This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

La sinterización por láser, preparadapara la producciónEOS offers new dimensions that make it possible

The sintering by laser, preparadapara production

Laser sintering saves time and money in the manufacture of prototypes during the development of the product. Recently, this innovative technology has been used for the economic production of small series of pieces of metal or plastic in all phases of the life cycle of the product. The techniques to be considered in this development innovations are, on the one hand, the increase in productivity of the system that includes a degree of automation and integration of the higher process and, on the other hand, the availability of new and optimized materials.

Souvenirs of the Frauenkirche in Dresden Church, thanks to the direct sintering of metal.

High-tech and Baroque

The example of the Frauenkirche in Dresden Church demonstrates impressively how modern technologies, such as the direct sintering of Metal by laser (DMLS), can be useful in the fields of art and architecture. The SFM GmbH company employed innovative technologies to produce an original model of the Frauenkirche, in a short period of time and at reasonable cost. SFM had the idea to sell the models as "souvenirs" to finance the reconstruction of the Church. He chose the molding by injection of Thermofoam as optimal method of production, designed first and foremost a CAD model to scale 1: 500 and generated data from the mold in STL format. EOS (www.eos-gmbh.de) produced then the inserts of mold, very complicated, with DirectTool process, in a system of sintering EOSINT M 250 Xtend laser, material DirectMetal 50. Given that models should present a similar stone surface, the inserts not infiltrated or honed after sintering. The mold is then completed and produced models in collaboration with the moldista Friedrich & Sohn in Crosta and Technoplast Kunststoffverarbeitung in Großröhrsdorf. Due to the high complexity of the geometry of the mold, other manufacturing methods would have required wire EDM, which was deemed too expensive. The DMLS mold continues to use to produce models that are sold as "souvenirs" in different versions, at prices between 30 and 45 EUR. According to the accumulated experience, SFM expects to reach a production of 10,000 pieces with the same mold.

New powders of metal for more precision and details

Recently there has been the powder based on steel DirectSteel 20. It's a new development of tested metal powders optimized for particular applications for direct sintering of Metal by laser (DMLS). With DirectSteel 20 you can work with thick layer of only 20 microns, achieving an optimal resolution of details. The surface quality of parts is sufficient for the injection moulding, unpolished in the majority of cases: only after a quick and simple "micro-shot-peening" (micro blasters with surface compaction by impact). The sintered, impacted surface is similar to the textured surfaces that are conventionally obtained by EDM. If required surfaces polished by technical or aesthetic reasons, they can be achieved without problems. In comparison with previous materials, the significant improvement of surface quality allows considerably juvenile finish times. High density, with the effect of compression of the micro-blasting, allows finishes up polished mirror.

Recent marketing, new dust DirectSteel 20 is already providing results as in the project described below. And for applications that require more quickly, there is also good news:

EOS R & D has developed a new metal dust which will be available very soon. The 20 DirectMetal reaches higher process speeds with the same precision and resolution of details. Therefore, it is an ideal complement to the 20 DirectSteel in applications that do not require a high mechanical resistance, such as the majority of projects of injection moulding.

The CAD to high quality parts in three days

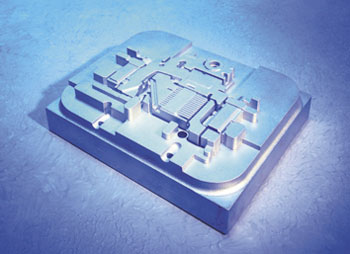

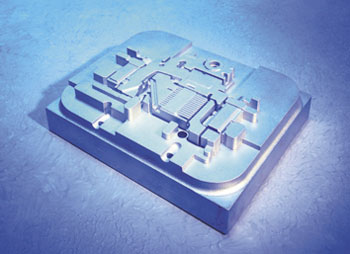

The project of the consortium of manufacturing rapid (Spanish Rapid Manufacturing Consortium), under the direction of Prof. Philip Dickens with the Swedish Automotive Group Volvo Car Corporation, is the manufacture of male and cavity for the molding by injection of an adapter for a vehicle (see photo).

The inserts are approximately 60 mm in diameter and 22 m in height, with interior angles of 90 °, what not to allow the machining, but that you would normally use EDM. In this case, the inserts are produced with the new material DirectSteel 20, extremely fine, in a fully automatic process with a system EOSINT M 250 Xtend. Through a three-dimensional machine, measured six dimensions in each of the inserts, appreciating an average deviation of only 0.032 mm, with a maximum of just 0,068.

In this way, were injection moulded parts of high quality in only three days since the availability of data in 3D CAD.

Surface finish of DMLS parts

In addition to systems and peripherals of high level for sintering by laser, optimized EOS solutions also include consulting for optimal integration in existing processes. In manufacture of moulds, adjusting and polishing of the mold components are an integral part of the process chain, and therefore, also the DirectTool process. EOS has established a base of knowledge, systematized on this subject and has devoted a specific seminar at the international meeting of users (IUM for International Users Meeting) of this year.

It has been shown that micro-blasting not only provides excellent surfaces in a quick and simple way, but is also a very important step for subsequent processes of sanding or polishing of non-porous surfaces. It has been that virtually any surface quality can be achieved with the use of equipment of ultrasonic and diamond pastes, (see photo of insert mold blasting and polishing).

The EOSINT P 380 new can make parts of PA or PS, as this functional prototype of vacuum cleaner.

DMLS - the result of a collaboration with success

The current success of the direct Metal laser sintering is the result of a long-term collaboration. It began in 1994 with a contact between the Finnish company Electrolux Rapid Development and EOS GmbH. Electrolux was one of the first European companies to implement rapid prototyping and it had already developed a metal powder of low shrinkage for sintering without pressure. EOS had developed and marketed a dust of plastic for sintering by laser. Both companies asked how to combine the respective developments. After some early encouraging tests, they established a cooperation agreement and a year later developed and installed the first system of direct Metal laser sintering in Electrolux. In 1995, was presented the system EOSINT M 250 as a series product. The first material was a metal powder based on bronze capable of manufacturing parts and inserts of mold in layers of 100 microns. The technology has settled in a short period of time as a fast and precise process of rapid manufacturing of moulds (rapid tooling).

The close cooperation between the two companies led to the development of a more fine dust, for layers of 50 microns. The first powder based on steel, along with a new generation system was introduced in 1999: EOSINT M 250 Xtend. Recent fine grain powders are a step forward and a significant milestone towards the rapid manufacturing (Rapid Manufacturing). Currently, DMLS is a well established process, with more than 65 EOSINT M systems installed in 15 countries. DMLS development of the previous Electrolux Rapid Development team, has been integrated to the EOS Group as a subsidiary to 100%: EOS Finland. Electrolux Rapid Development services sector receives the name of Rapid Product Innovation and today forms part of the Alphaform group. And the cooperation continues.

The system of sintering of metal by laser EOSINT M 250 Xtend.

DMLS convinces the moldistas in Spain

With the acquisition of the EOSINT M 250 Xtend system of last generation, BMP, the new Division of prototyping of the rusts group in Barcelona, strengthens its position as the Group r & d Department. Founded in 1963, the rust group is a leading company in manufacturing moulds.

Although it has just started its activities, ProtoSer, the new distributor of EOS in Spain and Portugal situated in Cabrils, near Barcelona, you can already announce the sale of this first system, which has now concluded thanks also to the excellent preparation by EOS France.

Plastic laser sintering

For plastic laser sintering, EOS also offers new dimensions for a high degree of automation and integration of the process, basis for the rapid manufacturing (rapid manufacturing). With the system EOSINT P 380, available from the first quarter of 2002, EOS presents the latest generation of the renowned EOSINT P 3 series of systems with a laser only. Several new features of hardware and software are able to increase productivity by more than 30 per cent at the same time to improve the quality of the parts. The integrated process of work (IPCM, by Integrated Process Chain Management), with automatic feeding of powder and a new station of recovery, provides a high degree of automation and ease of use. Both the system and peripherals are well prepared for integration into industrial, being particularly suitable for rapid manufacturing environments. And once again, all of the new features are available as enhancements (upgrades). The pioneers of the first systems can streamline their "old and good P" until the last State of the art.

The system of sintering of metal Eosint M 250 Xtend allows direct sintering of powder of steel and the creation in hours of moulds for up to 100,000 injected parts.

EOSPACE: New software for data preparation

To offer the highest levels of automation and flexibility also in the preparation of data, EOS has exclusive of a new software package from the first quarter of 2002. EOSPACE of "nested" automatic software based on surface, positions the pieces in the volume of construction fully automatically, optimizing the use of the volume unless the pieces touch or are linked and, therefore, reducing the height of the building to the minimum necessary for larger piece. This allows to save time and costs of process, and to avoid errors.

Related Companies or Entities

EOS GmbH - Electro Optical Systems