' Fiber placement' high speed on large and complex structures

Dave Regiec, Redex-Andantex USA Inc.

Peter Vögeli, ElectroImpact Inc.

22/07/2013Reduce the weight of an aircraft is essential for maximizar the efficiency in the use of fuel. No only it results important in terms of reduction of costs, but, taking into account that it expects that the aeroplanes visit distances every time greater in the future, have more capacity results fundamental. The high relation resistance/weigh of the fibre of carbon is one of the main innovations of the actuality, but to reach indexes of production elevated needs machinery extremely complex. Electroimpact Has developed an extraordinary solution that offers a speed of 50 metres by minute in the automatic placing of the fibre of carbon. It treats of a system of control very sophisticated with systems of accionamientos highly stable and precise. Andantex USES, subsidiary of the group

Electroimpact Is a young company of engineering whose mission is to turn into the main provider of equipment of automation for the world-wide aeronautical sector component manufacturing sector component manufacturing industry. Electroimpact Has developed the technology of Placing Automated of Fibre (Automated Fiber Placement or AFP), that allows to cut and apply stravel of fibre of carbon (tow) with tolerances of placing for the final customer of until 2.000 inches by minute on bent and complex surfaces. Each laminado can carry out of form totally bisteeringal and the operario can control the speed of advance without that this repercuta in the precision of the cut. Electroimpact Has big experience in the supply of solutions of automation and mechanised industrial. The strong point of the company is the integration of the automation and the mechanised in solutions of synergistic production. His equipment of engineers of high qualification endow to the company of a big flexibility to assume several projects on a large scale simultaneously. This only approach has done to grow to Electroimpact until arriving to turn into the elder integrador of lines of setting of aircraft of all the world. His wallet of customers includes manufacturers of commercial and military aviation of all the world.

Electrimpact customer profile is a large manufacturer of components of aerospace of USA that manufactures airframe, soffit, composite components and wings for the aircraft industry. The company headquarters is located in Wichita, Kansas, the World Capital of the air, but we also work in Tulsa and McAlester, Oklahoma, Prestwick, Scotland and Samlesbury, England.

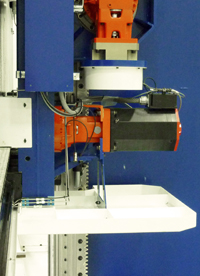

Automated placement of fibres (AFP) machine is designed to manufacture large commercial aircraft structures and has fast modular heads, with a speed of automatic change of 30 seconds. To manufacture these large pieces of the aircraft, the structure of the machine that controls the movement of the X, and Z-the head of the fiber (mill or bridge designs) laying has a weight of about 350,000 pounds (175 tons) and rushes to 0.2 g. The carbon fiber tow (narrow tapes impregnated carbon fiber) are placed on parts with multiple forms (wide strips of ¼ or 1/8 inch in areas of high contour or ½ inch or less in areas of low contour) to achieve the maximum possible productivity: is a 100% free torque, 100% operation without breakage of joints and fully bi-directional.

Detail of the head of the Fiber Placement.

The X axis, and and Z-drum rotation work together so the carbon fiber can follow the outline of the piece that is manufacturing. Carbon Fiber Ribbons are placed on the tool which is machined with the final form of the same. In addition, carbon fiber has to be applied on different layers and different directions to optimize the strength of the final part. The aim is that carbon fiber has a very strong tension so that all loads acting on the workpiece can be supported in tension.

The linear routes can be short, ~ 2 meters (6.6 feet) on the X axis, or move along around the X axis, which has ~ 30 meters (98.4 feet) in length. Travel depends on the piece that you manufacture.

An advanced control system

Cutting machine system has been subjected to a complete reengineering and optimized feed system, tape travel and the Creel of the head of the fiber placement system. The system of control of the machine reached the cut according to the specifications, as well as the application to flight exceeding 2000 inches per minute. Specifically, from the cutting of high speed flight emerged a number of issues. With a speed of extended 2000 inch per minute (R) and the tolerance of placement at the end of the cutting of +/-0.050 "(or 0.10 total [k]), the opportunity in terms of time is as follows:

T = (60 * k) / R (seconds) or,

T = (60 * 0.10) / 2000T = 0.003 seconds.

Said of another way, to 2.000 inches by minute, 1 millisecond equivale to 0,033 inches of trip of the strip. This shows that the total precision and the repetibilidad of the system of cut have to be very upper to the speed of typical cycle of the CNC (4-8 ms). The repetibilidad of the individual components (like actuators, valves, etc.) has to be in the rank of the sub-milliseconds or even improve it. Besides, the system to signpost a cut has to have a resolution of sub-milliseconds.

Electroimpact has developed a cutting mechanism of high speed that allows cutting at speeds high cutting times that in total they do not exceed 1 millisecond. In addition, the system has low variability, making accurate placement of the tape and repeatable, even with speeds of extended very high. Factors that affect cutting and application to flight time are, among others, the implementation of the programme, the reaction of the output module, the action of the solenoid valve, the air flow and the reactions of inertia of the mechanisms of action. All of these factors delayed the execution of a court or application with respect to the nominal signal. If this delay is predictable and repeatable, cutting time can be compensated. In any case, these delays must be reduced whenever possible. Thanks to the many developments and tests at Electroimpact, the variability of delay, both the advance and cutting, has reduced below 1 millisecond, achieving a great precision in the placement at the end of the Court and at the beginning of the sequence.

Generally, conventional and the PLC or CNC controllers work with "cycle time" which is usually measured in milliseconds. The products are powered once per cycle, so the temporal resolution is limited to the cycle time. If a 1 millisecond delay gives as a result a final placement of 0.033 "error 2000" / min, introducing an error of only 1 millisecond control is not acceptable in the courts or applications to high-speed flight. An extremely precise integration of motion control of the CNC and the timing of the Court and application commands is needed to reduce to a minimum delays in the time of control.

Electroimpact has decided to use the 'Customer Board' Fanuc, a system that allows us to interpolate the Court and the application to profile in movement to the level of command of speed of CNC. This is the first time that used the 'customer board' outside Japan. Electroimpact collaborated closely with Fanuc to implement specific features for applications of the AFP. Temporary delays due to control are in the range of milliseconds, which eliminates effectively delays at the time of control as a source of error in the Court and the enforcement.

Electroimpact customers have recognized that within your standard software package, which updated and maintained regularly, they need a programming software developed by a supplier recognised within the industry. More than 2 years, Electroimpact has been CGTech non-exclusive partner in the development of software programming for AFP called Vericut Composite Programming and Simulation Suite.

Andantex exclusive solution

For Electroimpact, Andantex USA, subsidiary of Redex in the United States, should deal with complex constraints: combine high speed, great weight machines and very complex movements with frequent in all directions and consecutive accelerations.

"We chose Redex Andantex drives because no one else can manufacture a case of accuracy with that pair and force drive," explains Peter Vogeli, Chief Engineer of ElectroImpact, Inc.

The first difficulty is to remove excessive slack. The drive systems TwinDrive rack and pinion are made up of 2 servorreductores planetary electrically coupled and mounted in parallel. Preload system eliminates slack and allows that the servo-sistema can accurately control the position of the control shaft.

The second issue is to ensure that there is maximum rigidity to provide a perfect repeatability despite frequent cycles of acceleration. Thanks to a drive shaft with a pinion integrated in the planetary system of the gearbox and reinforced with large diameter bearings Gets a highly rigid in all directions. This unique concept of Redex Andantex offers a few features in terms of torsional stiffness that are among the best in the market but, above all, offers rigidity at other levels (radial and axial); This normally allows working with rates of acceleration or weight that can reach double those of other solutions. The diameter of the pinion is optimized to ensure the best ratio between the transmitted torque and linear stiffness (view from the zipper). The bearing arrangement consists of two conical, preloaded roller bearings and with a King size. This arrangement of the bearings is designed to withstand pinion close as possible to the applied force and the only thing that separates the output bearing pinion preload bolt/nut thickness. This special design offers a significant reduction in radial deviation refers to, which, accounting for 60% of global deviation, usually not be tackled properly with other systems.

Andantex USA is a global supplier of linear and rotary axes and racks and pinions gear.

Redex Andantex drives are installed in all the axes of the machine, being therefore responsible for the behaviour of machine Assembly.

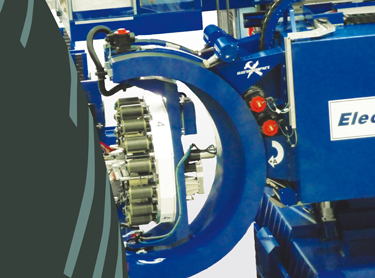

The axis of rotation of the drum acciona the tool on which goes to plant the fibre of carbon. This tool is used to to be manufactured in invar, that is a type of steel with a thermal sensors dilatation very reduced. This is important, since once manufactured the piece all the group plants in an autoclave and hornea to guarantee that the fibre of carbon impregnated purchases his definite state. After this, the tool extracts and the remaining piece is of fibre of carbon in his whole. 4 reductores Redex Andantex type KRP size 6 allow a precise rotation.

- Maximum speed of rotation: 81 RPM

- nominal Speed of rotation: 25 RPM

- Pair engine of beak: 6.600 NM

- Configuration: (2) accionamientos TwinDrive / axis

View of the head of the Fiber Placement.

The X axis is equipped with 4 planetary reducers KRP's size 6, which is the maximum available size in the range of Redex Andantex. These reducers are complemented with two zippers on a stretch of 35 m long.

- Linear speed = 51 M/min. (2000 inch/min)

- Mass = 160 tons (175 American tons)

- Acceleration = 0.2 g

- Configuration: (2) drives TwinDrive / shaft

Shaft and account with two planetary gearboxes SRP in a drive TwinDrive configuration. They are mounted on a rack of 5.5 m.

- Linear speed = 53 M/min. (2450 inch/min)

- Mass = 14.3 tons (15.7 tons American)

- Acceleration = 0.2 g

- Configuration: (1) drive TwinDrive / shaft

«For the secondary feedback of the encoder on the X axes e and Electroimpact also uses the PDP or» pinion preloaded to operate the encoder directly from the zipper with zero clearance. This cost-effective solution represents the first generation of 'double preloaded pinion' in planetary reducer for applications of high-precision rack and pinion. The PDP is made up of two ground pine nuts, with a width of half-zip each, and which is connected through a patented system of preload to eliminate the clearance between the pinion and the rack gear. The innovative concept of the PDP provides a feedback of the encoder directly from the rack, which offers a great positioning accuracy and repeatability at very competitive prices.

- MOD. Axis x. 10, Circ. = 500 mm

- MOD. Shaft and. 5, Circ. = 250 mm

Andantex also supplied modules 10 & 5 coil zipper, hardened and ground for the X axis and with pinions lubricated polyurethane to lubricate zippers and pine nuts automatically. The zips are offered in sections of 1 or 2 meters. Thus, Andantex has been the official supplier of all the mechanical parts between the actuator and the shaft.

At the end, positioning accuracy is equivalent to the precision of the cut (+/-0.05 ") at maximum speed. Shaft powered by Redex Andantex reducers must be even greater than this value accuracy, since all work together to create a complex shape. «We can calculate that the precision of the axes X, and Z is the positioning precision 1/10 or +/-0.005 "(0.0125 mm)», explains Dave REGIEC, Chief projects Andantex.

Redex Andantex, headquartered in Ferrieres, France, employs 320 people and has three production sites in Europe and North America. More than 75% of their sales are generated outside France. Technological progress, commitment to quality and exceptional technical support are the key values of Redex Andantex.