Improvement of the productivity in pieces of the aeronautical sector component manufacturing sector component manufacturing sector by means of unions cushioned

Alex Churches and Julen Landa. IK4-Ideko

07/10/2013This work studies the capacity of sintonización and the increase of the stability of cut of slim pieces and of thin walls entering material viscoelástico (VEM) in the nearest unions to the point of cutting. The present investigation, funded by the project PoPJIM (260048) of the 7º Program Mark European, has showed the effectiveness of the union cushioned, that offers improvements of the capacity of cutting around 100% for any speed.

The aeronautical sector component manufacturing sector component manufacturing sector is a strategic bet of the Spanish industry, that has like aim strengthen the auxiliary industry and his customers, increase the weight of the exports in the production consolidated, increase the productivity and reinforce the existent technological capacities and of the future. These factors strengthen the position of this industry in the European market, allowing face up to the competitiveness of the emergent markets.

The aeronautical sector component manufacturing sector component manufacturing structures present complex forms and walls of low flexibility that, beside the drop maquinabilidad of some alloys like the titanium, hamper to a large extent the process of mechanised. This is a critical factor, because of the high value added that present usually this type of pieces. This work presents a new strategy to improve the manufacture and the productivity of pieces of thin walls and álabes by means of the modification of his modules of union.

Problematic and strategies of solution

In the processes of milling, the vibrations generated by the chatter pose a grave problem that hinders the process of cutting and puts in danger the quality of the surface of the piece, limiting the life so much of the tool as of the mechanical components of the machine. This effect car-aroused originates by the regeneration of the thickness of shaving that arises between two happened of consecutive edge of the tool.

With the end to obtain greater levels of productivity, have developed methods for the prediction of the stability and different strategies to solve the problems of chatter. An approach consists in modifying the conditions of cutting of the process: using the diagrams of stability like reference, can define the speed of optimum twist of the tool that allow to increase the capacity of cutting. Other technicians that act on the conditions of the process are the continuous variation of the speed of cut, the variation of the angle of the propeller of the tool or the no uniform step of the tool.

A different perspective to face up to the problems of stability bases in the increase of the dynamic rigidity of the structures to cut by means of the introduction of shock-absorbers passive and active. An amortiguador passive or absorber of dynamic vibration (DVA), is a device that enters a strength of inertia thanks to a mass sintonizada, increasing the amortiguamiento of the system. They have used successfully in toolings for machines of milling, reducing significantly the levels of vibration. By the contrary, the shock-absorbers active measure the speed of vibration and enter a strength controlled in phase and in the opposite steering, attaining a similar effect to the amortiguador passive.

Is very known that the amortiguación of systems of multiple components is practically defined by the structural unions. This characteristic offers the possibility to change the dynamic properties of the system varying only the rigidity and the amortiguamiento of his unions. Big part of the power of deformation of the way of critical vibration has to concentrate in the union with the end that this strategy was effective. Of this way, the characteristic dynamics of the system can be improved through his unions and his values can modify through a precarga controlled.

Numerical simulations

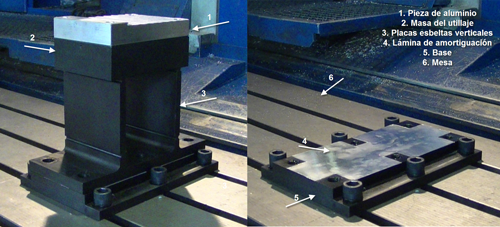

The flexible pieces of aeronautical sector component manufacturing sector component manufacturing use are used to to present values of amortiguamiento comprised between 0,3-0,8% to frequencies very diverse. With the end to imitate this type of structures and carry out analytical and experimental proofs, has used a flexible tooling with a dominant critical way (see Fig. 1). The tooling consists in an only piece, being a subject mass by two plates planted vertically that originate a way of main vibration. Thanks to the utilisation of a basic plate, has created a module of union atornillado that allows the introduction of the VEM between the base and the tooling. The device carries tieed up a piece of aluminium in his top to realizar mechanised and check the validity of the solutions posed.

The original system has been simulated by means of the method of finite elements (FEM) and have calculated different configurations of setting to cushion the system with the aim to identify the case that presents a greater dynamic rigidity and therefore a greater capacity of cutting.

The parameters studied have been the different types (112 of 3M and Sylomer SR-850), thicknesses and placings of the VEM. For this, have analysed different settings:

- Setting I: original system without plate of amortiguación

- Setting II: plate of amortiguación 112 of 3M of 1 mm of thickness in the base

- Setting III: plate of amortiguación 112 of 3M of 1 mm in the base and in the screws of union of tooling and basic

- Setting IV: plate of amortiguación 112 of 3M of 3 mm in the base

- Setting V: plate of amortiguación Sylomer SR-850 of 6 mm in the base

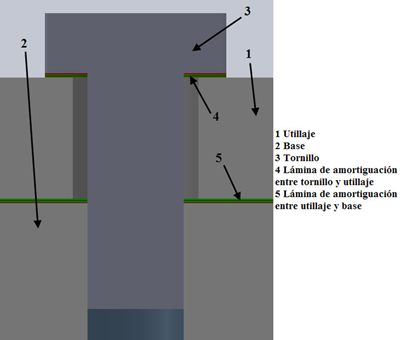

The plates of material viscoelástico entered in the base cover all the surface except the near zone that surrounds to the threaded holes. In the Setting III, also plants the plate of amortiguación between the screws and the flexible tooling (see Fig. 2).

In the simulations can observe that the Setting III presents the best dynamic answer of all, and the Settings II and IV also show a considerable improvement. By the contrary, the Setting V increases the amortiguamiento structural but has a big loss of rigidity, with what results similar to the no cushioned setting.

Experimental proofs

The numerical simulations of the different settings realizar have verified experimentally. For this, have compared the dynamic rigidity obtained experimentally with the calculated in the simulations. Finally they have carried out the proofs of cut to compare the limit of stability between the original tooling and the cushioned.

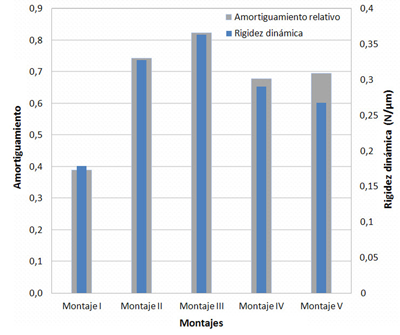

The experimental answer measure has been very similar to the obtained by means of the simulations except in the Setting III. The VEM placed under the screws does not work properly because of the excessive precarga that suffers the polymer in this point. The results of the dynamic rigidity and amortiguamiento experimental summary in the Fig. 3.

All the settings studied improve the dynamic rigidity of the tooling, being the Setting II the most suitable, where only enters a plate of amortiguación of 1 mm in the base. The increase of the thickness of the VEM entered diminishes the rigidity of the system.

To study the capacity of sintonización by means of the precarga entered in the screws, has measured the dynamic rigidity of the system with different pairs of tighten (270 Nm, 203 Nm and 135 Nm). For this has used the Setting II. The effect of the pair of tighten in the dynamic answer of the tooling is insignificant.

To study the effect in the capacity of cutting when entering the polymer in the union, have gone back to mount the Setting I and the Setting II. They have realizar planned in a piece of aluminium To the 7075 T6 with the tool HMKendu 902.60.020000.20 of 20 mm of diameter, 2 edges and 30º of angle of propeller. The proofs have realizar in concordance, with a radial immersion of 4 mm and an advance of 0,2 mm/tooth. The speeds studied have been 5.300, 5.500, 6.000, 7.000 and 8.000 rpm.

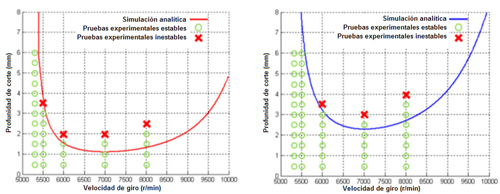

The stabilities of mock cutting with the dynamics of the two settings show a very important increase of the capacity of cut when it enters the material viscoelástico in the base of the tooling. The planned realizar in the tooling confirm this increase of stability. The correlation of the experimental proofs with the lobules of stability simulated is very precise (see Fig. 4).

Conclusions

The slim pieces of thin walls such like cashiers or álabes present a big limitation in the capacity of cut because of problems of vibrations, inherent to the low dynamic rigidity of the system. This limitation has seen improved by the introduction of material viscoelástico in the nearest unions to the point of cutting.

The simulations carried out show an improvement in the dynamic answer of the tooling when it enters material viscoelástico in his base, although this point was not the one who present the maximum power of deformation in the vibration of the critical way. The loss of static rigidity is not significant since the flexibility that present these pieces is of by himself very high.

The variation of the precarga of the screws or the increase of the thickness of the polymer entered in the base do not improve to a large extent the dynamics of the system. In structures where the union is not an important part of the global flexibility, the sintonización by means of the precarga of the union is not viable. The increase of the amortiguamiento is sufficient for the improvement of the capacity of cutting.

Has showed the effectiveness of the union cushioned, with experimental proofs that indicate that they can obtain improvements of the capacity of cutting around 100% for any speed.