Technology Aoki for technical containers of high value added

The technology Direct Heatcon of Aoki improves substantially the characteristics of the plastics, thanks to the pulled twinaxial (effect barrier and physical resistance) and achieves an only stability in the production of the containers, with repetitividad absolute of the characteristics and quality of these. Like the name of the own company suggests, Aoki Technical Laboratory is a laboratory that awards big importance to the investigation and the development of creative technologies, with a main aim, improve the modern world in which we live, prioritising save the environingingment.

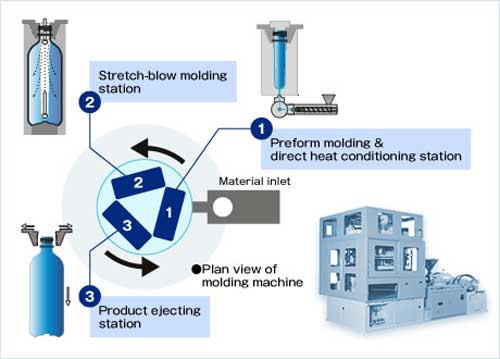

The system Direct Heatcom allows to manufacture containers of plastic blown, biorientados, splitting directly of virgin material in an alone machine. Combination in an alone machine Aoki Hybrid of two methods of moldeo different: injection and pulled-blown, to create a method of moldeo of containers that does not require of system of warming of preformas. Aoki Achieves to produce containers whose cost is inferior to the of a preforma injected.

In the same process of moldeo by injection of the preforma, conditions this térmicamente, which is decisive in the precision and high resistance of the products of fine wall, doing unnecessary the station of recalentado of the preforma. The residual heat distributed homogéneamente in all the mass of the preforma injected, allows that this pass directly to the station of pulled-blown, reducing drastically the energetic consumption, shortening the time of cycle, and minimising the need of refrigeration (repercussion in the investment in equipment smaller). And no only it is question of residual temperature, but the distribution of this, attained by means of the precise control of the pressesure and speed of injection, thicknesses of wall of the preforma, time of cooling and other parameters. After the injection, the preforma is moved quickly to the station of blown-pulled, where generates in final container, that later happens to the station of expulsion, totally finishing.

Different technical solutions incorporate for maximizar the efficiency of the machine, like the opening simultaneous movement of the top and inferior of the mould of injection, to shorten the time of cycle and, joining his hydraulics systems, reduce the necessary power of the bomb (lower consumption).

The table giratoria acted by means of servomotor that does more stable the cycle and minimises the consumption. Recycled of the air of blown that in place to be expelled to the atmosphere collects in a tank and reutiliza for other pneumatics movements, reducing the consumption of air compressesed until in 30%.

Productivity and saving of power

The technology of the machines Aoki prioritises the reduction of stages in the moldeo, reduction of power consumed and time of cycle, obtaining maximum quality and productivity. The wide experience in the most diverse sectors, allows to manufacture containers with an optimum precision in the neck with exact orientation of the thread, necks lighter that even can be blown partially with reduction of weight of until 3 grams by container and reduction of time of cycle of 3 to 5 seconds. In containers of wide mouth, Aoki allows to manufacture without ribs of reinforcement (smooth wall) to avoid the deformation, delivering of way adapted the material or bottles of oval profile in which it delivers the temperature in the walls of the preforma of determinate way so that the distribution of material and thickness of wall was optimum during the pulled-blown. Containers of neck descentrado with regard to the body, or containers of neck very narrow that remain very stable and perfectly homogéneos in the pulled-blown.

This technology does not limit to the most spread containers of PET for all type of carbonaceous beverages or no, foods, cosmetics, water or pharmaceutical but they are many the materials that can be employed depending of the sector or employment of these. For example the PC for low weight and high resistance to the temperature or PP with excellent barrier, estanquiedad and resistance and ligereza, for alimentary containers, doctors or cosmetics, PA, PES and PPSU for biberones, PMMA and ACE of clarity in containers of liquids or sauces, Tritán for menaje, HIPS for sour and alcaline foods, PE with high chemical resistance for dairy and other beverages, PET-G, PCTA and PCTG for cosmetics by his similar appearance to the glass, chemical resistance and of impact, COC and COP for chemicals and pharmaceutical, PEN with high barrier for the gas or PLA, biodegradable, and PET 100% recycled, that employs for containers for the chemical industry with a specific machine of Aoki that works with material 100 recycled from the trituración of containers of PET.

Almost 30 different models of machines of different sizes capacities and configurables for the diverse applications form the range of machines of pulled-blown of Aoki, signature that designs no only the machines, 100% manufactured in Japan with components and Japanese materials, but also the moulds, thanks to the high technological capacity of his plant of Nagano (Japan), one of the most advanced of the world in this sector.