This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Euromold logró incrementar la superficie de exposiciónEuromold was able to increase the exhibition area

Ibon Linazisoro01/12/2002

The concept "from design, through the prototype to series production" remains a successful phenomenon that, year after year, brings together the industry in the fairground of Frankfurt. On this occasion, from 4 to 7 December, Euromold was held for the first time at the same time with the Turntec fair, aimed at turning. A growing number of exhibitors and visitors than the validity of the Euromold concept which, by the way, already has date for 2003: 3 to 6 December.

The concept of Euromold accommodates all those involved in the development and manufacture of a product

EOS resubmitted news on your stand

The character of Euromold, which brings together in a same place many links in the chain of production, is probably unique, at least in Europe, even more so with the addition of the Turntec fair fair of turning held simultaneously and in the same exhibition. For some the concept is not very clear. The name of the fair seems to refer to molds, but in recent years the fair has been doing honor to its motto "from design, through the prototype to series production" and has been hosting a variety of companies that a priori may not be related. But the truth is that the results give reason to the organizers and are removed it to those who criticize for lack of a concept clear. In this latest edition, the number of visitors was again very successful and reached the 52.840, against the previous edition 51.400. There was no more than look at the corridors on the first day of trade fair to understand that, it is certainly a fair that attracts many companies. Irumold, the moldista located in Pamplona which has been a regular Exhibitor in the fair, was a good example of this. Already the first day received a significant number of professionals interested in their products and activities in your stand did not stop practically in all that first day, and the rest of the fair.

Increasingly are more injectors in Euromold. In this case, a Demag in the booth of Fraunhofer.

The experience was probably similar to the 1,510 Euromold exhibitors from 39 different countries, who presented their products in fields such as the construction of moulds, the development of product, design, rapid prototyping or rapid tooling processes, but also for the CAD/CAMmilling, metrology, laser techniques, new materials... If we compare these 1,510 exhibitors with the 270 of 1994, first edition of the fair, her success there is no doubt. Also over the last year increased the number of exhibitors, in particular in 68 companies, and the exhibition area that has reached the 73.200 square meters.

It was as if the Euromold wanted to demonstrate that the economic situation is not so bad as in some forums see. The number of projects is important, so many exhibitors confirmed, but it is also true that prudence when it comes to investment is affecting many.

Another interesting, not so much by the trend to which points, and its volume is the decrease in the percentage of Germany from companies with regard to the alien. After Germany the main exhibitor country is Italy, 22.1 per cent of the exhibitors, followed by France (8.5%), Taiwan (6.6%), Portugal (5.9%) and others until you reach the tenth top of Spain, with 4.1%.

30.5% Of the exhibitors belonged to the construction of molds and tooling industry. Very behind, in second place, the sector of modeling and realization of prototypes, with 12%, rapid prototyping and rapid tooling with 9.5%, machine tool (8%), soft and hardware (7.6%), engineering (7.5%) and others as tools, design, materials, equipment control or finish.

For Turntec, volumes since then did not reach these numbers. Visited 6.420 people, of whom 8% were foreigners. The picture in this room was not very encouraging, but must take into account that it was the first edition. If Demat, organizer of Euromold, the same rates of increase in this fair to those who succeeded in a few years for Euromold, within a few years we will be without doubt before a great fair.

If we compare these 1,510 exhibitors with the 270 of 1994, first edition of the fair, her success there is no doubt

It was as if the Euromold wanted to demonstrate that the economic situation is not so bad as in some forums see

Husky introduced new models of their mouthpieces for Ultra Hot channels.

FEAMM grouped some Spanish

In a collective stand FEAMM grouped in 120 square meters to several Spanish and supplier moldistas as Cumsa, the standard mould specialist who took advantage of the fair to promote its significant functional and effective, features slides on the set of slideswhich is temperate, rectified and completely indexed. They also stressed in his stand other products such as the new solutions developed for expulsion that allow, since the replacement of an ejector of the mold without dismantling the machine, until the anti-corrosion of small negatives without other mechanisms than the own expulsion. Its modular components for the cooling of the mold, the retentive Auto for large slides and valves of filter, were also the subject of extensive consultations.

Molmasa, Vert and Ochoa industries completed the stand of FEAMM Federation.

As usual, other Spanish moldistas decided to go individually. This was the case of Irumold, Mecanoplástica, Hispamoldes, Tromosa or Marés. Bermaq, Coproin, Laip industries, machinery CME and Epsa, this last company in the stand of its German partner Hoffmann were also present.

Featured products

Soraluce presented at the fair model of TA A 20 milling machine table fixed. Soraluce TA 20 machines have the peculiarity of bringing together on a single machine a more than acceptable power and reduced dimensions. With this model, this company wants to offers an affordable option for small contractors and manufacturers of molds and dies of small dimensions. It uses a CNC Heindehain TNC 426 M Digital. The Danobat group as a whole was present through Danobat Bimatec.

abb I-R promoted at the fair systems of milling supported by a robot for three-dimensional cutting of parts in the automotive industry.

Renishaw introduced several new features. Among them, the transducer of far to scan model SP25M, which stands out for being very compact and very versatile. With the addition of the Renscan technology and a very high flexibility, scanning yields are optimal to using elements of measure by conventional coordinates, as well as instruments for measuring optical. The high number of measurement applications on a machine of measure for coordinates also requires a versatile measuring system. A single sensor with probe is not enough in most cases. The modularity of the SP25M makes it possible to install adjusted to scan modules and probes applications.

Mazak, represented in Spain by Intermaher, presented a machine which caught the attention of many visitors: the Mold Maker Super 2500, intended for the construction of moulds. Its extreme rigidity, system of progress very sensitive to the demands of the current manufacturing, operational accuracy and a software standard designed for speeds of progress and high precision.

Fidia exhibited at Euromold model K197, a Centre for milling 5 axes and high speed, a perfect synthesis of two products of the well-known series K: the K211 and the K165. The new machine offers the possibility of incorporating the birrotativo head of the K211 model, with a performance of spindle 27kW, on a machine with small tours of process (X 1650, and 750, Z 700). All this to achieve very high yields of jointing. Another novelty refers to the center of milling DL155, speed and Acceleration with an extremely high precision dynamic. With a 17 kW and 30,000 rpm spindle, has the following routes: X 1000, and 550 and 500 mm Z

It is an ideal machine for molds and models temperate, pieces of lightweight aluminum and electrodes. Although not as a novelty, the improvements that had set up the HS644 Centre, with a higher performance spindle were also interesting. Surprisingly, Fidia controls were also exposed at the fair.

Brown & Sharpe DEA presented their machines of measure for coordinates of high-speed and high-performance Global model, offering the possibility of measuring shapes, dimensions and position on a single machine. These versatile machines can be equipped with different types of probes in order to carry out a wide range of measures and inspection functions. The new Global line, with their new models 15.xx.14 and 20.xx.15 now covers a range of measurement of X = 500 mm, and = 400 mm, Z = 500 mm, x = 2. 000, Y = 4. 000, Z = 1. 500. Also this company introduced a new system of scanning non-contact for her own line of coordinate measuring machines. Includes advanced measuring sensors that combine elements of optical technologies and laser, as well as software for imaging, in devices that can scan quickly complex shapes and surfaces, and dimensional data acquisition with precision.

CME (Machinery CME) attended the fair with a fixed table of high-speed milling machine model 200 Quick. Its strengths are the high acceleration of 2,5 m/s2 and the exact tracking of the profile of the piece at high speeds, reaching up to 30 m/min. The speed of the head of up to 18,000 rpm always maintains a large pair of 124 Nm (S1), which allows to optimize the machining without maintenance times

EOS (www.eos.info), represented in Spain by Protoser (Tel. 93 790 28 31. www.protoser.com) keep moving forward in the field of the sintered. He introduced at the fair the concept of e-manufacturing, i.e., the rapid, flexible and cost-effective production of high quality products directly from electronic data. He showed this machine Eosint P 700 with IPCM (Integrated Process Chain Management), which incorporates and combines an automatic feeding system of dust, a station of unpacking and a device for recycling of dust. Eospace software, which makes it possible the positioned automatic of parts based on its surface to optimize the process it is for the preparation of the data. Thanks to a better control of the temperature, the Eosint P 700 provides superior surface qualities. Other innovations in this stand were the Prime Cast 100 material for smelting vacuum from sintered by laser models. It is a material based on polystyrene expressly designed for the sinter in Eosint P, allowing the rapid manufacturing of models for function by vacuum. He also presented his DirectTool technology for inserts for small series.

After Germany the main exhibitor country is Italy, 22.1 per cent of the exhibitors

One of the most relevant news in the Eos booth was its co-operation with Trumpf (www.trumpf.com) for the exchange of licences, carried out in summer, and which has already begun to develop. Both are developing jointly a system of production through fusion laser for metal parts directly. It is a variant of the sintered by laser direct metal of Eos, in which a metal powder without binders or fluidizantes melts completely through a laser beam to generate three-dimensional objects with properties as the original material. The process gives the possibility of producing parts of virtually any complexity. The new technology that develops along with Trumpf is a step in the field of rapid manufacturing and rapid manufacturing. The new method is based on developments carried out by

the Fraunhofer Institute for Laser Technology (Aachen, Germany), that it will remain involved in the developments from Trumpf and Eos.

In fact, the cited Institute (www.rapidprototyping.fhg.de) also had a stand at Euromold, where demonstrated their knowledge in numerous technologies to accelerate a process of production. They were curious information on how to make implants dental or artificial bone fusion with laser, the technology that works with Eos and Trumpf. Is manufacturing implants directly from the tomográficos data from the computer, to go, layer to layer, creating a piece

At the stand of Stratasys (represented in Spain by Ilarak - www.ilarak.com) was promoted the machine Dimension, designed for functional 3D printing. It features the notable reduction in price with respect to other 3D printers, so it can pay off quickly. Allow the verification of forms, installation and functionality, with prototypes of ABS and only by pressing the 'print' button.

Dimension of Stratasys, designed for functional 3D printing.

Standex (Tel. 93 336 70 62) showed what you can do with their technologies of textured, with a renewed image highlighting the aesthetics of the final products. Its broad spectrum of possibilities ranges from the structuring of various films (PP, PE, PVC, TPO and ASA), to ABS plates for fields as the thermoforming sector of the car or the manufacture of suitcases and shower cabins. His wide knowledge allows you to make fascinating surface structures in fields such as film for packaging and packaging or others for the field of medicine and hygiene, and even the manufacture of furniture. His new laser technology opens up further new opportunities in industrial, offering textured high resolution even in temperate steels.

At the same stand, he could see how it worked a very interesting machine, the concept laser gmbh represented in Spain by ProtoMold (Tel. 93 759 73 75) and also integrated into this group. Its main feature is the integration of three technologies of laser - marking, erosion and 'cusing' - in a single team and thanks to its modular concept. In fact, Concept Laser was founded in 2000 with the aim of improving the existing technologies of selective laser sintering. The result is the M3 Linear machine, unique in the world and which already has his patent. Of its three functions/modules, laser marking and erosion are probably more known, but not so much the laser cusing, which refers to the production of parts of a single component from metal powder. Final products in steel, inserts casts of series or prototypes can be achieved by this team.

Hermle exposes a new machining center

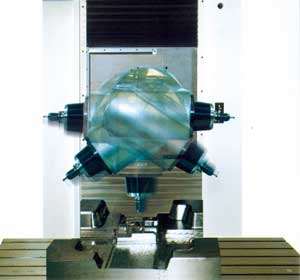

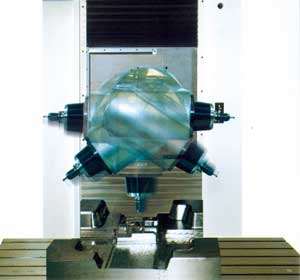

Hermle, represented in Spain by Delteco, presented numerous machines at the fair. The main novelty is the machining center for 5-axis C 40, with construction of trestle type modified, bench multifunctional, made of mineral casting, modular configuration of the variants of table and enlargement, compact construction / full transportation, great freedom of movement in the workspace, high-accuracy positioning and duration, version modular with automation, handling systems etc.

If you look at the drive and guides can point out to the car and is hosted as a crossbar in 3 cars on 3 staggered guides. Ensures good behaviour guide the crossbar through support in three points and central drive. Spindle of progress and the system of measurement of tours is located adjacent to the central car. Also include the roller guides, with Rails outlined in all linear axes that allow constant dynamic conditions.

It highlights the modular construction of the machine, which allows their use for many types of application. This refers, among others, the modularity in variants of the Bureau, as well as the various pylons of pieces in different variants of tables, such as 50 Sk, HSK 100, slots in T, fastening at the point of origin systemspalletizations and many types of media supplies.

Moldistas and European millwrights to discuss the current situation of the sector

ISTMA-Europe, whose Secretary is exercised by the ASCAMM Association that brings together more than 200 Catalan companies and is headquartered in the Parc Tecnològic del Vallès, organized a busy and interesting working dinner involving moldistas, millwrights, and representatives of national associations in 10 countriestaking advantage of his presence in Euromold.

The objective was to discuss the current situation of the sector which, in good part of the traditional producers of moulds and dies, is characterized by an increase in foreign competition and a decrease of domestic demand with the aggravating circumstance, in some cases, an increase in costs.

These circumstances have led to that in countries such as Japan and United States, who are suffering a continuous decline in production since 1997, the respective Governments are studying measures to support the sector.

Participants were of the view that in many cases the origin of the tensions in the market is result of transfers of business clients to countries with lower labour costs, which means a decrease in the demand for moulds and dies in the countries of origin and an increase in the new countries of destination and its neighbors.

It was also felt that Governments can contribute both to improve the environmental conditions such as those relating to the abusive conditions of payment applied by certain customers and to the intellectual property of the mold, and to encourage the investments required to maintain a good level of technology through tax incentives.

As final conclusions it coincided in that technology, innovation and organization, together with appropriate size and a degree of specialization are key factors to offer customers an ever more rapid and complete service that ranges from the design of the product to the testing of mouldspreserial and dimensional monitoring them, counting for it with increased collaboration and strategic alliances between companies of the sector and greater use of the services of specialized technical centres. All this without renouncing the own know-how which is the main added value and differentiating element that can offer the moldistas and millwrights to customers at any time.

Related Companies or Entities

EOS GmbH - Electro Optical Systems

Hexagon Manufacturing Intelligence