great help.

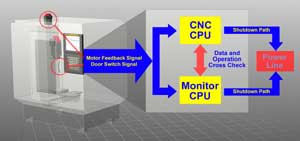

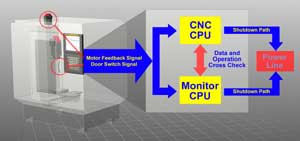

The open workspace is a source of danger: with the role of security with double checking of GE Fanuc, the necessary security doors are connected to two CPUs, and can both verify if they are open or not. If a door is open, the control system switches to a security mode, which allows you to preset movements only in ranges and speeds.

3D interference checking function prevents collisions during the preparatory process

With their CNCs for the Series 30i model A and model A/A5 31i, as well as their corresponding open CNCs 300i and 310i, GE Fanuc, a world leader in CNC products, it offers a system special integrated real time to prevent collisions between the components of the machine and the piece during operations in automatic and manual. This feature, called "Check for interference in 3D", is especially useful during the preparation of the machine, especially if they are to process complex components.

While generally a program already proven is used for automatic machining during production, the danger of collision is significantly increased during the procedure of preparation. The operator of the machine should make implementation underway with different parts using calipers or "explore" the piece to designate the zero point. However, if it's complex tool movements required for this procedure are complicated and not always predictable.

Reliable and innovative

GE Fanuc CNC products are more reliability around the world. This feature is linked to a high degree of innovation, as it can be seen in another large number of important developments, as well as the security features that have been tabled. For the full range of applications, from lathes of basic level up to complex 5-axis machines, new hardware and software products offer higher performance, easier management and improved productivity manufacturers of machines tool and end-users. In addition, essential elements in the range of products from GE Fanuc are the products of drive, between which are linear motors and high-torque technology.

Open CNC products allow visual simulation in real time

In order to avoid collisions, the operator can protect the piece and the devices that hold it through the check for interference in 3D. For this operator must first define the objects that have a risk of collision. This is achieved through the use of surrounding cubic geometry, referred to as areas of interference, which surround the piece and its mechanism of subject. They act as a limit switches software, stopping the movements of the axle immediately after a 'contact'. The elements of the machine (for example, the table) are already defined as areas of interference by the manufacturer of the machine. The interference of the tool, including mooring area, is determined by the control system using the introduced data of length and diameter.

There are two ways of introducing interference for the piece and its mooring areas: for products of standard GE Fanuc CNC, the operator must specify the values of the parameters. Products of open CNC GE Fanuc series 300i and 310i, equipped with an additional industrial PC, offer even better facilities. A library (interface FOCAS2) function allows the operator to program with visual support protected areas and simulation software indicates the movement of the tool in real time. If there is any interference in the protected areas, the machine stops immediately to prevent a collision, both with standard CNC products, and with the open CNC. On the PC, risk areas are displayed as well as intermittent form and color.

With its CNCs for the Series 30i model A and 31i model A/A5, as well as their corresponding products of CNC open 300i and 310i, GE Fanuc, a world leader in CNC products, provides a real-time integrated specialknown as "Check for interference in 3D", which prevents collisions between automatic and manual components of the machine and the piece during operations.

Active safety for staff and machines

The power, mobility and speed of a modern tool machine not only endanger the piece and the machine, they also represent a significant potential risk to the operator. For this reason, machine tool must meet currently with the rules of safety category 3 (EN 954-1) to ensure the safety of the machine and the operator. Instead of using mechanical safety precautions, modern CNC products can deal with this task also.

A special function integrated in products of CNC GE Fanuc, so-called security with double checking, contributes to the security "of active mode". Unlike security mechanisms "liabilities", consisting of mechanical components and electrical trailers, such as protective doors and switches of security, the active mechanisms are integrated in the machine control system. Through sensors CNC monitors access to the machine and all the movements that it runs. Compare rates and current positions of the pieces of the machine (shafts and heads) moving with speed data and position specified in the security settings. These parameters are security protected against unauthorized access. If necessary, and in situations of emergency, the CNC machine.

Through sensors CNC monitors access to the machine and all the movements that it runs. Compare rates and current positions of the pieces of the machine (shafts and heads) moving with speed data and position specified in the parameters of security, which are protected against unauthorized access

Two channels for 100% security

In order to guarantee a 100% safety, the control system must monitor the machine through two channels. This requires two independent processors. However, for GE Fanuc control systems, this does not mean that you have to face additional costs, as they have a CPU of the CNC and a CPU monitoring, they supervise the engines, as well as safety I/o signals. In addition, the CPU of the CNC, the core of the system, provides algorithms and CNC programming techniques. Through separate channels, CPUs are the signals that indicate the status of the machine. Each has its own RAM data and has knowledge of how is the exchange of data from another CPU with motors and amplifiers. In this way, each CPU verified their own data with the of the other processor.

The necessary security doors are connected to two CPUs, and can both verify if they are open or not. If a door is open, the control system switches to a security mode, which allows you to preset movements only in ranges and speeds. In case that current data do not coincide with scheduled data, the CPU activates status of disconnection of emergency, which puts the machine in a neutral position of security as soon as possible.

The advantage of active safety precautions, such as the role of security with double check, is that it can ignore many devices as for ejemplofinales's career, as well as of his wiring and programming. This saves space, errors and work in the closet of maneuver. CNC must, however, control the speed of the engines, so all that has been added are some ancillary tasks of verification by software. This is a savings in costs for the manufacturer of the machine tool, which, in turn, benefits the end user.

If five or more axes are controlled at the same time, the tool reaches a mobility, as well as numerous advantages, offering also the disadvantage of a high risk of collision at high speed. GE Fanuc CNC products protect personnel and machines.

Related Companies or Entities