Efficient labeling with Powerlink

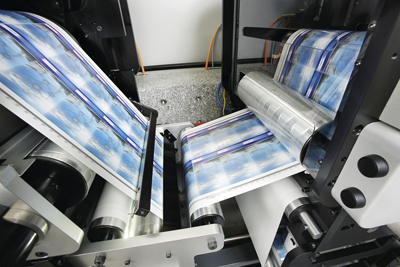

The lithography knows like the most ancient form of impressesion planográfica, and in the 19th century this method based in a stone allowed, for the first time, the production in mass of impressesions in colour. The manufacturer of machines Swiss printers Gallus uses again stones for the production of copies in colour. This time, nevertheless, in place to serve like sustrato of impressesion, the stone forms the base of the machine of impressesion of labels on line Gallus ECS 340, what guarantees an extraordinarily flowed process. The machine of impressesion of labels on line Gallus ECS 340 designed specifically for the production of commercial labels autoadhesivas: stickers created by means of the flexographic impressesion multicolor that attains excellent results without complex methods of finishing, like the tooling in hot or the sealed. The main application of these labels find it in the back of containers of shampoo or in the frontal part of basic products of feeding, cleaning and pharmaceutical articles.

“These segments characterise generally by the pressesure of the high costs, and the manufacturers see forced to work with margins very adjusted”, explains Stefan Heiniger, COO of the Department of Labels of the Group Gallus. “In spite of these restrictions, or rather owing to them, keep a competitive margin requires the high level of quality of impressesion and availability of the system that offer the devices Gallus. During the development of the ECS 340 follow the lemma ‘reduce to the maximum', with the aim to offer a solution for these especially sensitive applications to the costs”.

Costs of production extremely reduced

The break-even point between the quality of impressesion and the low operative costs achieves with the use of solutions vanguardistas, like the technology of servoaccionamiento ACOPOS of B&R.

“Gallus Has been the first manufacturer of printers of labels in entering a machine that uses of exclusive form the individual control of axles”, comments the director of department of Gallus. “The hard exigencias imposed on the machinery of impressesion of labels in the actuality only can fulfil with the servotecnología. These exigencias include short time of installation, set up fast of the machine after the change of product and minimum waste of material; all this with a quality of high impressesion and constant. The technology of servoaccionamiento of B&R fulfils to perfection with all these points”.

Used together with the system of communication in real time of high performance Powerlink, the technology of an alone axis based in servoaccionamientos of the series Acopos allows to configure quickly and adjust dynamically until twelve units of impressesion (ten units of injection more two units of perforación) in the Gallus ECS, taking into account the deviations of the process and reaching speeds of advance of until 160 metres by minute. This allows to change the type of labels and material quickly, produce proofs of impressesion in little time and apply a wide range of colours with total precision, avoiding like this errors of impressesion and waste of material. “For the companies of impressesion of labels, this represents a strong competitive advantage and a respectful activity with the environingingment”, explains Heiniger.

Total control of the costs of production

Owing to the fundamental paper that exert the accionamientos in all this process, Gallus llevar an exhaustive review of the possible providers in 2006, before initiating the development of the Gallus ECS. “The specification of design required an able provider to offer a platform of central control, as well as the accionamientos corresponding”, remarks Heiniger. “Keep the standard heights of quality, that define according to the tax of failures, was another fundamental requirement”.

This high level of quality plays a very important paper to the hour to keep basses the operative costs of the Gallus ECS 340. The managers of Gallus also saw of positive form the fact that the modules of double axis ACOPOS of B&R manufacture in series and that the accionamientos can install and withdraw easily during the process; a considerable advantage in a system of until 50 axles. The accionamientos configure automatically when they register in the controller and is not necessary to connect any computer of additional service neither install any software manually. Neither it is necessary reiniciar the system after changing an accionamiento. “These characteristics reduce the costs of process so much to the manufacturer of the machine, as to the owner of the same”, explains Heiniger.

Short time of inactividad by arrest of the machine

The capacity of regeneration of power of the accionamientos ACOPOS contributes to the owner of the machine additional savings on the operative costs. The width of the machine (11 metres with eight units of injection –until twelve possible–) does not suppose any problem for the solution of B&R, since the bus of CC can expand by means of modules of expansion. However, the capacity to regenerate the power of braked is not the most stood out point of the Gallus ECS. Still it is much more important the capacity, in case of break of band, failure of feeding or emergency, to use the kinetical power to place the machine in safe and clear-cut way, without the need of a source of external feeding, guaranteeing so the machine can reiniciarse quickly. In this case, the operario of the system benefits of the technology of integrated hygiene that provides B&R, that allows a fast connection, effective and logic to the standard controller.

The users also benefit of the fact that the servoaccionamientos ACOPOS use filters and modules of reactance to avoid consume reactive current, which avoids that the electrical companies demand units of compensation of additional power or load additional electrical costs.

Conclusions

The Gallus ECS 340 generates some minimum scraps and requires time of configuration very short with low operative costs, allowing like this an extremely profitable production of commercial labels of high quality. In sight of the numerous advantages that offers this innovative printer of labels, is not of extrañar that Gallus have distributed already more than 70 machines instrumented with the technology of high performance of B&R.