The 'intelligent production', central axis of EMO Hannover 2013

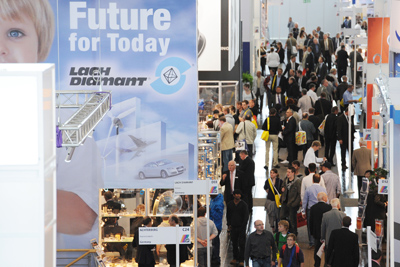

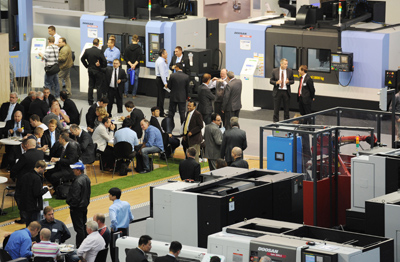

The EMO Hannover 2013, fair global reference for the processing of metal, opens its doors from 16 to 21 September under the slogan ' Intelligence in production'. In it, exhibitors from around the world present solutions in response to the challenges of an international industry in the twenty-first century.

In a globalized economy, ' Intelligence in production' offers the possibility to satisfy the most different customers at different locations where production takes place. In the most important international platform for the technique of production, the EMO Hannover, these smart solutions are presented. "All users of production techniques currently being faced in the whole world challenges", says Wilfried Schäfer, Secretary general of the organizing of the EMO, the Association of German machine tool manufacturers (VDW). Subjected to enormous pressure on costs, high requirements in terms of efficiency and respect for the environment, the production also has to be conceived in the future with economic criteria. "Experts in production around the world seek answers to these challenges and therefore await with great interest the celebration of the EMO Hannover 2013," added Schafer. The exhibitors of the EMO that support their customers to remain competitive in the global market, can get it: ' Intelligence in production' is the key to this.

In the latest edition of the EMO exhibition, held in the year 2011, more than 2,000 companies, of which 60% came not from Germany were exposed.

Partners in the global market

In the past 20 years, the international consumption of machine tools is has more than doubled. Now while most of machine tool manufacturers and their customers act globally. More than half of the international machine tool production is exported to other countries. Around one-fifth of all machines that are needed in the world come from Europe, which supplies its products to more than 90 countries.

This fact creates large possibilities and represents great potential for those manufacturers who are able to attend special wishes that require regional characteristics. So, it is necessary to provide products, services, support and partners for different markets, organised in an intelligent manner. It is globally satisfying the desires of customers through the corresponding know-how, a wide technological vision and a marked ability in the study of the processes. All supporting usually a strong pressure of costs and competitive offerings.

"Customers are looking for competent partners in the global market", States Wilfried Schäfer. To present the appropriate technical offer requires, therefore, a global presence with the corresponding possibility of dialogue, a reliable service throughout the world and a full proposal for services, being able to reach even up to in situ production. The EMO Hannover 2013 expose around 2,000 companies around the world who report on their ability to act in the global market.

The production engineering Summit meeting

"The EMO is the showcase for the world. "Here are all those that have relationship with the machine tool: executives with decision making capacity in most sectors of the industry, pioneers of the market in the technique of production, representatives of the world of science and politics". So insurance is displayed Wilfried Schäfer about the fair, convinced that "will provide decisive impulses for the manufacture in the coming years".

In the last edition held in the year 2011, were exposed in the EMO over 2,000 companies. 60% Of them came not from Germany but from 40 different countries. And only Eastern Europe more than 68 exhibitors were counted. "Participation at the EMO Hannover is an initiative that is mandatory for any machine tool manufacturer who wants to do business internationally," he says emphatically. In the same way, users of machine tools are in Hanover production engineering seeking as well as the appropriate partners. And this is true both for manufacturers of small series and who manufactured on a large scale.

And it is that the EMO is equally attractive for exhibitors and visitors. Its size, amounting to about 180 in the last edition 000 square meters of net exhibition area, guarantees all visitors get a complete overview about the technique of producing intelligent in the fields of machine tools cutting and molding, manufacturing systems, precision tools, technical measurement, automated flow of material, CAx technologies, systems of control and regulation as well as accessories. The strict distribution of the offer within the fair by nuclei of products guarantees in addition to the professional visitor navigate easily and quickly to find everything you are looking for.

68 Spanish manufacturers attend the EMO from the hand of AFM

Up to 68 manufacturers Spanish companies of maquinas‐herramienta, components, tools, and accessories will come to this new appointment in the sector with an impressive technological display and occupying more than 7,000 square meters. Since 1975, year of first edition, AFM, Advanced Manufacturing Technologies, the industry association, It organizes the Group presence of Spanish manufacturers that made a major investment to go with its more advanced solutions. José Ignacio Torrecilla, President of AFM, explains that "the huge effort that made our companies to go to the EMO is reflected in high added value solutions aimed at specific applications, high-performance machines and precision and components, tools and high-end accessories complete our production offer as a country".

Spain is the sixth country in number of exhibiting companies, after Germany, Italy Japan, Taiwan and Switzerland. Turret emphasizes that the EMO is a milestone for the industry: "hope the EMO mark a change of trend is the beginning of a strong recovery of the global demand, after a few months of relative slowdown. Experts predict an increase of 2% in global consumption of maquinas‐herramienta in 2013, which by 2014 will reach 10%. Is estimated that the main target of the world maquina‐herramienta sectors (automotive, metal, electrical engineering, precision engineering and optics, medical technology, aerospace, railway and naval, fundamentally) will invest 6% more in 2013, figure to be doubled in the year 2014. These forecasts invites us to believe will present good opportunities for our companies, that as we can now leverage if we keep winning in technology, internationalization and trained people. It will also be essential, as we have been stressing, increase its dimension".

Innovation for production in the world

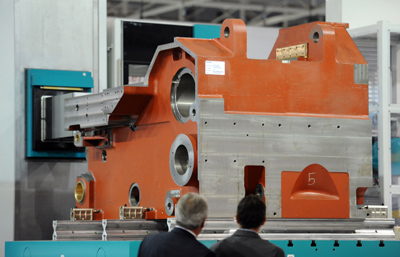

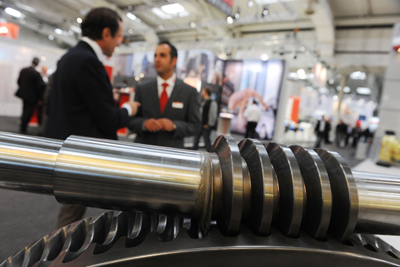

Efficiency, quality, flexibility and availability are the foundations of the success of the user of machine tools, regardless of the place in which manufactures. Often, minimum benefits in costs are decisive at the time that the client uses to order. These benefits are achieved with intelligent production techniques.

In this regard, figure always in the foreground the continuous improvement of concepts on machines, control technology as well as the software, tools, and processes. With continuing innovations in all fields is achieved develop the functionality of intelligent production systems.

The demands currently placed customers like, for example, changing series, countless variants on products or requirements in terms of the sustainability of production, additionally stimulate the creation of innovations. The solution of these complex tasks increase communication needs. The availability of simultaneous large amounts of complex data in all fields of the enterprise, from development and construction to production planning and control orders, require the need for a completely free flow of data. For this reason, modern and efficient companies are responsible for have fluid communication systems, using the right software for planning, control and verification. And modern production systems must be modified always in combination with the TI worldwide.

Support smart operators working on machines

Differentiate themselves in the marketplace by the high-tech is not enough for a company dedicated to the manufacturing technique that found clients in varied conditions. "In general, operators working on the machines are facing increasingly complex requirements", says Schafer. The quality assurance, documentation, monitoring and maintenance of the machine or the achievement of an efficient performance from the point of view energy are only some of the concepts that must be taken into account here.

' Intelligence in production' helps the operator working on the machine to carry out reliably all the corresponding tasks. The tools to do this can be, among others, control by Internet through systems of diagnosis, Teleservice or innovative concepts of hotline. On the other hand, specific concepts of learning are responsible for providing to the customer, also in the long run, mastering the techniques required.

The adaptation of these intelligent functions of operator assistance in different markets, by the manufacturer or in cooperation with suppliers in situ, constitutes a valuable argument against the competition.

Innovations for the production of the future

Since the first edition of this event, held in the year 1975 EMO Hannover 2013 has been expanding and confirming their reputation as the largest and most important forum for innovations in the world in the field of metal processing. "Technical progress is not an end in itself but that it is powered by the global social and economic demands", manifesta Wilfried Schäfer, adding that, among others, are global trends such as urbanization and expansion of infrastructures, mobility, energy, food and health which have led us to the technical progress, the same thing has happened with the problems that arise on a daily basis in the production. "In order to survive, all industrial enterprises have to study current trends, predict the future a little and remove it the appropriate consequences to develop their own initiative in terms of innovations and products of its own." Exhibitors at EMO Hannover 2013 provide for this information, help and assessments by experts. The global developments in society, in the economy and in the field of technology provide trends that are reflected in the manufacturing technique.

The global Megatrends driving the technical developments

Since 2009 live worldwide more people in cities than in the field and this trend will increase in the future. A modern infrastructure and a powerful communication networks have to take care of, nevertheless, keep the quality of life. In growing cities bring with them new technologies of construction in which more and more requiring more new materials that are supplied as prefabricated. On the other hand, the modern factories are inevitably built in areas with increasing population density. For this reason they have to meet special requirements with regard to emissions, consumption of resources and space.

One of the biggest challenges lies in meeting the needs of energy, growing, prices are bearable and not contaminable form. To do this required environmental techniques, intelligent and effective. Only with the more modern and precise manufacturing processes can optimize results and provide an efficient technique. New approaches for obtaining energy from renewable sources must be completed with solutions to achieve energy savings. Precisely here lies the requirements that have to fulfill OEMs. Blue competence, initiative in the field of the sustainability of the European machine tool sector provides other examples of energy-efficient solutions in industrial production. "At EMO Hannover 2013 will be discussed so widely within the framework of Congress 'Produce intelligently'", says Schafer. Additionally held a special exhibition in which the exhibitors of the EMO presented their solutions in the field of energy efficiency.

The increase of the world population and the ever-increasing level of well-being have as a consequence the appearance of numerous requirements. Thus, for example, is to ensure food and medical care. The availability of water and food is a question related to the production, the manufacture of products, packaging and distribution. The technical solutions of modern agriculture, the manufacture of food products, packaging, wider logistics logical chains, the creation of networks of maritime transport, transport by rail and air as well as software programs for the optimization of capabilities indicate the way to follow and condition already in production bases the necessity of efficient technologies. Precisely machine tools enable other sectors of construction machinery and equipment to cope with the changing demands with the implementation of modern and efficient solutions.

The improvement of the standard of living brings directly the increase in the demands of the population that is evident in the high demand for individual mobility as well as the desire for more products and services. On the opposite side, are increasingly scarce natural resources, the rise in prices of raw materials and one growing awareness with issues related to the environment and climate change. Therefore effective production processes can make possible the manufacture of products of high technology in large series and at a reasonable cost. At the same time, however, it has to prevent waste and get some life cycles of products increasingly shorter as well as an individualized manufacturing.

With demographic change and the ageing population emerge new aspects to take into account. On the one hand, increases the demand for health care quality that is economically bearable. Also in this field there are, among others, technical solutions that promote progress. Automation, new imaging techniques, implants and prostheses, apparatus for self-diagnosis or monitoring by means of data transmission are some of the key concepts in this context. On the other hand, precisely the industrial sector has to adapt to the conditions of a workforce with increasingly higher ages. It is offset by technical solutions deficits due to age, for example, the decrease in the body capacity, lower auditory and visual capacity, or casualties at work due to the increase in diseases.

Worldwide, companies try to find solutions to the problems they bring with them these mega-trends and avoid what effects they have for your business. The core of this problem vary depending on individual markets. In many cases significant advances are achieved in these fields and often with technical developments and products which are industrially manufactured. "Machine tool, as key technology for industrial action, is involved in all parts in the solution of the current and future challenges, ensuring progress in many fields", States Wilfried Schäfer.

Mega trends also modifying industrial production

In machines, tools and components are also new challenges. Aspects such as, among others, efficiency, sustainability, communication and networking, new raw materials, flexibility, quality, new concepts of products also here play an important role. The efficacy of the machines is to measure in relation to the necessary use of resources for the manufacture of a product. Productivity is essential in this regard. A more efficient components such as propulsion and hydraulic equipment, high level of efficiency tools or optimised processes complemented with an intelligent control make it possible to achieve a rational manufacturing. Thus the existing potentials of savings can put into operation throughout the chain of creation of added value. Coupled with a growing level of automation as, for example, for the management of parts and powered machine, you can get some attractive offers for the entire life of a machine or equipment.

The quality of the manufactured product has to overcome the existing discrepancy between individual consumption needs that are growing rapidly and natural resources available to do so. More goods and products are not only demanded that the tendency is also to similar products manufactured in series products with individual characteristics. Thanks to modern manufacturing processes, can occur nowadays large number of parts using increasingly less material and resources, without losing sight of individual variants in addition. Thus, for example, demand has increased for hip implants. Modern digital image transmission processes make it possible to further the achievement of a prosthesis that is individualized for each patient. For the manufacturing process, this means that only a part of a piece has the same geometry and therefore the machines should always be constantly reprogrammed.

The use of high-precision machine tools improves also the technical functions as, for example, to obtain surfaces of great accuracy with small tolerances. This is can, for example, optimize the gaps in motors, generators or turbines. With the performance achieved in this way large levels of savings can be achieved above all where the production process has a low degree of efficiency. Intelligent production planning means to avoid media wastage and, in this sense, you can, for example, enjoy the heat emitted by the machines for heating office buildings.

"In all aspects described, the intelligence of future production systems is a central theme," says Schäfer. According to him, the intelligence works in two directions. On the one hand, efficient components can be combined into networks and optimized. The role of predecessors who have smartphones, so-called smartphones, combined with autoorganizables not centralized networks, is also reflected in the industry. Components and assemblies of machines provide their own characteristics and optimal parameters of operation, connect themselves with upper level controls and are able to start working in a minimum period of time without the need for manual intervention. On the other hand, it increases the complexity of the systems used precisely because he is not available centrally the information. Therefore, persons who have been trained to serve the machine, carry out maintenance or schedule production must be able to perfectly dominate its operation. The key concepts in this sense are the intuitive programming of machines or decentralized diagnosis.

A parallel program devoted to the trends in production engineering

The EMO Hannover is surely the most important meeting for all stakeholders in the sector of processing of metal, both manufacturers and users. But it is also traditionally the innovations Forum and the event in which they are established trends. This explains the full and varied parallel programme prepared for this year's Edition:

- Congress 'Produce smarter' EMO

According to the reference of the EMO topic ' Intelligence in Production', the VDMA organise within the series ' producing smarter ' 2013. In the Centre of the attention of this event, under the title ' Inspired by technology' are the topics: innovative power, flexibility, and technological know-how which are for the companies manufacturers important success factors in global competition. Top international executives from the world of the technique of production and auxiliary industry, inform here about their strategies. In three different forums will be discussed also about excellence: lean production and flexible creation of value-added chains; efficiency: sustainable and environmentally-friendly production with natural resources; Intelligence: smart factories through industry 4.0. This program involving speakers of great prestige comes complete with tours of the fair devoted to specific topics.

- Blue compétence in favour of energy efficiency in production

Sustainability is today one of the most important premises to achieve positive development in politics, economy and research. Politicians, industry and the University have understood it as well and have promoted the change. However, it is necessary to insist on this to get a so paradigmatic transformation. This has been created 'Blue Competence - Engineering a better world', an initiative of the European industry of machine tool and the German engineering industry sector. For the second time will be in the EMO Hannover, complementing the Conference being held in the framework of the Congress 'Produce smarter', a stand dedicated to the Blue Competence which especially shows products and solutions for an energy-efficient production.

According to the reference of the EMO topic ' Intelligence in Production', the VDMA organise within the series ' producing smarter ' 2013.

- EMO Conference ' new technologies of manufacturing in the aerospace industry and space '

In the Centre of attention of the EMO Hannover 2013 are also new manufacturing technologies in the Aeronautics and space industry when the Institute for Machining Innovations Network for the town of Varel, in the North of Germany, and the technique of manufacture of machine-tools of the University Leibniz Hanover, Germany invited to participate in a joint two-day Conference. Already on 13, this prestigious International Conference will bring together specialists from the world of research and industry to participate in a symposium on current developments and future challenges. High level experts from all over the world that made use of this offer were very numerous in the EMO Hannover 2011.

- Special Exhibition ' innovations yesterday - today - tomorrow. Cost-effective solutions for processes with constructive components of quality '

For producers, economic solutions in manufacturing processes have a vital importance in relation to their ability to compete. Together with its associated companies, Machining Innovations Network shows, complementing the Conference EMO; ' New technologies of manufacturing in the aerospace industry and space ', to what extent are important comprehensive, innovative and close to practice solutions applied to high quality components. The peculiarity lies in the chronological exhibition of the innovation process. With an eye on the past, will show the jump that has occurred in the innovation in the field of the technique in relation to the current situation and how it will develop in the future. Thus, visitors to this special exhibition can be seen, on the one hand, solutions current that they can be implemented directly and, secondly, the huge leap that will produce in the future in the field of productivity.

- EMO India focus

India is one of the markets of growth in the machine tool industry. Already in the past five years the consumption of machine tools has only increased there almost by 25% to reach more than 2 billion euros in 2012. Currently, the country is in sixth place among large markets of machine tools. Equally important is the market which, as buyers, they represent sectors of the automotive industry and its auxiliary industry, the electrical and electronics industry and engineering industry in general, with a volume of imports of nearly 1.6 billion euros last year, offering good possibilities of business for international manufacturers of machine tools. In any case, also here there are special features for the business with companies in this country that must be taken into account in the export or the creation of societies. Against this backdrop, the VDW organizes the focus EMO India in which experts in the field report on the economic, political, legal and fiscal conditions in that country as well as special features that must be taken into account in relation to sales, services and structure of customers at EMO Hannover 2013.

- Enterprise Europe Network

The Enterprise Europe Network in Stuttgart, Germany, again organized a meeting of businessmen. Online platform provides partners appropriate for subjects defined in the run-up of the fair. These meetings are a very effective since the participants interests are mutual. So describe it in any case the participants in the meeting held in 2011. On that occasion, 156 experts from 25 countries carried out more than 500 talks organized by the Enterprise Europe Network. These entrepreneurs hoped to conclude numerous agreements of cooperation and orders as a result of the meetings.

- Initiative to attract new generations - technical machinery - a profession with great future

The machine tool industry will continue to need also in the future increasingly more qualified professionals if it wants to expand its innovation speed and its international importance. Taking into account the demographic evolution and further interests for technical professions, the German machine tool industry took years ago decided to create this initiative. In 2009, to motivate the new generations, created the VDW Foundation, under the motto ' machinery technician - a profession with great future ', invites, together with representatives of the industry, vocational training centres, universities and relevant government agencies for placement, more than 6.000 young people from general and vocational schools to participate in the EMO Hannover 2013. This initiative is an example of how the sector is confronted with the problem affecting many industrial and emerging countries throughout the world. Based on the famous motto of the EMO, 'Internationalism, innovation and great technique of production to the fingertips', wants to excite young people for technical professions in the sector of the construction of machinery. In the framework of an attractive parallel program, these young people will have chance to live live the exciting world of technology and machinery. The VDW Foundation offers guided tours through the exhibition to special groups of students. In this way, participants have opportunity to see how they work in the machines who are forming, ask questions and try for themselves. The objective of this project of the Foundation of the VDW and the exhibiting companies is to get new personnel for the sector.