Aimplas Develops a new method of manufacture of profiles for the construction and the electrical car

27 January 2014

The Technological Institute of the plastic,

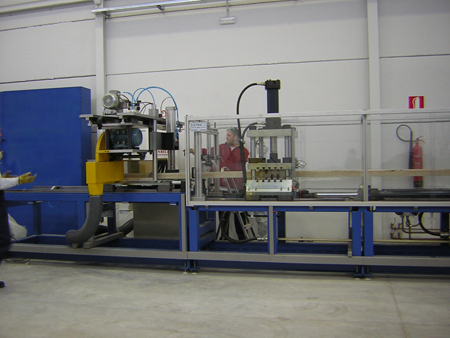

Specifically, the advantages of the new process of manufacture allow no only reduce the hand of necessary work for the production, but it also avoids steps in the process like the lijado and the back painted or application of first. Thus, it results faster and economic and besides more sustainable medioambientalmente, since it avoids the broadcast to the environingingment of solid particles during the lijado and of volatile compounds during the painted.

As it explains Nora Lardiés, main researcher of the project in Aimplas: “The process of manufacture of profiles by means of pultrusión is a process in continuous in which it enters a reinforcement of fibres of glass impregnated with resin by an extreme of an enclosed mould and calefactado. The resin cures in the interior of the mould by what by the another extreme of the same goes out the practically cured profile”. In Coaline what pretends do is recubrir the profile inside the mould, “that is to say, apply the painting or, in his case the first, inside the mould, with what will achieve save time and will not issue to the acclimatise pertinent solid particles of the lijado neither neither COV (compound organic volatile) of the painting or of the first. It will be a much more effective process, economic and clean”, ensures Lardiés.

The industrial application of the project Coaline will come of the hand of the two partners of the consortium that will act like final users: Acciona and Alkè. The first will use the profiles obtained by the new method of production like beams of reinforcement in the sector of the construction, whereas by his activity, Alkè will apply them in the structure of electrical trucks.