The materials composed en el futuro of the automotive sector

In the last years, the growth of the population has been proportional to the density of vehicles, in spite of the crises. And much more in the emergent countries. This does that the market grow to another side, out of the western countries. But far to be a problem, this means a new opportunity of developing investment and innovation for the western market.

For the automotive sector, these new circumstances suppose a change in the products in three big appearances: connectivity, efficiency in the resources and hygiene. These new shots join to the traditional exigencias of competitiveness, design and service by which always have governed us.

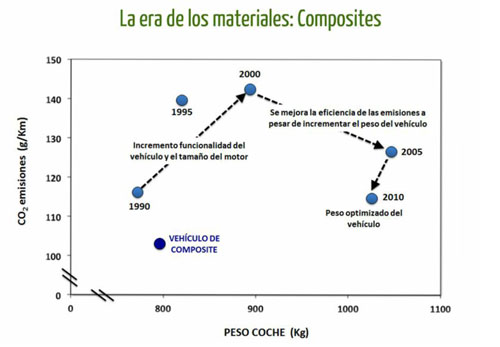

If we centre us in the efficiency, one of the solutions goes through the decrease of the consumption. But it can be something contradictory when the priority, to the hour to manufacture new vehicles, is to increase the power and reduce the sizes, already was in automotive sector, aeronautical sector component manufacturing sector component manufacturing or even nautics engineering. Thus, the way to the clearest answer does us think in the materials: how reduce the weight without the consistent loss of power. It is where goes in in scene the development of new materials composed like the fibre of carbon.

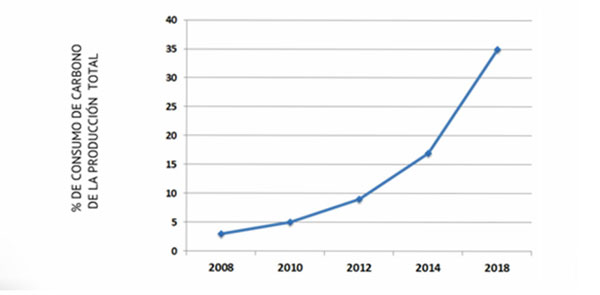

The fibre of carbon no only offers a reduction of mass of 4,5 times regarding the steel and 2 times the aluminium, but his efficiency resides also in the simplification of the productive processes and the needs of power related. Used beside the steel and to the aluminium, the composites, polymers and ceramic materials, can arrive to reduce the weight of an engine or a vehicle more than 50%. Of a piece of steel, 15% is material, the rest is the treatment and process until turning into it a functional piece (already was of car or aeroplane). However, in the compounds, the investment in machinery is lower in the order of 10 times. For example, if the piece is not in sight, does not need to be painted (since have high resistance to the oxidation and to the fatigue). East has been one of the main reasons of his big development in the aviation, happening of roughly of 15% in the ancient models to 60% in the new and that situates to Spain like leader of this technology to world-wide level.

The production of fibre of carbon in figures

In 2010, the world-wide production of compound materials approached shyly to 10 million metric tonnes and surpassed the 12 million dollars the past year. In the next years foresees a world-wide growth of Composites near to 6%.

But these advances no only are posed for the aviation. At present, They are llevar studies like Intercar (Intelligent Integration of carbon fiber in automotive) in United States. A project for automotive sector of the Spanish company Carbures, that supposes the rediseño of the support of the engine of the trucks for models of high range in fibre of carbon, manufacture of prototypes and the automation of the production. The result of the investigation will make possible to reduce the weight of the vehicles and with this his consumption and the broadcast of CO2 to the atmosphere. In the case of the electrical trucks will achieve visit a greater distance without recargar the battery.

Up to now, the fibre of carbon only comes using in the structure of the trucks in the first phases of the technical development, because of the technical and financial limitations that supposes.

Of the same way, could speak of ceramic materials to improve the efficiency of the motors in the behaviour to high temperatures. With the utilisation of ceramic mixed materials in motors of internal combustion, increases his efficiency, although his current cost and his development even today do them unfeasible (already use in turbines and turbocompressesors).

More about the fibre of carbon

The fibre of carbon includes in the group of the compound materials, formed from the union of two or more components, that give place to one new with properties and qualities very upper to the reached by each one of the components of individual way. In the case of the fibre of carbon, combines a fabric of threads of carbon (reinforcement), which contributes flexibility and resistance, with a thermostable resin (matrix), commonly of type epoxi, that solidifies thanks to an agent endurecedor and acts joining the fibres, protecting them and transferring the load by all the material; by his part the agent of cured help to convert the resin in a hard plastic.

hygiene, sustainability and efficiency in the manufacture

In addition to the advantages of weight and simplification of the process, to the moldear with fibre of carbon big units in an alone piece, are giving greater rigidity: they delete vibrations and therefore it increases the hygiene. In this appearance, the absorption of power of the fibre of carbon is 5 times more by kilogram that the steel, with what combining compound advanced with the pieces of steel can increase the hygiene of our vehicles.

In the ecological appearance, the recycling of the fibre of carbon, his recovery or the reuse of the same already is a fact. Without going more far also manufacture pieces of furniture or other applications with dust of carbon. Besides, It is advancing to giant steps in what to vegetal fibres refers .

Perhaps the greater part of the critical carry it to him the capacity of design. The steel has a very linear behaviour and is easier to calculate how can affect the strengths and torsions that in a compound, but the important barriers come given by the costs of the material, since it is a process of manufacture that does not allow to do pieces in big series. In this appearance, the cost of the prime matter will diminish when increasing the demand. Some first forecasts speak of the fourth part, that is to say some 7 upper times to the steel, that if we take into account that the costs of process can be of the half, would do the very competitive pieces.

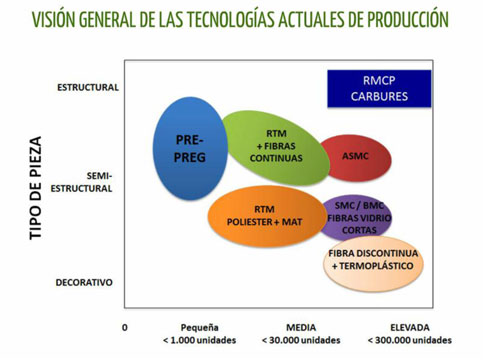

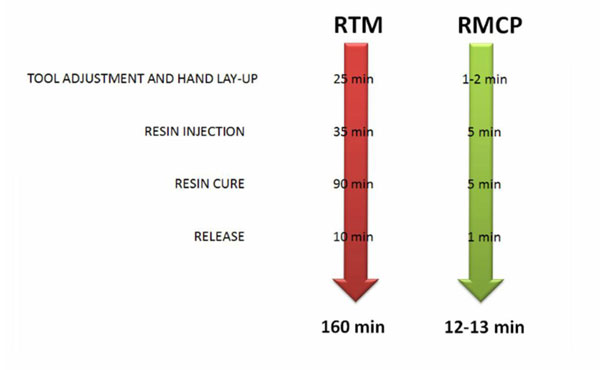

However, the future is hopeful in this appearance since, nowadays, works in processes called “out of autoclave” like the RTM, to achieve a continuous process of high volume. Like example of the future that comes, Carbures is working from does years in this line and has developed a patent on a process to do a piece each 15 minutes, what would make possible some 60 pieces/day in a first stage.

The world of the fibre of carbon (or better said in his amplitude, of the compounds with the multiple possibilities to incorporate them nanotubos or aluminiums) is a big opportunity. The technological advantage of our country in compound materials derived of the aviation allows to offer this technology to global and competitive providers of structures, the current Tier1, so that they offer and manufacture products advanced to follow leading this big world-wide market. This would not suppose, neither much less, the replacement of the metals by the composites, rather a convivencia looking for always the most optimum solution for each type of structure and bodywork. So much in vehicles as in aeroplanes, trains, etc... This combination will allow us be greener, safer and, of course, more competitive.

José Mª Tarragó is Engineer of Telecommunications by the Polytechnical University of Catalonia. It has worked in diverse consultancies until ‘landing' in Carbures Europe in January of 2012. Between them it stands out Ficosa, for which exerted of general director and later of vice-president during 18 years. Inside the aeronautical sector component manufacturing sector component manufacturing sector, Tarragó stands out by the diversification of the group Ficosa to synergistic sectors like the civil aviation and the military field with the negotiation and dimensioning of the project ALESTIS and the development of antennas fractales for the military sector American. His work saw materialised in diverse attainments in the distinct divisions of the company, creating common methodologies FDS (Ficosa Development System) and of production FMS. Equally it was the manager to develop the road-maps of evolution of his products and of the novelties that increased the value added to the customer.

Propellant of Joint ventures with technological companies like Fractus for the antennas of new generation fractales, with GMV for the development of boxes that endowed to the vehicle of communications and/or some intelligence. With the Japanese company Omron for the development of active systems of intelligent vision, has been the president of the consortium MARTA, project of four years of investigation on the intelligence in the vehicles and in the infrastructures to improve the hygiene.

Also worked like consultor and was member of the team that developed the bases for the reform of the Public function that gave foot to the law 30/1984 and collaborated with the company of strategy Mac Group in the new strategic plan of Fecsa for his integration in the energetic national plan.