Systems of measure for machines-tool of numerical control

The system of optimum measure for tasks of demanding positioning

The constantly increasing demand of the exigencias regarding precision and productivity in the construction of machines and plants, as well as the high standards of hygiene contained in national and international norms, require a continuous development of the systems of measure. In base to the focalización on his main activity, and to his philosophy of business oriented to the long term, Heidenhain is today, and also en el futuro, the correct partner for the success in front of the international competition.

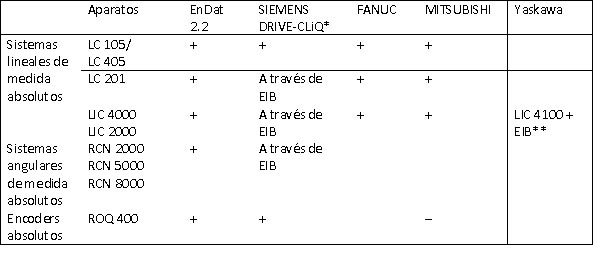

Shortly after the introduction of absolute linear measurement systems armored range LC 201 for machines up to 28 m travel, we now already extending it with new variants of important communication protocols. This is possible thanks to the adoption of these instruments by Fanuc and Mitsubishi.

Common to all variants of this range is the absolute graduation Metallur on a Ribbon of steel that once installed the different shells, mounted in a single piece. The next step - a length of measure up to 56 u 84 m - is now under development. This will allow replacement of the incremental version (382 LB), at the time available currently to 72 m. naturally, a system version multi-section measure always requires more time and effort of installing a system mono-seccion. For this reason expanded, some time ago the maximum length of the range measurement mono-seccion LC 100 to 4040 mm. Greater lengths than this would not have sense for mono-seccion version, since logistical problems that involve the manipulation of a rule of these dimensions would not be available for any of the parties.

Whereas in the LC 201 the development centred especially in the big length of measure and in a concept of simple setting, in the ranges LC 105/405 centred in the new protocols of communication and in the technician of hygiene. In particular, the versions with protocol for numerical controls Siemens wake up a strong interest. In January of 2013 the TÜV-Süd confirmed the aptitude of this group of devices for applications with Functional hygiene.

Although the new protocol of communication of Siemens (DRIVE-CLiQ) needs more electronic that, for example, the protocols EnDat2.2 or Fanuc, Heidenhain has attained to keep some identical dimensions for all the products. This simplifies notably the construction of the machines. This miniaturisation of the electrical components has been possible thanks to an ASIC typical of Heidenhain, developed in cooperation with the signature Siemens. This intense and narrow collaboration between Heidenhain and Siemens has showed his cost from does time, and his result is visible also in other groups of product.

In the last years, the tables giratorias accionadas with direct motors have happened to be a solution of niche to a standard. Decisive for this tendency are the highest dynamics and the absence of wear. Both characteristic are of particular importance in the mechanised of 5 axles, but also in machines of production. The combination of greater precision, resolution and speed of admissible twist do to the angular systems of measure RCN the systems of perfect measure for this application. On the contrary that in the conventional technician of accionamientos with encoders for the engine and an angular system of measure for the precision of the axis, with the technology of direct motors only has of an only system of measure for the hygiene of the machine. The protocols series are very advantageous an optimum dynamic, since the transmission of analog data bumps here with his limitations. The combination of an only system of measure, protocol of communication series and the new norms referents to technicians of hygiene require a certification of the systems of measure, for example, through the TÜV. This certification is in course and will be concluded to finals of this year 2013.

For the systems of measure of the range RCN is foreseen a certification by part of the TÜV-Süd for finals of 2013 like a system of only measure for applications related with the hygiene until SIL-2 (IN 61 508) or PL d (IN ISO 13 849).

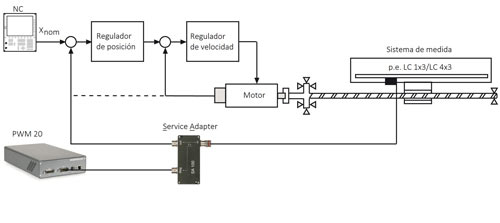

Diagram of the diagnostic.

As it is usual in all the systems of measure certified of Heidenhain, the mechanical exclusion of the error is guaranteeed if the setting is correct. There are two main reasons for the high competition of Heidenhain regarding the requests of the technician of hygiene of his systems of measure for machines-tool according to the new normative (IN 61 508 or IN ISO 13 849). On the one hand, of course, the development and the certification of his own protocol of communication (EnDat 2.2) and of the corresponding systems of measure. By another, the certification of the software and the hardware of the numerical controls Heidenhain and the resultant narrow cooperation between both divisions.

But are not only the requests of the technician of hygiene with protocols series those that force to new solutions. Also the diagnostic of the devices is subjected to fundamental changes. Whereas with analog protocols, as for example 1 Vpp, could listen ‘' during the operation and effect an on-line diagnostic, the corresponding devices with digital protocol (series) need to incorporate this intelligence in the device, ‘carry it on board' by like this say it. To the equal that before, in the protocol have to create and use the corresponding free zones.

The concept of numbers of evaluation, that describe the basic properties of a system of measure, simplifies the diagnostic of significant form. No longer it is necessary the expert knowledge that was used to to require for an evaluation of the analog signals, . Once entered this concept of successful form in the protocol EnDat, also has been possible to implement it for the systems of measure for Fanuc, Siemens and Mitsubishi.

With the device of adjust PWM 20 and the software ATS, Heidenhain is the only manufacturer of systems of measure that offers a tool of diagnostic for all the systems of measure Heidenhain with incremental and absolute protocols. This allows to verify the state of the systems of measure during the operation of the machine (on-line diagnostic) or during his setting or repair (off-line diagnostic).

Maximum precision for applications in the electronic industry

Beside the classical applications in the machine tool, the electronic industry has turned into the last years in an engine of innovation. This would not have to surprise if it considers the fast evolution of the size of the structures. This sector is predestinado to the success with the current priorización on quality and precision. The LIP 200 with protocol EnDat reaches a resolution of 31,25 pm. The limit of the reproducibility comes marked by the noise the electrical and is typically of 150 pm (RMS). In addition to these applications of the highest range, Heidenhain can cover also a wide spectrum of needs. Precisely the last development of systems of measure of strip, the LIC 2000, with an absolute catchment of only track, expands the range of product in the steering of ‘technician of measurement of basic level'. Although the requests of precision are, of course, less elevated that in the LIP 200, have not done commitments regarding the reliability. The size and the design of the fields of catchment, as well as the high automation of the production, guarantee the maximum of robustness and reservation of operation.

Principles of universal measurement in the technician of automation

The robustness is the steering of development for the encoders inductivos for servomotors and the encoders armoured. If possible conform with less precision/resolution, the technology inductiva can result attractor trucks for determinate applications that require greater robustness. The quality and the reliability of the encoders optical are very high, but in conditions extremely hard even they can reach his limit. This gap remains now covered by the technical inductiva. The newest range of product, the series ECI 1300, is indicated even for applications with SIL3. In systems of magnetic measure or inductivos without own threads, the distance of catchment and his variation during the operation is very important; in consequence, has entered in the diagnostic a number of evaluation, to end, such as it describes further up, to be able to evaluate it also during the operation (on-line diagnostic).

Dynamic efficiency

'Dynamic Efficiency', Heidenhain brings together a number of important functions of the TNC numerical controls for heavy machining. This simplifies the work of the operator of the machine, making at the same time the process of making faster, more stable and more predictable; in a nutshell, more efficient. Combines effective regulatory functions with innovative machining strategies, in order to increase the power of starting material and reduce machining time.

'Dynamic Efficiency' comprises the following three functions of the TNC:

- Adaptive Feed Control - AFC optimizes depending on the location of the machining progress

- Active Chatter Control - ACC reduces the tendency to chatter (vibration), allowing higher advances and greater depths of pass

- Trochoidal milling - accelerates rough grooves and cashiers

As is common in TNC numerical controls, functions are very simple and comfortable use for the user. The combination of these functions of the TNC, in particular, exploits the potential of the machine and tool, limiting at the same time the mechanical load. Its use is worthwhile. They are possible increases of the startup volume of material up to 20% to 25%, which translates into a machining weighed significantly more profitable.

HEIDENHAIN shall be at the EMO exhibition in Hall 25, stand D07.