Escalabilidad Total even for the hybrid market

Synergies with the automation of machinery

Thanks to the integration of Automation Studio, a tool developed for the automation of machinery, in the system of control of processes APROL, the final users have to his disposal a wide fan of functions that exceed with grow the normal requirements of the automation of processes. By means of the utilisation of Automation Studio like supplement of APROL when it configures the hardware and the buses of field, the operario has access to a tool of engineering used by several tens of thousands of people to world-wide level. On the other hand, the automation of machinery every time requires more functionalities of system that provide continuity in the design, the gestión of the information and the maintenance, thing that does quite time that is a standard in the field of the automation of processes.

Topologies decentralised based in hardware X20

Thanks to his compact design, the utilisation of the system X20 like alternative to the classical system 2005 provides a greater level of granularidad in the islands of And/S remote. This comports enormous advantages in applications decentralised that allow a reduction of the total costs. Besides, like the bus of field Powerlink has the capacity to provide redundancy, can increase significantly the availability of the system in general. Also they integrate other buses of field such as Profibus DP, Modbus TCP or IO-Link that allow to connect systems or modules of And/S of third of reliable and easy form to configure.

Exist skilled modules for specific and innovative tasks, designed, installed and operated of the same way that any module of And/S X20. An example of them is the module of measurement of power and synchronisation of networks X20 (entrances for current of 5 To and for voltage of 400 V in less than 90 mm of width) that it is a solution of low cost to measure and recolectar data of energetic consumption and like this monitor the total energetic efficiency. Another example can be the module of analog entrances of 16 bits for signals of current and voltage with function of oscilloscope. With a time of sampling of 50 µs, the data capture and store in a buffer of the module that allows to house until 8.000 values. Can use a signal of trigger to start with and stop the capture, as well as to determine automatically the Min/Max of the values captured by the device. The content of the buffer also can save in a historical register in the controller for his back analysis.

The controllers use cards CompactFlash, of until 8 GB of capacity. This capacity of storage can use to register data of process, alarms and evento, including the instant in that they occurred, so that in the case that lost the communication with the team that registers the data, this information would not lose . Once reestablished the connection, the data stored in the buffer of emergency can transmit automatically to the historical archive.

Each controller has a server web integrated cheese cheese, in which the System Diagnostic Manager shows of form detailed all the notable information of the controller and of the modules of And/S connected. Also they can show custom-made contents, encouraged in function of variables of process by means of the utilisation of web pages based in SVG.

For the interaction on foot of machine, the Power Signpost are a solution of visualisation very attractor trucks and of low cost. The characteristics that provides the classical visualisation of Visual Components are totally integrated cheese cheese in APROL. If it wishes a solution of control for the electrical cupboard, then a Power Signpost can execute the part of visualisation, while the controller shares the values dynamically from the cupboard. In the case that wish implement a layer of control of emergency, then the application of visualisation can execute directly in the controller. This allows to operate from any computer authorised without any additional effort.

The technology of integrated cheese cheese hygiene improvement the efficiency ingenieril

Own supervision and of the system

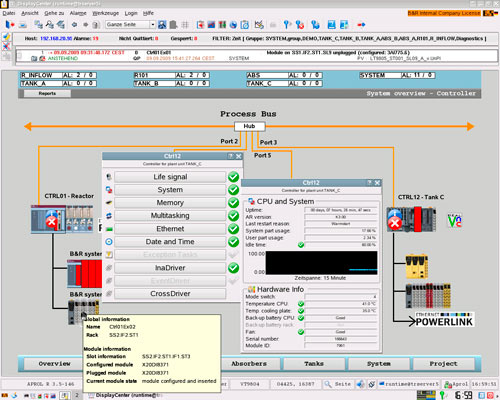

The supervision of the system and the one of the own system of control of processes are standard functionalities of the package APROL. In addition to the diagnostic based in web that offer the controllers, APROL collects all the information of the components of hardware used in the project, as for example stations of operator, runtime servers, engineering servers, stations of buses of field, etc. The operators can access to all this information doing an alone click with the mouse. For the notable information, the system generates and files automatically alarms and graphic of tendency without any additional configuration. The availability of resources, the functions of synchronisation and the performance of the system monitor constantly and show an alarm in necessary case.

Gestión of the information

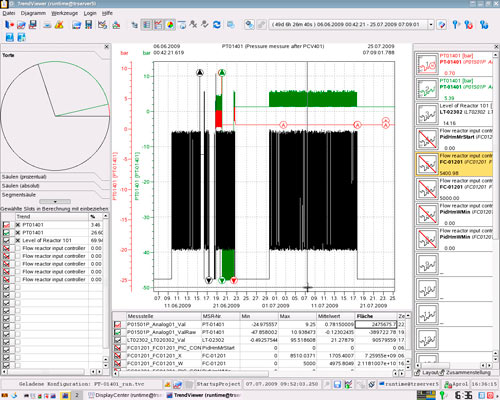

Thanks to the functions of analysis of the TrendViewer, the operarios can evaluate of efficient way the historical data without need to have special expert knowledges. The inclusion of all the alarms and evento registered by the system of control of processes, together with the options of representation that provides the TrendViewer, maximiza the quality of the analysis. To analyse the good and bad batches in relation to the quality of the product, can visualise simultaneously until 20 curves, specifying an offset of time for each one of them as well as the marks of start and end of batch, what allows to determine the “perfect batch”. Thanks to the crowd of additional functions like the AutoFit, AutoMove, AutoProcess, comments, rules and several options of visualisation of diagrams, the operario and the engineers of process have to his disposal a powerful and intuitive tool to show and relate the data of process filed. Besides, all this is possible without need to program, simply selecting the data wished by means of drag & drop. At present, the functions of analysis integrated cheese cheese allow to register and manage until 100.000 curves grouped in 5.000 groups.

Another effective form to represent data is by means of the form of reports. In addition to showing the alarms and the evento of classical form, also can realise reports of distribution of frequency. These allow to see cuán often occur alarms in a period of clear-cut time, if a concrete alarm produces , or which are the most frequent alarms, thing that results extremamente effective to analyse the crowd of alarms that do not cease to occur continuously in a lot of systems. Filter some areas of the system and points of measure while it analyses the list of frequency does simple to locate the causes of the alarms, what makes possible to solve them quickly.

Independently of the size of the project, the system of control of processes APROL always includes these functionalities, without need of any complement. This ensures that the systems always can operate of safe form, easy and efficient, independently of if there is 250 or 250.000 points of And/S.

The Integrated cheese cheese Safety Technology in the format known of the family X20 bears and simplifies considerably the tasks of engineering, ensuring a big efficiency in the process.

The functions of supervision of the system and of the own system of control of processes included in APROL allow an overview of all the components of software and of hardware at the same time that they register information detailed for his historical archive.

The integrated cheese cheese functions in the TrendViewer allow to evaluate the historical data of simple and efficient form without need to have special knowledges.

With the distributions of frequency and the powerful options of filtraje, can analyse the alarms and evento of intuitive form.