A review of the milling

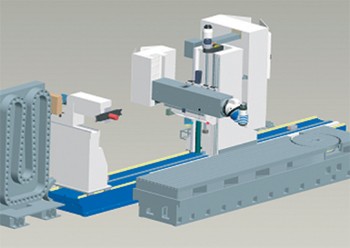

Centre of milling

The centres of milling of the FL Center-6000 series can be equipped of electrohusillos of high speed, from 18,000 to 30,000 rpm for finishing operations and high speed work. In addition, they can be equipped with system of integral fairing and dust and smoke extraction systems.

It has a surface of 6000 x 1,100 mm table and an integrated turntable with a diameter of 1,000 mm. Rapid advances in the X, Y, Z axes are 25,000 mm/min and the progress of work are 5 to 10,000 mm/min. It includes alamcén for 80 tools and numerical control Heidenhain iTNC-530.

Milling machine table fixed

As a main technical characteristics, the model Diana dispjnme of a longitudinal distance of 2,000-2,500 mm, a journey of 1,000 mm and a vertical distance of 1000 mm. Advances are 20 m/min and includes manual and automatic headers and fairing integral semi.

CNC milling machine

As CNC controllers incorporated the Mitsubishi series 64/45, Fanuc 18 M/Oi-Mate B, fagor 8055MA/8055MB or Siemens 802D/810D. The system of inspection is done by circle of bar of balls with identification of high-accuracy, errors of servo and geometry, statistics and dynamically.

Geometric errors of the axial movement of the machine include: precision of positioning error of step and slack and they may be submitted precisely by inspection by laser.

As technical characteristics, model NC-454LA has a 10.000/24.000 rpm spindle speed, the drive of spindle is via strap H.T.D and the cone of spindle is 40.

It has a warehouse with a capacity for 10 tools, the handle of the tools is type BT40. It accepts a maximum diameter of tools of 75 mm and a maximum length of 125 mm with a maximum weight of 6 kg.

The spindle motor is 5.5/7.5 kW of power and integrates a coolant pump for 1/4 HP of power. Lubrication pump is of 120W and motors of the axes X, Y, Z are 5.1 nm.

Center of turning and machining

This pick-up machining centre allows operations in position horizontally, vertically or in any intermediate position.

It is designed to meet the requirements of machining of complex parts. Allows more operations of turning, drilling, threading, slotted notches and machining of straight or sloping faces in a single subject. It is possible to perform on the same machine so delicate as eccentric drilling operations either inclined, helical grooves, milling of cages, as well as taladrados of deep holes and also many more operations.

Equipped with a storage of tools, this machining centre is adapted for production in small, medium or large series.

CNC milling machine

It has a surface of table of 1,800 x 450 mm with five slots 16 mm in width. The distance between the grooves is 60 mm and the maximum permissible load of the Bureau is 1,300 mm.

The longitudinal course (X axis) is 1500 mm, the transverse course (axis and) is 650 mm and vertical course (Z axis) is 620 mm. The distance from the nose of the main shaft to the table is at least 100 mm and 720 mm as maximum. For its part, the distance from the Centre of the main shaft protection is 585 mm.

Rapid advances in the x/Y axis are 18,000 mm/min and advances of the Z axis are 12,000 mm/min. Includes a shaft Chuck cone type Mas 403 BT 40 with pneumatic locking system of the cone. The range of speeds is 100 to 6,000 rpm, although it can optionally be 100 to 8,000 rpm.

CNC milling machine

It's a versatile machine designed to offer machining at high speed.

As a main technical data, the 5000 series has 5.5 to 16 HP and table size since 1.270 x 1,270 mm 3.050 mm x 9,100. It accepts a maximum weight with a maximum of 1.580 kg up to 9,000 kg.

Milling machines for crankshafts

In this way, "gemini" is suitable for horizontal fixing of these milling machines and for the measurement of the cutting edges in the perimeter by transmitted light. The treatment is optimized and the special procedures of software developed in Zoller also allow the measurement of cutting edges very contiguous, automatically removing the little sharp positions in the area of the plane.

To measure automatically crankshafts with internal cutting edges milling machines Zoller has also developed the apparatus measuring "aralon", four-axis CNC control and automatic measurement contact head. After the fixing of the milling of crankshafts with internal cutting edges in the portaadaptadores special, equipped with underpinning of the loading and Automatic centering, fully automatic measuring process begins. This system provides options to determine the flatness and the concentricidad and issue stepped distances. It also includes system of automatic compensation of the concentricidad, query by using push button and two positions of security used automatically by the system.

Vertical milling machines

In particular, the FV 251 M model has a size of 250 x 1,120 mm table with displacement in X/Y/Z of 820/280/410 mm and a speed of 40 to 2,000 rpm spindle. The progress of table X, Y/Z is 12.5 to 630 and 5 to 262 mm/min. The rapid progress of the table is 2.500/1.040 mm/min. Integrates a single spindle cone type ISO 40 and an engine with a power of 4 kW.

The FV 281 model for its part has a size of 280 x 1,200 mm table and a few X/Y/Z of 900/280/410 mm displacement The revolutions of the spindle are 45 to 2,000 rpm and the advance of table X, Y/Z is 2.500/1.040 mm/min. Integrates a single spindle cone type ISO 40 and a power of 4 kW engine.

The FV 301 model offers similar benefits to the FV 281 model but with different size of table, 300 x 1,250 mm and with a few X/Y/Z displacement of 950/320/410 mm. Equal to the previous model integrates a single spindle cone type ISO 40 and a power of 4 kW engine.

FV 321 M, 361 FV and PV 401 models make up a single spindle cone type ISO 50 and a 5.5 kW engine power. The rapid macha of the table X, and / Z is 2.500/1.040 mm/min with an advance of 12.5 X, Y/Z table to 630 mm/min/from 5 to 262 mm/min. The revolutions of the spindle are 45 to 2,000 rpm. Displacement in X/Y/Z in the FV 321 M model are 1.000/360/460 mm; the FV 361 model are 1.150/360/460 mm while that model PV 401 is 1.250/360/460 mm. The table size is 320 x 1,350 mm; FV 361 is 360 x 1,500 mm in the model and model 401 FV is 400 x 1600 mm

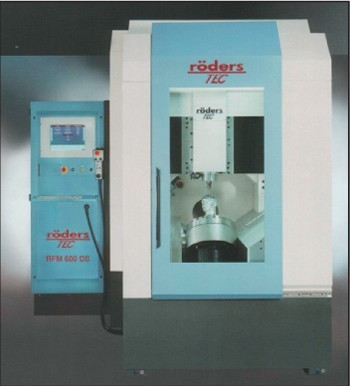

High speed milling

It has good visibility and accessibility to the work area, allowing the loading by crane or robot. It incorporates a changer auto tools to store of 26 stations, including laser to measure tool. Pressurization is with air system to stabilize the temperature of the machine. The maximum advance system is 30 m/min with a maximum speed of the spindle of 42,000 rpm.

In addition, the RFM600DPS model incorporates Automatic palletizing both pieces of work and a long range of machining tools.

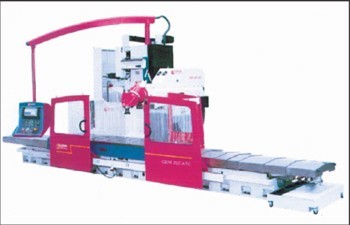

Milling machine table fixed

Available different CNC, Heidenheim iTNC530, Fagor 8055 MC/C, Selca S4040D/S4045D, Fanuc 18i, Siemens 840 d. Includes linear rules of uptake of the three axes (X, Y, Z) and direction of the main shaft (threaded rigid) and portable electronic steering wheel.

The engines are digital, to head and axes and integrated hydraulic counterweight to compensation of vertical carriage, carnero and head. It has complete installation of refrigeration, with tank and motor pump. The heat exchanger is in the Cabinet and is pedal for mooring and untying of tools.

There is a wide range of options to incorporate: telediagnosis, automatic head (2.5 ° x 2.5 °) and semi-automatic, head of 4,000 rpm, speed multipliers, portable and fixed spindle of high speed electrical splitter plates for the fourth and the fifth axis, high pressure through the tool taladrina, stores of tools, thermal compensation in all three axes, different electronic probes to measure tools or measure pieces and integral fairing.

Milling boring

The vertical axis of the transom is 2,000 mm to 3,000 or 4,000 mm option, and is indexed every 500 mm.

Incorporates a CNC Siemens 840 d and the turntable has 360 positions. It has a maximum of 80 kW power. The advance is 20 m/min, and the storage of tools includes 30 positions with option of 30 + 30. The cone of the tool is interaction.

Its dimensions are 3,000 mm in width and 3,000 mm in height, or 4,000 mm of width 4,000 mm in height.

The carrying capacity of the bench is from 8,000 to 15,000 kg/m2. Turning maximum speed is 70 rpm and plate turning diameter is 4 metres.

Milling machines with greater speed, repeatability and accuracy

They have linear guides in all three axes that guarantee a higher speed without losing the optimal level of stiffness due to the perfect sizing of rolling skates roller. (G) Cosmos, Master G and G Galaxy models are a solution of first level for all types of applications, from the preparation to the finish in light and resistant materials; from the manufacturing of moulds and dies to general purpose machining.

Applied to the technological line of machine, precision, speed, power, service and universality are the five necessary elements that characterize these milling machines.

Fresadora-copiadora

The head has device of unemployment to the height desired for milling.

The fresadora-copiadora incorporates a table with 500 x 280 mm measures It has a longitudinal distance of 260 mm, a transverse distance of 140 mm and a vertical displacement of 100 mm.

Lamáquina incorporates a motor 220V single-phase or three-phase 220/380 V 3. 000rpm and 1 HP of power and with a speed of 10,000 rpm work.

Accessories include: blowing gun cleaning, clip, fresolín, keys, template slotted and caps.