Machining

Development of a system of microfresado for components and moulding supplies employees in Microsystems for Microfluidics

JJ. Márquez Sevillano, J.M. Pérez García, j. twisty rivers, a. Vizán Idoipe

ETSI Industriales de Madrid c/Jose Gutierrez Abascal, 2 28006 MadridTel.: 913363123, e-mail: jmarquez@dimf.etsii.upm.es

01/12/2002 1. Introduction

Micromecánica manufacturing engineering deals with processes based on emerging technologies such as the microfresado (Micromilling) [1], microelectroerosion (MicroElectroDischargeMachining) and micro-machining by laser (Laser Micromachining) for the realization of prototypes of microcomponentes used in the development of Microsystems, about not siliceous materialsbasically metallic and polymeric. And as a technology base for the development of tools of moulding in other also emerging technologies oriented towards mass parts in polymer production such as the moulding by microinjection (Microinjection Molding) [2] and forming in hot (Hot Embossing) [3]. The common denominator of these technologies is the use of numerically controlled with very high precision of positioning machines that allow work on the materials cited with details less than 1µm. The great flexibility of the systems of automatic positioning used, allows the manufacturing of variety of geometries at a very low cost comparatively to the of other manufacturing technologies employed in Microsystems.

2 Experimental

The Group's manufacturing engineering has developed the system shown in the figure to carry out the operations of microfresado. The table reflects the fundamental characteristics of the developed equipment.

3. Results and discussion

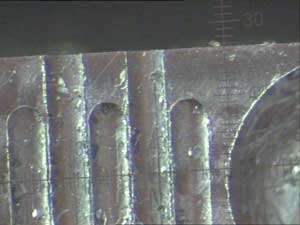

In the Se figure reflected the type of work done in the microfresado tests carried out.

4 Conclusions

An experimental system of microfresado has been developed to develop prototypes of components not siliceous (metallic and polymeric) for employees in fluidic Microsystems. The system has proved effective also in the manufacture of molds for use in replica in polymer Microtechnologies.

Figure slots of 500 µm with 50 µm wall thickness

5 References

[1] Manufacturing of Microstructure surfaces using ultraprecision turning, milling and shopping. Weck M. et to the. Proceedings of the 1ST International EUSPEN conference 1999.

[2] Manufacturing of micro parts by micro molding techniques. Viotter et to the. Proceedings of the 1ST International EUSPEN conference 1999.

[3] Hot embossing as a method for the fabrication of polymer high aspect ratio structures Becker, H. Heim, u. Sensors and Actuators 83 2000 130-135

Related Companies or Entities

Meeting y Salones, S.A.U. - Salón Internacional de la Logística