Promoted by the current

The director of the Area of Customers, Tim Fabian, indicates: “a stream of water is not what resembles simple sight. The only form to keep on being competitive in this sector is to invest significantly in I + D. This is the only form to keep the position like the most important provider of the world”. In the actuality, Flow supplies systems to the aerospace industry, car, mechanical, papelera, alimentary, to the sector of the art and the architecture, of the industrial cleaning and manufacturing of surfaces, and to the markets of processed of foods of more than 60 countries.

“Have chosen to

Under pressesure

The technology of cut by stream of water is one of the processes of machine-tool of faster growth of the world. The manufacturers Are darse that they can attain a greater efficiency and productivity by means of the implementation of streams of water of ultra high pressesure (UAP) in his operations. These streams can cut practically any material, are generally easy to use and keep, and do not produce any zone affected by the heat (DO) that it could distort the material, unlike a lot of other methods of cutting.

The technology of stream of water uses a bomb of high pressesure to convert the water of the tap in a current of water of ultra high pressesure, that flows through tubes and pipes to the cabezal of cutting. The streams of pure water only use water to pressesure to cut the material and are the most adapted for articles such like foods, rubber and foam. Also they exist the streams of abrasive water in which it mixes an abrasive granulated (generally silicate of aluminium) in the current of water before it reach the cabezal of cut, which allows to cut practically any type of material. Although the process of cut by stream of water is quite simple, the materials, the technology and the design applied to the machines of cut is in reality quite complex.

In 2010, when Flow darse that his systems of control were preventing that the company advanced technologically, as it had done it during the last years, decided to invite to a group selecto of actors of the industry to present an alternative solution to remedy the problem. After an exhaustive process of selection, Flow determined that the solution of PC of B&R Industrial Automation was the one who better worked, and converted to the company in his new provider of PC/automatons.

Four faster times that the speed of the sound

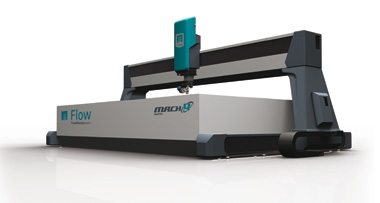

Flow Associated with B&R for the development of his systems of stream of water Mach 2c and Mach 4c. The greater innovation of Flow International, the Mach 4c, implements in his design products of technology totally vanguardista. The system has pumps HyperJet®, that allow to the machine keep until 87 000 psi of pressesure of continuous work while the water travels to four times the speed of the sound. The stream of water also integrates Dynamic XD for bevel-edged cuttings and in 3D, that allow to cut practically any form with precision and rapidity. At present, Mach 4c is the machine of stream of water more exact and easy to use of all the world.

Mach 4c executes the operating system in real time of B&R, Automation Runtime, and includes a core CNC. By means of the use of the tool of development of software of B&R, Automation Studio, the control, the visualisation, the movement, the hygiene and the functionality CNC execute in an alone platform. The customers of Flow benefit of the easy software to use that it adapts to practically all the sizes, forms and types of material. “During the manufacture of the model Mach 4c, took into account the needs of the operarios that work in workshops with high productivity to guarantee to the owner a fast return of the investment”, explains Fabián.

Since Automation Studio accepts reusable codes, the efforts of design of software have reduced to the minimum, and now Flow can centre in the modelling of currents and other innovations of software. “The tool of development of software modulate of B&R, Automation Studio, has been very useful for our personnel of engineering and support”, adds Fabián.

For the visualisation and the control of Mach 4c, Flow opted by a personalised version of the Signpost PC 800 of B&R. Thanks to his robust design without fan were able to attain a high degree of environingingmental protection in the challenging surroundings of this sector. The customers experience a greater performance in an interface of simple and intuitive user: the HMI of Mach 4c. The signpost of the Mach 4c includes until two slots PCI and PCI Expresses, servoaccionamientos modular, additional interfaces and a SAI integrated . The appearance of the signpost is totally personalizable with buttons and pulsadores LED that can program for a big variety of configurations. Besides, the keys of membrane with function personalizable offer multiple options for distinct configurations of the machine. The panels of the Mach 4c are installed on a car giratorio, so that the user can move the screen and control the machine from the point in which it was him more useful.

An alone controller processor includes so much the functionality CNC like PLC perfectly synchronised in the system, allowing a better integration with the platform of control of movement and servoaccionamiento Acopos of B&R. Mach 4c uses servomovimiento together with an automaton of hygiene with And/S that guarantee safe enclosures without need to detain the machine neither the process of production. The intelligent integrated technology allows time of fast answer.

Mach 4c communicates mainly through Powerlink, that links the PC with the servoaccionamientos and motors, the And/S of the machine and the integrated hygiene. Thanks to the architecture decentralised, requires very little wiring. Besides, the flexible design of Powerlink allows to the operarios of the machine centre in his main tasks, without losing time in the technology of bus of field. A speed of transmission of 100 Mbit/s and a precision of synchronisation of +/- 100 ns allow to combine in an alone network even the most demanding tasks of CNC and control of movement. Powerlink Also allows to use devices of third in the same network. The open architecture has allowed to Mach 4c adapt to the needs of the customers and integrate a wide variety of options. Mach 4c is a product referent in the industry. “Our more innovative products include the technology of B&R”, remarks Fabián.