Improvements in the turning and milling of medical implants

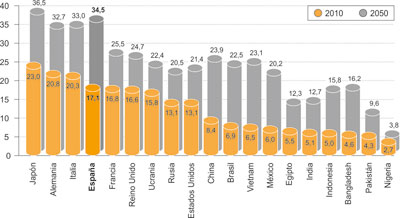

La industria médica continúa su crecimiento dinámico y sigue siendo un importante reto en el diseño de herramientas adecuadas para el sector. Este continuo crecimiento es el resultado de una exhaustiva labor de investigación y desarrollo de productos que mejoran la calidad y el incremento de la esperanza de vida en las regiones occidentales y asiáticas. Esta circunstancia contribuye en gran medida al crecimiento del mercado de implantes ortopédicos. Es por ello que los fabricantes buscan constantemente nuevos y mejores herramientas y centros de torneado para garantizar la competitividad.

El material más utilizado para fabricar implantes está compuesto por el 6% de aluminio, el 4% de vanadio y el 90% de titanio, comúnmente se le denomina Ti6Al4V. El 10% restante del mercado es para el acero inoxidable 316L, utilizado principalmente para alérgicos al titanio. La mayor parte de cirujanos prefieren el Ti6Al4V porque el tejido humano se adhiere a él mucho mejor que al acero. Las personas dedicadas a la búsqueda de materiales trabajan actualmente para conseguir una aleación de titanio de mayor pureza para acortar el tiempo de recuperación de los pacientes.

Por otra parte, la industria médica utiliza diferentes máquinas para aplicaciones de fresado y torneado. Para aplicaciones de fresado se suelen utilizar equipos con husillos de gran velocidad y avanzadas tecnologías, que permiten un cambio rápido de herramientas. El equipo habitual de torneado se compone de pequeños tornos CNC equipados con la última tecnología (software, husillos, portaherramientas, etc.) para una rápida y precisa producción de grandes series.

The world-wide demand of pieces for the medical industry torneadas of precision is definitively increasing, especially regarding implants ortopédicos and dental. This is had to, partly, to the aging of the population: those that more years live, more implants need. Changing to the plaquitas Pentacut with coating PVD of

By this is not surprising the high existent competition in this sector. The business will carry it to him the provider that no only offer an extremada precision and efficiency in materials of scarce maquinabilidad, but also a capacity to develop prototypes, to give a fast answer and that was had to supply small quantities. The work with some so difficult materials to mechanise and costly and with batches of manufacture so small, leaves very little margin for the error. To be competitive and profitable in this speciality, is necessary to hit to the first.

The good news is the current availability of advanced tools specifically designed so that the production of pieces for the medical industry was better and faster. The correct selection of the tool, and of his spare parts, can with frequency duplicate them parameters of cutting or the length of the edge, improve the control of shaving and delete the deformations of pieces of thin or difficult walls to tie up.

For example: When a manufacturer of dental implants produces a piece in an automatic lathe (see fig. 1), the plaquitas fall premature and impredeciblemente, often owing to an astillamiento or break of the edge. The half length of the edge is 90 pieces, but the range is so wide and miscellaneous, that the half ‘term' lose his sense. Therefore, the operation needs the constant attention of the operario.

Por ejemplo: Cuando un fabricante de implantes dentales produce una pieza en un torno automático (ver fig. 1), las plaquitas se caen prematura e impredeciblemente, a menudo a causa de un astillamiento o rotura del filo. La duración media del filo es 90 piezas, pero la gama es tan amplia y variada, que el término ‘media’ pierde su sentido. Por tanto, la operación necesita la atención constante del operario.

Changing to the plaquitas Pentacut with coating PVD of Iscar in a tool holders with fixation by screw very rigid, achieved a length of the edge of cut of until 250 pieces by edge and an excellent superficial finishing. The failure was gradual and the wear of the edge of predictable cutting according to the deterioration of the superficial finishing. The operation could carry out without need of a tención continuous. The key factor for this improvement is the fixation, extremely rigid, that keeps the plaquitas in his place.

Three common denominators

In this case, extracted more than the half of the original weight of metal, an appearance of the turning of medical components that is used to to overlook. Although it treats of small pieces, the volume of metal to extract is relatively big. Already it was in small automatic lathes or lathing centres, in the mechanised of pieces for the medical industry usually splits of a bar maciza and tornean diameters very staggered. The final piece weighs much less that before the mechanised.

Another common denominator in the turning of pieces for the medical industry is that the material is used to to have little maquinabilidad. The main materials that use are elastic stainless steels and other alloys with basic nickel, titanium and alloys to high temperatures. In the selection of the materials, the biocompatibilidad, the resistance to the corrosion and an extremada resistance prevail on the maquinabilidad.

The geometry of the piece can join to these factors. The tubes of thin walls, especially of aluminium, have tendency to deform , unless the edges of cut are very alive. A lot of pieces can be asymmetric, with complex curves that can interfere with the fixations and supports. This does that it was fundamental to minimise the strengths of cut, so that the piece mechanise without deforming . Especially, the RPM have to adjust to keep the suitable speed while the diameter reduces in these difficult materials.

Advances tested, sizes smaller

Fortunately, at present exist important advances in the tools for materials of difficult mechanisation, for the small dimensions required for medical implants. The new coatings reduce the friction, the heat generated and the causes of the microscopic tensions that produce the break of the edge. The advanced qualities of hard metal give excellent results, even with cut interrupted. The rompevirutas more aggressive and the refrigeration through the tool improve the evacuation and control of the shaving, and reduce the possibility to go back to cut the shavings until in the deepest holes. The systems of fixation safer keep the plaquita in position and delete the microvibraciones associated with the movement of the plaquita in the seat.

The coatings of last technology improve the performance 35%

Does some three years, Iscar launched the treatment postrecubrimiento GREAT-TEC, designed to do the coating of the plaquita softer and uniform, by what cushions the three main enemies of the length of the plaquita: friction, heat and agents that generate tensions. In that moment, this technology only was available for a limited selection of plaquitas of milling and turning. The experience has showed that the GREAT treatment-TEC improves the efficiency an average of 35%, taking into account the performance and the length of the edge of cutting. Since, Iscar has expanded regularly the capacity of the treatment and has extended it to a wider range of plaquitas, included the ones of lower size, necessary for implants and prosthesis. Nowadays more than 40% of the plaquitas Iscarde hard metal are available with GREAT coating-TEC like standard.

Relation between qualities and applications

To continuation will analyse in detail the qualities of hard metal that are improving the turning of components used in the medical industry to world-wide level.

Quality IC 807, quality submicron with coating TiAN PVD and GREAT treatment TEC. It is adapted for mechanised to half speed in stainless steels austeníticos, resistant alloys to the heat and temperate steels. Thanks to the treatment postrecubrimiento GREAT TEC, offers an excellent resistance to the recrecimiento of the edge in steels.

Quality IC 808, sustrato hard with the same coating and treatment that the Quality IC807. It offers a high resistance to the wear and to the astillamiento in a wide range of materials, also in applications of cut interrupted.

Quality IC 328, extratenaz with coating TiCN, and the new quality IC830 with GREAT treatment TEC, are excellent in applications of milling, tronzado, ranurado and turning, in simple stainless steels and aleados.

Quality IC 928, adapted for applications of desbaste heavy and cut interrupted, in all the metals used in implants. Sustrato tenaz With coating PVD TiAlN.

Rompevirutas

The selection of the rompevirutas correct can mean a big difference in small pieces of difficult materials to mechanise. Iscar Has of the following rompevirutas:

- For general turning and good finishing superficial of all the metals, included the aluminium, the rompevirutas type ACE is the ideal by the edges of alive cut, detachment polishing very positive.

- For applications more difficult, like tronzado and ranurado, tubes of thin walls of soft and elastic materials, is necessary to use rompevirutas more aggressive, like the types J, JS and JT. His edges of cut are more alive and the detachment is very elevated for a better control of shaving

The threaded by eddy protects slim pieces

For the threaded of slim pieces can apply a process multiherramienta that no the shapeless, this process designates eddy. The multiple tools, separate simétricamente, balance the strengths of cut of a way that an alone tool could not.

Now Iscar offers plaquitas specific for this process (see fig. 2). They use with big success in the threaded by eddy of screws of titanium for bones.

Evacuation of shavings in small spaces

In the inner turning, the evacuation and the control of shaving always have been a problem, especially in elastic materials that form long shavings. The complete line of tools Mincut of Iscar for ranurado solve these problems, thanks to his internal refrigeration. The tool holders have of a system of fixation very rigid that prolongs the length of the edge of cutting and improves the process.

Are available for diameters of until 8 mm, are very safe for applications of ranurado, reliefs and mechanised of channels in holes very deep. The tools MIincut also can realizar operations of ranurado frontal with depths of until 5.5 mm.

Iscar Offers better solutions more quickly

Have developed similar improvements in the field of milling of implants. Recently it mechanised a prosthesis of knee of chromium cobalt with a special strawberry of Iscar of 8 lips, giving as resulted a reduction of the cycle of mechanised of more than 40%.

Is clear that the mechanised of destined components to the medical industry is a sector in growth with a big future. As it occurs with other productive sectors, the demand will keep growing, the same that the competitiveness. The optimum selection of some tools advanced, now widely available in the small sizes required, can suppose a big difference in efficiency and profitability.

The solutions of last technology of mechanised and innovative products that offers Iscar will increase his productivity and profitability, guaranteeing him a highly competitive position in the mechanised of pieces for the medical industry.