Interview to Darío González, manager of Indaero Tecnograb

Currently Indaero provides 3 product lines, such as Darío González, Manager of the company, explains: Interior plates (control panels, cabin panels, labels other signs); covers and cases of protection for the outside fuselage; and structural metal and thermoplastic parts. As subcontractor located in Alcalá de Guadaíra, Seville, concentrates most of its products in Airbus, selling much of his local level supply chain companies and with the European Consortium EADS as a main client. However, this last year they have also begun to commercialize products in Poland and Austria "and have project exhibit in Portugal and Germany in the coming months," said.

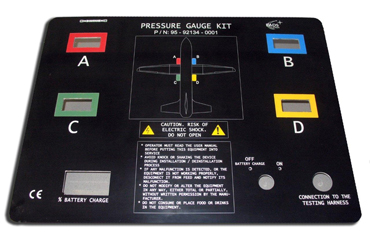

Also, Indaero has recently signed three contracts for the design and supply of equipment for aircraft such as the C-295, A400M and the A330-MRTT currently, they are working on the design of a container detachable and modular low weight to the cargo air transport using robot arm laser welding technology. "This project we are collaborating with IAT (Andalusian Institute of technology) and the Unilaser company".

Darío González explains that to participate in aeronautical projects one of the possible routes is "be experienced provider and the customer having confidence in your work. As it is the case of Indaero, with an experience of over 40 years as a provider of the EADS Consortium".

Certification, a prerequisite for working in this sector

As a provider for the aeronautical sector, Indaero has had to comply with "two essential requirements such as be certified under the quality system EN9100 aeronautical and maintain a manufacturing cost-adjusted according to the standards of Lean Manufacturing'." The third requirement would be trained to carry out a comprehensive manufacture of the product and the fourth, having well trained staff." For this reason, Indaero is certified under the EN9100:2009 standard and works continuously to adapt to Lean Manufacturing. In the past three years they have gone from being "simple manufacturers already designed products. to partner of Airbus in development of equipment Starting projects from design, manufacture, purchase of raw materials, Assembly and performing test to ensure compliance with the technical requirements".

This development process begins with meetings with the customer to meet the technical requirements, as well as the expectations of the customer in terms of quality, deadlines and scope of service. "The complex projects require planning meetings to coordinate resources and ensure compliance with the delivery date. At this point, we involve the departments of quality, human resources, design, purchasing, engineering and finance. Evaluate the risks that exist and which would put at risk the compliance of quality and delivery", explains Darío González.

"Generally the work begins making purchases of raw materials and components. The design of the equipment takes us between 1 and 3 months. We make meetings to define the product and once the client agrees and the input data have been revised, is to manufacture a prototype that will be validated on the plane. This prototype is subjected to tests internally or in laboratories to ensure compliance with the technical requirements. The Engineering Department then begins to make all technical documentation, orders of production, plans, technical manuals, 3D models, etc. "." The manufacturing process includes from the purchase of raw materials and components, the machining, forming, painting and Assembly.

How to participate in aeronautical projects?

According to Darío González, there are several possible ways: "be experienced provider and the customer having confidence in your work". This is the case of Indaero, with an experience of over 40 years as a provider of the EADS Consortium. Another option is to "have a product or service, highly competitive, which significantly improves the costs. This process may be the slowest since the validation process is long. In the aeronautical sector should ensure that cost reduction does not alter the quality and does not generate risks".

Thirdly, have a product or service very advanced technologically. "There are Andalusian companies that have positioned themselves as direct suppliers of Airbus in the field of avionics and software systems in a short time," he adds. And, finally, "to be a company with a very high investment capacity and ability to lead key projects".

Advances in new materials are changing the challenges for companies working for the sector of Aeronautics and the future "through those polymers (thermoplastics and composites) to respect the environment".

Be well equipped technologically is one of the prerequisites for the projects with guarantees. For this reason, in Indaero they have very different machinery for machining, forming, recantear, etch, paint and assemble as well as design, 3D and management ERP software. In this sense, Darío González says that "investments should be continuous and up-to-date technologically. Investment in quality and training must also be continuous".

The environment and Aeronautics

Advances in new materials are changing the challenges for companies that work for the aeronautical sector, land won those polymers (thermoplastics and composites) to respect the environment. "Also the smart materials, i.e. materials that adapt their behavior according to external conditions and recycled materials". In this last aspect, Indaero is working on a project of r & d together other 5 companies and 3 technology centres for the use of waste from the sea in the manufacture of coatings that could apply both to the aeronautical sector and construction.

Another trend is weight reduction, lower consumption and, as a result, fuel economy. A weight saving that begins in the departments of engineering, and the trend is to use materials and advanced manufacturing processes. As a result, "machining are complex and little stable materials and machining centers 5-axes, special tools, modification of manufacturing strategies is needed," it aims. "It should also be machined carbon fiber with the inconveniences and specialization that this process needs. New adhesives that substitute other bonding systems being used. It is very important to stay up to date on knowledge".