Renishaw offers process control solutions to improve production in the 2013 EMO

In the fair EMO Hannover 2013, Renishaw presents (in Hall 6, booth B38) a range of solutions for process control designed to meet the growing demand for increased production, from new technologies for calibrated machines before the process up to the measurement on machine and in post-processing, out of machine.

To display the novelties presented at the fair, the firm invited to the specialized press at its facilities in Gavà (Barcelona). Ali, Víctor Escobar, CEO, Renishaw Ibérica, did a review of solutions that visitors can see in the fair. "The current industry demand reliable products that meet the needs of enterprises, calta alidad, quick-fix solutions and constant innovation," he said during the presentation. Demands of Renishaw works to offer its customers every day. "The world of dimensional metrology is in almost all aspects of production, products of our daily lives, but we don't realize," he explained. "Having a metrology system allows, even a small workshop, add value to their products, which results in a higher quality final." Aware that their solutions can help make the most of machine tools, ensuring that they maintain the characteristics and initial tolerances, allowing measure even free forms, Víctor Escobar presented the main novelties that the EMO attendees can see.

Scanning system for analogue high speed Sprint contact

The system of exploration by contact, completely renovated, Renishaw introduces completely new opportunities for process control for CNC machine tools of high value. The Sprint system incorporates a new generation of analog exploration technologies in machine, which will result in a profound change in the advantages of process control, and allow you to quickly and accurately capture profile data and forms prismatic components and complex 3D shapes.

Víctor Escobar also said that during the EMO Renishaw it attached special importance to this section, dedicating a special space and holding meetings with manufacturers. "Today we have three projects key in hand related to the aeronautical sector," he added.

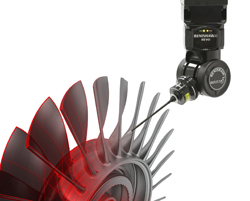

In this sense, the Sprint system includes performance unprecedented for restorations of blades. For multi-tasking machining applications, exploration in Sprint machine tool system offers the user a completely new process control functions, including cycles of diameters repeatable measurement. Other additional functions offered by the Sprint system is the quick check of the linear and rotary axes State of a CNC machine tools in seconds, allowing you to implement a regime of monitoring of daily machine with little operator intervention.

Complete integrated package of measurement of high-performance blades and analysis tools

Renishaw highlights at the EMO exhibition emerging family of product development of hardware and software for high performance for coordinate measuring machines, designed expressly to facilitate the measurement and manufacture of aerospace propellers. All products complement the award-winning Revo 5-axis measurement system and include the planning software APEXBlade for helical scan Revo and programming DMIS, aerodynamic analysis Modus for calculating and reporting section of fan blades and aerodynamic characteristics, and SurfitBlade profiles, to facilitate the reverse engineering of the complete aerodynamic system.

Revo can measure complete turbine blades, is a software that allows you to interpret the data and draw the conclusions necessary to perform the work, reducing errors and optimizing work time", said Escobar. Thanks to this system can measure unlimited number of sections, accessing information from around the blade. "It represents an Automation up to the end of the measuring process, which until now was to point to point". In addition, the head may be attached a roughness Tester instead of the tracer point.

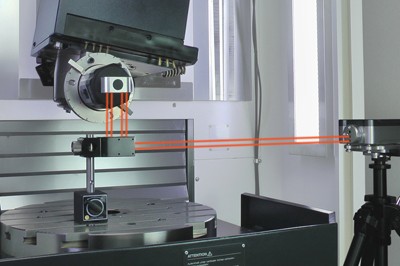

Encoder laser HS20

After a thorough process of updating, EMO presents "the direct evolution of the encoder laser long-range HS10 which, with a range up to 60 meters, has found multiple applications in machine tools in large size for the aerospace sector. In addition, being a direct replacement, the HS20 doesn't install problem for current users". The product has been fully revised Interior and is equipped with many of the proven components of the current calibration XL-80 of Renishaw laser. Printed circuit uses the latest technology of surface (manufactured in the facilities of Renishaw) mounting to facilitate more solidity and reliability.

New advances in the knowledge of the performance of rotary shafts

Renishaw has expanded solutions for performance verification of alignment and positioning of the rotary axes of machine tools with the launch of the new software with external mount XR20-W ("where the W means wireless, cable-free") for the rotary axis gauge. Especially useful for those using five-axis machine tools, the new software allows the successful XR20-W system used to measure the accuracy of Rotary positioning of an axis in many configurations of machine tools of five-axis, in which often the XR20-W system not can be in the center of rotation.

New processes for Equator gauge monitoring software

For those users of offline measurement systems, workshop user interface now includes a new window of monitoring processes for caliber Renishaw Equator system. The window immediately shows the measurement results of the areas inspected in a bar graph display. It also shows the history of measurement of each surface to observe the trends of processes. The process of remastering of the system can be managed now based on the limits of temperature, the number of pieces or the time elapsed since the last mastering. "The Equator allows measuring in situ beside the machine, without moving the part of the room, which gives greater speed to the process," explained the director of Renishaw Ibérica. In this regard, he added that Equator is a system designed to make it easy to use, "and flexible position which is programmable as any coordinate measuring system, allowing to work any part". In addition, he explained that "novelty is software, with more applications and data control for the preparation of reports, among others".

Growing and investing in r & d

During the press conference, Víctor Escobar also explained the plans for the future and the ambitions of the company, which is still growing. Renishaw currently has all its production plants in Great Britain but one, in India, where manufactured concrete products. Within its expansion plans describes the acquisition of industrial space in South Wales, about 20,000 square meters of production plant, to comply with the company's growth plans. There they displace production of machines dedicated to the additive manufacturing, leaving r & d in North Wales, where are today. Note that Renishaw is a company that dedicates special attention to product innovation, investing in it between 17 and 19% of its turnover.

Real absolute Optical Encoder with Siemens Drive-CLiQ interface

Siemens Drive-CLiQ is a comprehensive and innovative communications interface used to connect the encoder and measuring systems direct to the Sinumerik, Sinamics units components. Through the optical absolute encoder real Resolute interface Dive-CliQ, manufacturers of machines can get greater performance and more reliability. Attendees at the fair can check how this product determines the position immediately after switch on, therefore, is especially suitable for high performance lathe spindles and DDR direct drive engines, which require the highest levels of accuracy and completeness in the control of movement.

Mounting of Resolute.

Renishaw acquires LBC Laser Bearbeitungs Center GmbH

Renishaw, in an agreement of transfer of assets, has acquired the template from LBC Laser Bearbeitungs Center GmbH, pioneer in the field of manufacturing and the business contribution of material for the creation of moulds and tools. EMO 2013 attendees, shall also verify that the agreement will allow Renishaw, leading supplier of Foundry laser systems, offer of contribution of material making additional services, such as design, simulation and manufacturing contract from metal prototypes and production parts.