New solutions of repair in the aeronautical sector component manufacturing sector component manufacturing industry

Researchers of the

In the actuality the aeronautical sector component manufacturing sector component manufacturing industry poses the need to improve the technicians of repair of the metallic components inside the structure of the aeroplanes, so much in the parts of the engine as in some structural elements. In this context, researchers of the University Rey Juan Carlos (URJC) look for solutions and new technicians through his participation in the European project Cold Spray Radical Solutions for Aeronautic Improved Repairs (Corsari). The aim is to surpass the current technological limitations and achieve systems more effective of maintenance and repair of aeronautical sector component manufacturing sector component manufacturing components to extend the life of the aeroplanes.

For the moment, the team has developed new alloys of trióxido of aluminium with niquel (Neither-To the2Or3), in this case more focused to the industry of generation of power. The details have published in the Journal of thermal sensors sensors Spray Technology.

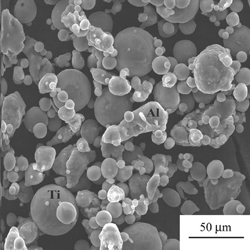

This study and the own consortium Corsari base in the processes of cold spray or cold projection, a relatively new technician –the first patent dates of the years 90– that presents advantages to deposit alloys ligereas, fundamentally with base of titanium, aluminium and magnesium. According to his promoters, his development is the sufficiently mature to explore his industrial utilisation.

The Department of Mechanical Technology of the University Rey Juan Carlos forms part of this European consortium of multidisciplinary character composed by different groups of investigation of European universities (Polytechnical gave Milano and the National Aerospace University Kharkiv) and distinct technology centres (Veneto Nanotech and TWI). The application in the aeronautical sector component manufacturing sector component manufacturing industry has contributed to that companies of the sector also are involved, as they are the Spaniards Iberia Maintenance and Airbus Military and other Europeans (General Electric Avio, EADS Deutschland GMBH, MetaLogic, Impact Innovations, LPW Technology and EASN-TIS).

The main contribution of the group of investigation of the URJC, led by Pedro Alberto Poza, chair of university and director of the Department of Mechanical Technology, consists in the characterisation of the coatings processed by cold projection during the project.

The researchers treat to repair better the trains of landing and the gear boxes of the aeroplanes

“Carry time collaborating with Veneto Nanotech, those who have a big capacity of manufacture by means of the technician of cold spray and we are studying the materials that are manufacturing. In these moments, already have selected the aeronautical sector component manufacturing sector component manufacturing components that would interest to repair by means of this technician, as they can be the trains of landing or the gear boxes of the aeroplanes, and the materials that go to study, that are light alloys of aluminium, titanium and magnesium”, explains Pedro To. Poza.

Manufacture to low temperature

The main advantage of the processes cold spray, in front of the technicians of manufacture of coatings to high temperature –where the material that deposits is subjected to strong residual tensions and his stability is conditioned by these circumstances–, is that they realizar to relatively low temperature (between 200°C and 500°C) and allow to develop thicknesses sufficiently thick, whereas with the technical plasma or high speed is not possible.

On the other hand, the alloys that use during the process of manufacture are very sensitive to the high temperatures and, therefore, his properties can degrade significantly during exhibitions of these characteristics.

Besides, this project poses objective of commercial character, since the repair of a component in place of his replacement would suppose a cheapening of the costs to the not to need raw materials, and constitutes also an ecological challenge, in the sense that the materials reutilizarían. “Other conventional technicians use gases contaminantes in the processes of manufacture. However, cold spray only needs gas nitrogen”, signals Poza.

The project Corsair finds in a second phase and this week gather all the members of the consortium in the URJC to argue how begin to realizar the materials in probetas of laboratory and, on the other hand, in probetas that simulate aeronautical sector component manufacturing sector component manufacturing real defects. According to the researcher, “our following committed will be to realizar the characterisation of the behaviour of these coatings. The aim is to achieve that the material repaired have the same properties that the original”.

The mechanical properties of the coatings will be analysed using methods of nanoindentación. These technicians consist in applying loads very small on a volume of material no too big to obtain the new mechanical properties of the material repaired and compare them with which had the original material.

Another factor that will analyse the team will be the microstructure of these materials by means of microscopía electronic of transmission, with the end to find the optimum parameters of the process of manufacture that provide the most adapted microstructure to attain the properties wished.