Innovative treatment of the blisk with a new process shot peening

Rolls Royce Germany has patented a new process of shot peening for the induction of residual tension of compressesion in the surface of the blisk assembled used in the aerial motors. The team of Rolls Royce together with the team of shot peening of Rösler have developed a system of shot peening that allows the entirely automatic measurement and precise of the components and the calibration of the filters of chorreado. A software of special calibration guarantees the total stability of the process of shot peening.

In the elements conventional compressesors for the turbines, the disk of turbine and the álabes are separate components, whereas in the case of the blisks, the álabes and the disk of the turbine are mechanised from an only piece (álabes integrated in the disk) of titanium or alloy of nickel and steel. In addition to saving costs by means of the elimination of the setting of the álabes in the disk, the utilisation of the blisks also reduces considerably the weight. However, the shot peening of these components poses some new technological challenges. For this reason, Rolls Royce Germany developed a new process of shot peening whose main characteristic are that the succión and lateral pressesure of each álabe individual are simultaneously chorreados with filters of special form. The distance between the filters of chorreado and the álabes is of only some millimetres. This small distance and the high number of álabes of the blisk, require a precise movement of the filters with a maximum deviation of 1/10 mm (around 0,004 – 0,010 inches).The precision required does that the calibración and manual measurement was very difficult and carry time, especially for the process of the blisk assembled, components that often consist in multiple blisks.

Absolute precision with a software of custom-made measurement

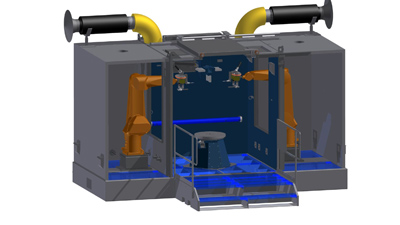

After an accurate analysis of all the ones of equipment of the competition, the customer chose the system of granallado totally automatic KU 40 of Rösler. A key factor for the decision of the customer was that the specialists of

The components to chorrear consist in different types of groups of blisks with variable quantities of álabes of the turbine and in different positions. After having placed the group of blisks in a special support, the operario ranges the setting and blocks them. Then the operario mounts the systems of measurement on the two robots and initiates the cycle of work. To end to attain an absolute precision and avoid collisions, the robots no only have to take the readings of the distance of the support of the piece of work and the real component, but it also has to range. For this purpose, mounted some special sensors in the inferior part of the table giratoria. Once that the three measures of the position of the component have defined exactly, the operario withdraws the measurement instruments of the robots.

The álabes are chorreados with the filters doing special movements, programmed individually. For this process of chorreado special, the pressesure of chorreado depends on the outlines of the shovels and, therefore, have to adjust individually. In addition to the measurement on line of the speed of chorreado, the continuous supervision and the adjust of all the pertinent parameters of the process, ensure that the value specified of tolerance Almen do not surpass . Besides, for each component treated, generates automatically a register of process in which all the parameters of the process are documented. The chorreado additional of the base of blisk llevar whereas the component is in continuous rotation.

The cleaning of the granalla and the system of recycling were designed and built in accordance with the existent aerospace standards and is instrumented with a separador in espiral and a system of tamizaje vibrant to separate the granalla unavailable. The continuous supply of the granalla to the filters of chorro is guaranteeed by a system granallado of double pressesure.

Programming OFF LINE of the new programs of granallado

At present store two programs of granallado in the PLC of the signpost of control of the system. For the treatment of additional components, the steps and parameters of process can be easily defined in some surroundings of programming on line with the help of a model 3D complete of the system granallado. The new programs can load directly in the PLC. The selection of the programs of granallado, the measurement and the operations of calibración, realise from the tactile signpost of easy handle.

Greater effectiveness in costs and a greater performance of the pieces

The automatic measurement of this type of components and the calibración of the filters of chorreado has translated in a significant reduction of the times of adjust. At the same time, the new system of granallado produces a considerably greater performance of the components. Another advantage is that the system of granallado KU 40 also can use for the reacondicionamiento and repair of the components used.

Like provider in every aspect, Rösler Gmbh is pioneering in the international market in the production of finishing of surfaces, blast cleaning machines, systems of painted and lines of conservation, as well as in technology of processes for the superficial finishing (deburring, decapado, desincrustado, polishing, polished…) of metals and other components. In addition to the German plants of Untermerzbach and Bad Staffelstein, the Group Rösler has branches in Great Britain, France, Italy, Low Countries, Belgium, Austria, Switzerland, Spain, Romania, Russia, China, India, Brazil, South Africa and USA