Biomecanizado: An approach to the remoción of metal in special applications

And. Díaz-Tena, To. Rodríguez-Ezquerro and L.N. López of Lacalle Marcaide of the Department of Mechanical Engineering, Upper Technical School of Engineering of Bilbao, UPV/EHU

L. Gurtubay Bustinduy And To. Elías Sáenz of the Department of Chemical Engineering and of the Environingingment, Upper Technical School of Engineering of Bilbao, UPV/EHU.

27/11/2013With this study looks for analyse the process of the 'mechanised biological' for the case of materials of high purity, specifically free copper of oxygen, being a first original approach to the possible utilisation of bacteria extremófilas for the elimination controlled of material in several fields. It does not treat to substitute to the mechanical processes, but to have a new process that allow to resolve cases of manufacture of forms or complex details.

First will realizar essays of chemical type, for later enter the bacteria of the family ferrooxidans in the process. In both cases, will be object of analysis so much the tax of start like the evolution of the superficial quality of the piece. Of this form explore technologies that although they do not have mechanical nature himself can coexistir in companies that do production of high value added.

1. Introduction

The copper participates direct and indirectly in applications so much traditional like emergent. His high level of industrialisation (of 10 to 15 kg/Cu/year/person) and his high world-wide production, surpassing the 18 million tonnes [1], do that no only the demand of the copper grow with the progress, but at the same time it make possible that such progress take place. In the last years the demand of the copper for employment of equipments in subjects of R&D, in electronics equipment dealers equipment dealers and in medical equipment has seen increased and according to the Figure 1, foresees an exponential growth in the near future.

One of the coppers with greater peak in the actuality is the free copper of oxygen (OFC), characterised by his high level of purity (mín. 99.999 %Cu) and his high electrical conductivity. One of his applications of greater importance in our industrial surroundings is his use in particle accelerators and other big scientific instruments. In this type of installations require pieces with finishings of polishing to mirror (rugosidad inferior to 0.1 m) and with precisions in the order of 5 m in 10 m. Another field is the microelectrónica and microactuadores, where in addition to processes of classical cut have to explore other even founded possibilities in other fields of the technician of different cultural order. This is the case of the biomecanizado, whose first results analyse in this work.

2. The process of biomecanizado

The most common processes in the field of the mechanised, like spark-erosion, milling or mechanised chemist among others, present the disadvantage to be able to affect so much thermal sensors like mecánicamente to the material owing to the temperatures reached during the process, the lubrication and the physical contact between tool and piece. When pursuing the idea to achieve high requests of quality and low superficial affectation, arises the need to open new lines of investigation, improving technical existent or even betting by new methods of manufacture.

Example of this is the mechanised by means of bacteria (also known like biomecanizado) process in which by means of chemical reactions chained achieves the remoción of material. Unlike other processes, here do not employ tools of cut, neither toxic compounds (as it is it the FeCl3 of the mechanised chemist), by what does not exert any mechanical damage neither thermal sensors on the surface mechanised. The process of the biomecanizado has been object of few studies [2-5], tried do a gap in the industrial field substituting/complementing to processes like microfresado, micro/EDM or mechanised chemist.

The cation Faith3+ is the fundamental chemical species in the process of remoción of metallic copper in dissolution of sulphurous acid by means of the utilisation of the bacterium Acidithiobacillus Ferrooxidans (To.F.) (Figure 2). In the ready dissolution between other chemical species finds the cation Faith2+ in addition to the bacteria To.F.. These, in his metabolic process oxidan the Faith2+ to Faith3+. When entering the probeta of copper in the dissolution, the Faith3+ generated oxida to the metallic copper, that dissolves like cation Cu2+ and simultaneously reduces to Faith2+. The Faith2+ will be oxidado again to Faith3+ by the bacteria, continuing like this the process of biomecanizado. This process, therefore it is enclosed, autonomous and if it stabilises is susceptible to be used industrialmente. Even it can open other lines, since there are references to possible applications on other metals and alloys.

3. Experimental development

The main aim of this study was to expand the knowledges on the mechanised of copper by means of bacteria To.F. (Figure 2), analysing the effect of said process on the metallic surface, so much in superficial quality as in tax of remoción. Likewise, it pretended analyse the different factors that could arrive to have influence in the results of the process: physical parameters and chemists and conditions of treatment among others.

The crop of bacteria To.F. Employee in this study, was supplied by researchers of the University of Cádiz, expert group in working with this type of bacteria. The concentration bacteriana was unknown.

3.1. Design of the probetas

Prepared probetas of useful surface of 10x10 mm2. These dimensions asemejaban to the used in the essays of the articles related with the subject of the biomecanizado [2-4], being in his majority probetas square and of small thickness. The thickness fixed in this case went of 2 mm.

3.2 Phase of feasibility of the technology

3.2.1 initial Proofs of probetas entered in the River Tinto, Huelva

Like first approach to the study, decided enter several probetas in a half bacteriano natural active, as it is it River Tinto (situated in the province of Huelva). His high biological diversity and his half pH of 2.3 make possible that bacteria oxidants of the ironinging convivan in this unusual ecosystem. This example served of initial inspiration to the project, as the reply of a half natural stable like the Rio Tinto could illustrate on the basic of the problem and identify strains of bacteria among others.

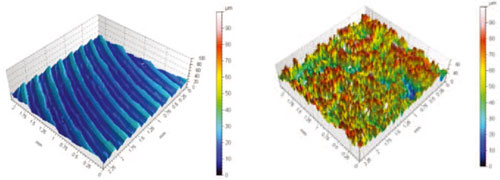

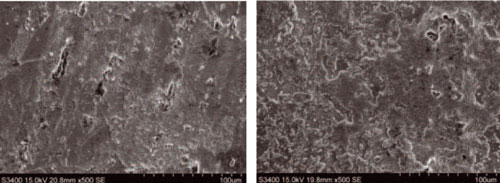

The probetas extracted each 15 days, analysed road SEM and observed microscópicamente, repeating the process along 2 months. Although it did not have complete knowledge of the process that was occurring, could observe a decrease in the mass of the probetas, as well as an impairment of the superficial quality (Figure 3), concluding that the time of exhibition had been elevated. Obviously the attack combined bacteriological/chemist was in all the surface, so much in valleys as in crests.

3.2.2. Initial proofs in laboratory (mechanised chemist)

With the end to purchase previous experience to the introduction of the bacteria, realizar a series of essays with two dissolutions of Faith3+ prepared from ferric salts in half sulphurous (pH=2), of concentrations of cation of 1 and 5 g/L. They entered the probetas of copper, previously heavy, suspended in the breast of the dissolutions (see Figure 4) and processed with orbital agitation (90 rpm) to two temperatures (26 and 56 °C). At intervals of time of 15-30-45-60-75 and 90 minutes, the probetas washed , dried and weighed to determine the loss of mass of copper of the same. Likewise, it determined the concentration of Faith3+, in addition to other parameters.

After the ending of the essays, the surface of each probeta analysed by SEM and by means of an optical microscope confocal. The results show in the Section 4.

3.3. Phase with bacteria (biomecanizado)

For the realisation of this phase was necessary to prepare firstly the half of crop bacteriano 9K, used usually with the bacteria To.F., with a concentration of 6 gFe2+/L and pH=2 [4,5].

Prepared the half, the following step was to give beginning to the growth of the bacteria. For this, to 150 mL of Half 9K added 2 mL of the inoculum of To.F. Supplied. The dissolution kept incubando during 48 hours with agitation of 150 rpm and to a temperature of some 30 oC. It knew that the growth of the bacteria had been satisfactory when having oxidado the greater part of Faith2+ to Faith3+ because of the metabolic process of the bacteria, as it has quoted in the Section 2.

To continuation gave step the first essay of biomecanizado. In jars of polyethylene entered dissolution 9K, inoculum bacteriano (To.F.) Grown and the probetas to test previously heavy. The jars treated with orbital agitation (150 rpm) to some 35 °C of temperature. At intervals of time of 1-2-3 and 4.5 hours, the probetas extracted of the dissolutions and after his wash and dried weighed . In the dissolutions measured the quoted parameters in the previous phase. Finally, the probetas analysed superficialmente, by microscopía optical confocal and by road SEM.

With the end to analyse the influence of the concentration bacteriana in the loss of copper, realizar simultaneously three analogous essays to the previous, in which three probetas were submerged in three means: And-100, with 100% of inoculum To.F., And-50, with 50% of inoculum To.F. And 50% of Half 9K and And-10, with 10% of inoculum To.F. And 90% Half 9K. Although it did not have knowledge of the initial concentrations of the bacteria To.F. In the inoculum supplied, of this way, knew that relatively the samples And-50 and And-10 had respectively 50% and 10% of the concentration bacteriana of the sample And-100. The results obtained of this phase with bacteria show in the Section 4.

4. Results

Mention, that the tax of remoción diminished systematically together with the decreasing of the concentration of the Faith3+ during the time of essay. Regarding the superficial quality, observed that to greater concentration of the cation Faith3+ this worsened, as it can appreciate in the Figure 6.

Regarding the effect of the concentration bacteriana, considering the losses of weight of copper to the of 1 hour and to the of 3 hours of the samples And-100 and And-50, could observe that the results of the And-50 were 50% of the found in And-100 in both cases. Of the same way, the values of the loss of mass accumulated of copper of the And-10 were of 12% and 13%, to the of 1 hour and to the of 3 hours respectively, of the corresponding to the And-100, very next to the relation of initial concentration between both samples (10%). These results summary in the chart of the Figure 8.

5. Conclusions and future works

In the essays of mechanised chemist, so much the concentration of Faith3+ like the temperature influenced notoriously in the taxles of remoción reached during the process. To greater concentration and greater temperature the tax increased. The superficial quality of the probetas tested worsened with the increase of the concentration of the cation Faith3+.

In comparison with the essays of mechanised without bacteria (mechanised chemist), by means of the biomecanizado reached taxles of remoción of similar copper to the first after the first hour of essay. Of similar way, in both cases the tax of remoción diminished over time of exhibition, being a no linear relation. In the essays with bacteria To.F., in theory, the tax of remoción of the copper would have to keep roughly constant. But it did not occur like this, although during the essay the concentration of Faith3+ remained more or less constant after each interval of time. This fact seems evidenciar the greater complexity of the biomecanizado in front of the mechanised chemist.

Of the results of the values of the taxles of remoción for different concentrations bacterianas, evidenció the existence of a direct relation between the concentration of To.F. And the tax of remoción of copper.

Thanks to this study, open new roads of investigation on the biomecanizado, like analysing in detail the evolution of the rugosidad superficial, guiding the process to the ‘control' of the same. It will work for achieving a continuous process with regard to his possible industrial application, incidiendo in the study of the potentially influential factors in the process, like agitation, temperature, pH and concentration bacteriana, among others.

At present, in the ETSI of Bilbao is working in a line of investigation focused to the development of an effective process of biomecanizado, through the study of the influence of the quoted factors in the same.

6. Gratitudes

The authors appreciate to SGIker the technical support supplied in the realisation of SEM and also the collaboration of the Centre of Astrobiology INTA-CSIC and to the University of Cádiz. This work has been possible thank you the financials received by the Basque Government and the UPV/EHU, this last under the program UFI 11/29.

References

[1] International Copper Study Group, http://www.icsg.org (Last access December 2012).

[2] J.Istiyanto, T. Jo Ko, II-C. Yoon. To Study on Copper Micromachining Using Microorganisms. International Journal of Precision Engineering and Manufacturing, 11 (2010), pp. 659-664.

[3] J.H. Chang, H. Hocheng, H.And. Chang, To. Shih. Metal Removal rate of Thiobacillus thiooxidans without pre-secreted metabolite. Journal of Materials Processing Technology, 201 (2008), pp. 560-564.

[4] D. Johnson, R. Warner, To. J. Shih. Surface Roughness and Material Removal Rate in Machining Using Microorganisms. Journal of Manufacturing Science and Engineering, 129 (2007), pp. 223-227.

[5] D. Zhang, And. Li, Possibility of biological micromachining used for metal removal. Science in China, Serices C Life Sciences 42 (1998), pp. 151-156.