Take out advantage by means of a mechanised heavy intelligent

Agustín Farré, general director of

Because of the strengths that appear during the mechanised, so much the machine like the tool see subjected to loads very high. Therefore, the aim of an improvement has to reside in increasing the volume of start of material, lengthening at the same time the times of useful life of the tool and reducing the solicitaciones on the machine.

Under the concept of ‘Dynamic Efficiency', Heidenhain resume a series of innovative functions of the TNC that help to the user to structure of a more efficient form the mechanised heavy and the desbaste. The functions of software support to the operario of the machine, doing besides to the own process of manufacture faster, stable and predictable, in summary, more efficient. For this combine effective functions of regulation with innovative strategies of mechanised, to end to increase the power of start of material and reduce the time of mechanised. ‘Dynamic Efficiency' Comprises three functions of software:

- Activate Chatter Control - The option ACC reduces the tendency to the vibration (chatter), allowing with this advances higher and depths of past greater.

- Adaptive Feed Control – The option AFC regulates the advance in function of the situation of the mechanised

- Milling trocoidal – Function for the acceleration of the desbaste of slots and cashiers with simultaneous protection of the tool

Each one of these solutions offers by himself same decisive improvements of the process of mechanised. But especially, the simultaneous combination of these three functions of the TNC takes advantage of all the potential of the machine and the tool, reducing at the same time the mechanical load. His employment is worthwhile. In the practice reach increases of the volume of start of shaving until a 20 or 25%.

During the desbaste, especially with hard materials to mechanise, appear strengths of cutting very high and can appear vibrations between the tool and the piece (chatter), producing unwanted marks on the surface of the piece.

ACC – Activate Chatter Control

During the desbaste, and especially with hard materials to mechanise, appear strengths of cutting very high. To the incidir of full the blades of the tool in the material can appear annoying vibrations between the tool and the piece (chatter) that produce unwanted marks on the surface of the piece. Besides, because of this vibration, the tool wears out more and of form less uniform. In cases desfavorables can give place even to the break of the tool. Also the machine tool is subjected to greater loads because of the chatter.

For the reduction of the tendency to the chatter Heidenhain offers, with the option ACC (Activate Chatter Control) of the TNC, an effective function of regulation. ACC Acts there where the vibration can be influenciada by means of the action on the bows of regulation. The algorithm of the function ACC increases the capacity of power of the machine, since they achieve greater depths of cutting and elevates the volume of start of material, arriving to be of more than 20% in determinate tasks of mechanised. Since the tool influences on the strengths of cut, which determines the characteristics of the eventual vibration by chatter that can appear, can assign to each individual tool a game of parameters ACC specific.

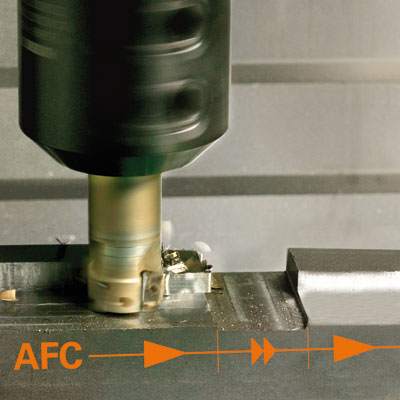

AFC – Adaptive Feed Control

The adaptative regulation of the advance optimises the advance of path in function of the power of the cabezal and of other data of the process. Precisely when, during the mechanised, vary the conditions of cutting had to, for example, to depths of cut fluctuantes, wear of the tool or to fluctuations of the hardness of the material, the function AFC provides always the maximum possible advance, increasing like this the efficiency.

The application is simple: Before the mechanised can establish in a table value maximum limit and minima for the power of the cabezal. For this, the TNC registers during a cut of learning the maximum power of cabezal that appears. The adaptative regulation of the advance compares then of permanent form the power of the cabezal with the speed of advance, and tries to keep the maximum power of the cabezal during all the time of mechanised.

Thanks to the function AFC the time of mechanised reduces of significant form, since, in zones of mechanised with lower volume of material, the numerical control increases the advance of adaptative form. At the same time it monitors the tool. The numerical control reduces automatically the advance when a tool desafila, since, in this case, the power of the cabezal increases. The option AFC takes care besides the mechanics of the machine, because the numerical control adjusts the advance of adaptative form when exceeding the maximum power of the cabezal. Like this it protects of effective form the cabezal main in front of overload.

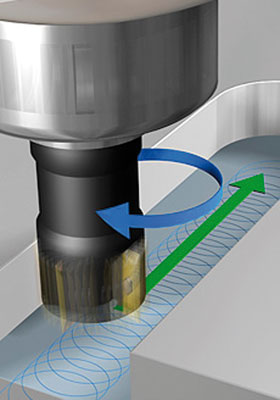

Milling trocoidal

The cycle of the TNC ‘Milling trocoidal' accelerates significantly the mechanised of desbaste of slots with outlines any one. In this cycle superimpose a movement circulate of the tool with a movement of linear advance. The cycle allows that it was started material along the total length of a cylindrical strawberry. Thanks to the ‘peeled' of the material can work with a big depth and a high speed of cutting. Thanks to the penetration in shape circulate in the material, the radial strengths that act on the tool are reduced. This takes care the mechanics of the machine and avoids the apparition of vibrations.

Important gain of time thanks to the combination of milling trocoidal and AFC

Each one of these solutions offers by himself same decisive improvements of the process of mechanised. But also they can combine between himself. For this put special emphasis in that the dynamic behaviour of the machine do not see mermado. Only like this it can guarantee a mechanised efficient with the corresponding precision.

When it combines the milling trocoidal with the adaptative regulation of the advance AFC can have a significant plus of efficiency. Since the tool is driven inside the material through a circular path, in a part of this path circulate does not take place any penetration. In this situation, AFC displaces the tool to a significantly greater advance. Of this form achieves an enormous gain of time during the process of mechanised with the cycle of Heidenhain.

An effective combination of software for a profitable mechanised heavy

The measure for mechanised of desbaste efficient gives it a high volume of start of material along the time. With the options of software of the numerical controls TNC of Heidenhain, englobadas under the general concept of ‘Dynamic Efficiency', these mechanised can maximizarse of form especially effective. With the combination of a simple operation of the functions, a reduced solicitación mechanical of tool and machine, as well as a high precision of mechanised, the numerical controls of Heidenhain show his high requirement concerning a desbaste more efficient.