Okuma (Machine Center) • Pavilion 27 - Stand C20

Okuma will present vertical, horizontal machining centers, lathes front and a new control

New family of control

Control integrates the system anti collision, which is planning the type of dish, piece and claws, with the CAD provided for this purpose, the machine equipped with this type of control is able to identify the possible collisions before they occurby stopping the machine automatically and giving a warning signal, indicating in graphic form, in that place and that way it would produce the collision. It is the only control on the market equipped with this feature.

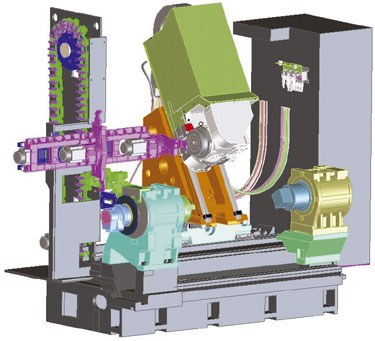

Okuma Multus B300

Presents a main spindle, with a capacity of turning and milling of 6,000 rpm, optionally 10,000 rpm. The standard cone is HSK63. It comes equipped with a storage of tools of 20 positions, expandable to 40 or 60. The B axis of 0.001 ° is also standard equipment

It is developed with the TFC (Thermo-Friendly Concept) technology allowing to ensure absolute precision under large temperature variations. The control is also the new OSP-P200, including assisted scheduling IGF-Advanced, next generation as well as the system anti-collision CAS (Collision Avoidance System).

Okuma LFG150

Fit to highlight the following points in the new family LFG150: its high rigidity and accuracy, is developed with the concept (TFC) Thermo Friendly Concept, which allows us to guarantee absolute precision under large temperature variations and requires short cycles of machining given his great speed of operation, as well as the high speed of the built-in charger. It is a compact machine, so allows a reduction of the space by 30 percent in comparison with the previous LFS family. In addition, it is equipped with the new OPS-200 control and requires minimum maintenance requirements.

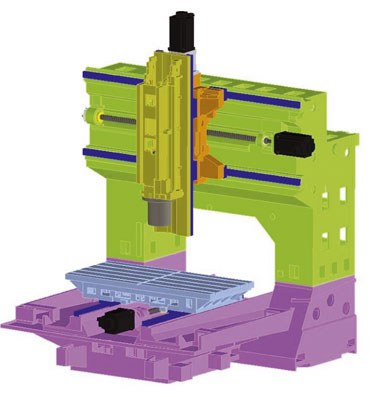

Okuma MB66VA

It has been developed with the technology (TFC) Thermo Friendly Concept, allowing to ensure absolute precision under large temperature variations, with large area of machining, a table of 1530 x 660 mm with a capacity of 1,500 Kgtours of 1500 X:, Y: 660-Z: 660, a spindle of 8,000 rpm, optionally 15,000, 20,000 to 25,000 (with BT40 cone). The standard is of 6,000 rpm, optionally 12,000 rpm to BT50. It has a breakthrough rapid 40 m/min x and and and 32 mt/min in Z. It has a weight of 11,800 kg, it is compact (17 per cent less space required) and a 20 tools ATC, expandable to 48.

Okuma MU400VA + 2APC