Este artículo fue escrito originalmente en Spanish. Se ha traducido automáticamente para su comodidad. Se han hecho esfuerzos razonables para proporcionar una traducción precisa; sin embargo, ninguna traducción automática es perfecta, ni es su intención la de sustituir a un traductor humano. El artículo original en Spanish puede verlo en

La máquina del futuro podrá atender necesidades muy diferentesExamples of variable machine tools were presented at the EMO exhibition

The machine of the future can meet different needs

The modular configuration of the machine tool promises a number of advantages: on the one hand, the machines can be designed for finishing even complex parts and, on the other hand, the concepts have become so versatile that allow that a machine can be reconfigured to carry out new tasks when the modules are exchanged. The conferences based on "Modularization" at the symposium which took place at the EMO exhibition presented some examples of these machines - variable tool from three practice-oriented research projects.

Dominic Deutges of Monforts: "We want to make possible the complete machining of components axisimétricos". "This shortens the process chain, saves time and improves the accuracy of manufactured components"

Markus Stanik of Ex-Cell-O: "the important thing is that flexibility in processes and technology, not only in the machine there is also". "This means that technological changes are also possible, for example, the replacement of a method of manufacturing on the other".

At the Symposium "Machine tool of high performance for the production of tomorrow", organised by the Federal Ministry of education and research and the German Association of machine tool, VDW, was announced a series of projects sponsored by BMBF. Presented a thematic field under the title "Modularization" who picked up three projects titled LoeWe, Meteor and KombiMasch supervised by the Division of technologies of production and manufacturing (PFT) of the Karlsruhe PTKA Research Center. These projects had investigated the modular machine tool and standardized interfaces over the last 18 months.

Made sure the practical nature of the day thanks to the participation of companies that incorporated the results directly into their products after providing "know-how" to each project.

These three projects have left in different directions to reach the flexible machine tools. In this way, various technologies for machining, quality assurance, and documentation allows the integration in one only machine as required, a flexibility that will lead ultimately to reductions in the cost of the life cycle.

Turning, milling and machining complete laser on a single machine

The development of the interdisciplinary project KombiMasch is a combined machine tool that facilitates more than one method of machining. It should dominate the turning and milling soft conventional, as well as the hardening and coating by laser and the turning hard. Dominic Deutges, responsible for design of a. Monforts in Mönchengladbach, coordinates this project. The advantages of these machines ahead of them: "We want to make possible a complete machining of components axisimétricos". This shortens the process chain, saves tooling times and increases the accuracy of the manufactured components".

Machine tools available on the market are mostly specialized in a single method of manufacture. However, customers are demanding a greater variety of more complex components, which is why the companies for the most part, have no choice but which provide variants of machines - tool, with high investment and maintenance costs attendant. Components are sent from a station of machining to the next and even perhaps to special treatments such as tightening external facilities. The declining work of lower dimension often mean that these expensive machines are not operating at its full capacity. Investments on multiple machines, the extensive logistical work and multiple processes of tooling harm economic efficiency.

Methods of machining can be combined by the user

KombiMasch is aimed at the development of a machine that can be built for individual needs from a kit of construction of standardized modules. This needs competitive partners in the field of the manufacture of machines, laser technology, sensor technologies, development of CAD/CAM, and technology applications and processes. Together working on the integration of individual machining units that can be put together for the complete mechanization of specific products.

The completion of projects KombiMasch will show a machining center based on a lathe which can also drilling and milling and allows hardening and coating by laser of heavy parts.

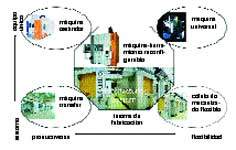

A machine-tool reconfigurable is a machine-tool of universal application which, in turn, can be optimized for different operations. It can be used both as a separate machine and machine specific purpose in a manner similar to agile manufacturing systems.

The Meteor project unifies the advantages of series machines, universal

Institutes and companies participating in the Meteor project work in a "machine tool reconfigurable oriented to the multitecnología". I.e., they want to combine the advantages of the current universal machines and the strengths of the machines of series, and be significantly more economical in his lifetime of service. While universal machines can be used for different applications, they are expensive products because they integrate technologies and machining options regardless of whether they are necessary or not.

Ex-Cell-O works in a machine-tool reconfigurable which is undergoing constant development.

In you told, the machines of series often cost less but are designed for specific applications. Taking into account the life cycles are becoming shorter these machines have always been the first candidates for the progressive elimination: is it worthwhile to devote the time and cost needed to modify them to produce new pieces.

Of course there are possible solutions to the flexible machines-tool design, as Markus Stanik, Chief Designer of special machine in Ex-Cell-O in Eislingen and Meteor project coordinator, explained: "these solutions are restricted only to partial aspects", for example tool and flexible clamps, capacity for rapid change of tools, and fast adjustments to NC programs. We have chosen interdisciplinary development that takes into account all aspects of reconfiguration and should culminate in a global optimum for Meteor. What is important is that there are processes and flexible technologies, not only flexibility in machines. "This means that changes in technology are also possible, for example, the replacement of a method of manufacturing on the other".

"Plug & produce" principle for the rapid retooling and low cost

The machine tool reconfigurable is following the following trajectory to meet these requirements: similar to a machine series, users should be made only with the configuration of machine needed to their real needs of production. But this reconfigurable machine retains its flexibility: the basic design of the machine incorporates interfaces that allow other types of production adjustments at any time. This can be done in a very short time, directly in the workshop and without major modifications which can force even to return the machine to the manufacturer. As a result, users to buy the basic version do not have to invest any money in the flexibility for the future. The large number of modules available reconfigurations ensure, however, a need for flexibility for upcoming tasks.

The basic concept of the machine tool reconfigurable should integrate all important technology modules. These include turning soft and hard, grinding, hardening by laser, welding, jointing, cleaning, drying, baking and elements of quality checking.

LoeWe research project, greater transparency with respect for the life cycle costs

A weak point associated with the current tool machines affects the calculation of costs and economic efficiency throughout the service life. In many cases, only the purchase prices are considered: the technical properties of the machine are not determined in detail, and even the State of the components and their maintenance and repair are not included in the calculation of economic efficiency. So far, these calculations could provide users transparent operating costs already at the stage of granting.

Michael Kirchhoff, head of development at Gildemeister Drehmaschinen in Bielefeld, is coordinating the LoeWe research project. He explained: "our clients and we recognize that increasingly, a machine-tool must end throughout its life cycle." Its components are not infinitely usable, and there are measures of maintenance, etc. "This gives rise to the question about what how much is a machine-tool it really over a period of five to ten years".

This is precisely the point of departure for the LoeWe project. Although in general the objective is to reduce the cost of the life cycle of a machine tool through the adaptation of the modular design of the machine to manufacture new tasks, in detail the modular and adaptive machine tool should provide also information on the status of the machine and its components to the system of monitoring of the life cycle.

Cutting and laser hardening is supplemented by the Court in the development of KombiMasch.

Sensors and actuators to maximize predictive maintenance and repair

Companies and institutes involved in this project are working on a monitor of life cycle that is manufactured with an integrated sensor and smart components. This monitor aims to maximize the use of the operation of machine tools to safeguard their availability and to represent the current costs of operation at all times. This requires strategies and systems of hardware and software that can detect, process and store relating to the life cycle properties of cost efficiency. In addition, the project aims to develop a software system that can calculate and extrapolate relating to life-cycle costs during development, implementation, use, maintenance and disposition of machine tools. This allows to determine and predict the efficiency of Adaptive machine tools throughout the life cycle, providing, for example, users of machines real costs of operation transparent when they buy the machine.

Projects in the field of modularization and participating companies:

KombiMasch

• A. Monforts GmbH & Co, Mönchengladbach

• Precitec Optronik GmbH, Rodgau

• Fraunhofer Institut für Produktionstechnologie (IPT), Aachen

• Laserline Ges. (f) Entwicklung u. Vertrieb von Diodenlasern mbH, Mülheim-Kärlich

• Exapt Systemtechnik GmbH, Aachen

• Sempell AG, Korschenbroich

Meteor

• Ex-Cell-O GmbH, Eislingen

• Schuster Präzision Werkzeug-Maschinenbau GmbH, Denklingen

• Mapal Fabrik für Präzisionswerkzeuge Dr. Kress KG, Aalen

• Ott-Jakob GmbH & Co. Spanntechnik KG, Lengenwang

• Gesellschaft für Fertigungstechnik und Entwicklung e. V., Schmalkalden

• Technische Universität Darmstadt - PTW, Darmstadt

• Diamant-Gesellschaft Tesch GmbH, Ludwigsburg

• Felsomat GmbH & Co. KG, Königsbach-Stein

• Blum-Novotest GmbH, Ravensburg

• Röhm GmbH Sontheim

LoeWe

• Gildemeister Drehmaschinen GmbH, Bielefeld

• Universität Hannover (IFW), Garbsen

• Siemens AG, Erlangen

• A. Mannesmann Maschinenfabrik GmbH & Co. KG, Remscheid

• Ingenieurbüro Dr. Noske, Bielefeld

• Berg & Co. GmbH, Bielefeld

• Artis Gesellschaft für angewandte Messtechnik mbH, Bispingen-Behringen

• Franz Kessler GmbH, Bad Buchau

Related Companies or Entities

Siemens, S.A. - Smart Infrastructure