Facilitating the mechanised of pieces of 5 axles

Aitor López, MTP Product Manager of

In addition to working with manufacturers Prevail and Tier 1 of the aerospace sector of all the world, the experience of MSP in processes of mechanised has allowed them extend quickly to other sectors, especially to the industry of the composites, where the systems of MSP are widely widespread, and to the manufacture to measure of pieces of Formula 1. Like this, the signature has worked with the manufacturer of systems of defence, BAE Systems, that has contributed him a saving of 21 million pounds (during the life of the piece) only in the manufacture of a piece of the most advanced military hunting that exists at present, the F35 II Lightening.

The team of project of BAE Systems percató that to solve the problems of manufacture of the Nozzle Bay Door needed skilled help for a so complex piece. MSP Was invited to review the project to look for a satisfactory exit. They identified three areas of improvement 1) tooling of tie up, 2) alignment of piece and 3) keep the quality of the geometry of the machine in a high level.

The team of production of BAE Systems designed a revolutionary tooling for the piece. By his part MSP implemented his system NC-PerfectPart for firstly chequear the capacity of the machine before verifying that the alignment of the piece was inside tolerance. Everything simply with a touch of button of the operario.

The speed and precision that comported this conjoint effort in the manufacture of the Nozzle Bay Door allowed to win to the equipment of project of BAE Systems and MSP the prize BAE Systems Chairman's GOLD Award of 2013, selected among others 1.000 projects and innovations.

Reduce the alignment of piece to 10% of the current time reports important savings of production

NC-Checker Is a simple system and automated that a mecanizador can use to create a ‘signature' of a machine/specific piece. This signature allows to monitor and check the state of his machines to level of operario with simple screens HAPPENS/DOES not HAPPEN. It allows to know if the machine is or is not able to produce the piece. Using NC-Checker can know , before beginning to mechanise the pieces, if the machine is able to manufacture it, identifying and deleting in advance errors of machine in the first step of the productive process. The operario simply follows the sequence of proofs and the system generates a simple report to read of state of machine.

This report indicates to the operario if the machine has happened the proofs and if it is apt to work. In contrary case will indicate the areas that are out of tolerance to inform to the department of maintenance and correct the errors detected that they allow can give back the machine inside tolerances before initiating the production.

The proofs of state of machine can execute along the time to detect tendencies and if some parameter of error goes growing will be easily identifiable so that the manufacturer can resolve proactivamente this focus of error of preventive form, before it suppose a grave and costly failure.

By his part, NC-PerfectPart, of the that forms part the module NC-Checker, is an advanced system of alignment that improves the capacity of his machine of 5 axles and is based in a simple interface of operario. Using initially NC-Checker can know if the geometry of the machine is able to manufacture the piece wished and the report of becnhmark (described before) will show it.

Once checked that his machine is geometrically able to produce the piece inside tolerances, can proceed to use NC-Partlocator to range a complex piece. The alignment allows an easy mechanised of avellanados conical, cylindrical and check the distortion of the material. Again, this operation executes by part of an operario of the machine, providing simple and direct messages.

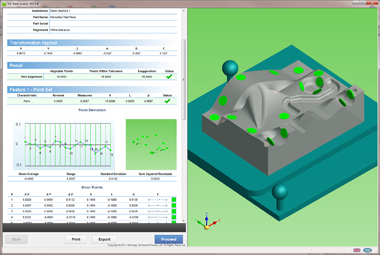

Once that they have executed the routines of inspection, a screen will inform to the operario of the alignment of the pieces. If the piece is properly ranged the screen will show green colour and the piece will be had for the mechanised.

Screen in colour green, informs that the piece is properly ranged for his mechanised.

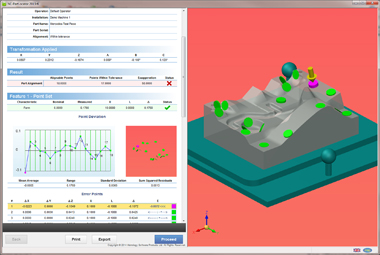

However, if the screen shows red colour, exists an error of alignment, that would have to be solved before the mechanised.

Screen in colour red, that informs of an error of alignment that has to solve before the mechanised.

This misalignment can be compensated using our macros of CNC relative to the file CAD of the piece that automatically will do the necessary corrections without any type of manual intervention or of the operario. In this way it avoids the creation of additional errors by part of the operario when taking part manually in the process.

Once calculated the automatic compensations, the operario will be able to see another screen indicating adjust them of alignment that have realizar and trust fully in that the piece will realizar of satisfactory form.

In this process, MSP works together with Renishaw to give support to his customers from the first steps of definition of the project.