Osseous implants of tantalum more competitive

Every time there are more people taken part in an operating theatre so that they implant them a fixation in the vertebral column. This support to the osseous regeneration attains to favour the fusion between the vertebrae after a fracture or a hernia discal. The implant, called box intersomática, is entered by the surgeon between the cervical or lumbar vertebrae. Said implants are pieces of metal biocompatible porous that facilitate that the osseous fabric invade them.

The producers of osseous implants has, then , an increasing demand and the challenge to improve the methods of obtaining of the materials biocompatibles to do them economically more competitive. To give answer to this need of innovation, in the Universitat Politècnica of Catalonia • BarcelonaTech (UPC) has developed a method that reduces the costs of manufacturing of the implants of porous tantalum. It treats of a process that have elaborated the researchers Kiara Riccardi, Elisa Rupérez and Javier Gil, of the Department of Science of the Materials and Metallurgical Engineering.

The porous systems of tantalum have capacities osteoinductivas, that is to say, stimulate the growth of the bone. With this metal obtain results that improve the ones of the traditional implants, elaborated with titanium. Another advantage of the tantalum are his mechanical properties: the structures of tantalum, that have between a 70 and 80% of porosidad, have a similar rigidity to the one of the porous bone. This property avoids that the loads accumulate on the implant and produce a decrease of the osseous density in these zones.

However, this metal has a high cost and the process to obtain the structures of the tantalum that commercialise at present is expensive and complicated. The creation of the structure with the usual method requires of a chemical tank of tantalum vaporised on a porous skeleton of carbon. This system, besides, supposes that they can appear empty spaces inside the porous system by implosion of the carbon.

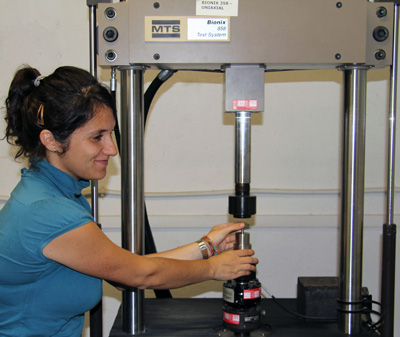

The innovation developed in the UPC, in the frame of the group of investigation Biomateriales, Biomecánica and Engineering of Fabrics (BIBITE) proposes a simpler alternative. “We mix dust of tantalum with particles of chloride of sodium, that compact in shape of cylinder. The particles of salt, responsible of the porosidad final of the implant, delete by dissolution in water and, by means of a thermal sensors treatment to 1.600 °C, sinteriza the porous structure”, explains Kiana Riccardi.

Porosidad Improved

To optimise the function of the implant is key that produce a good fixation of the bone. Precisely they elaborate systems with a degree of porosidad high, with a structure of similar interconnected pores to the one of the bone, because the osseous and vascular fabrics can grow in the interior. With the new method, attain structures with a porosidad between the 60 and 80%.

Besides, the measure and distribution of the pores is adjustable: “the particles of salt that enter have a distribution of measures predetermined, that establishes the measure of the pore and the degree of interconectividad that will appear once these delete ”, affirms Elisa Rupérez. In this way, it obtains a greater control on the diameter of the pores.

Although the biocompatibilidad of the structures of tantalum is widely known, have done proofs in vitro to verify that the new system do not enter any element that can be toxic and already have initiated in the process to patent this technology.

Index card of the investigation

- Who: Kiara Riccardi and Elisa Rupérez

- When: 2012

- What: Process to obtain porous tantalum

- Where: Upper Technical School of Industrial Engineering of Barcelona (ETSEIB)

- For who: Producers of osseous implants

- For what: Stimulate the osseous regeneration

Contact

Xavier Gil