Precision until the limits of the accuracy

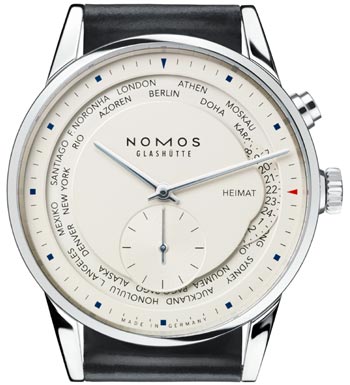

In the most oriental prolongation of the mountains Metalíferos, beside the Czech border, finds the German city of Glashütte, the ‘Mecca' German of the high watchmaking. Here it has gone perfecting this job along several generations. The signature Nomos Glashütte, carried by the own owners, manufactures from 20 years ago his own clocks in the location homónima and nowadays employs around 130 workers.

Nomos Glashütte Develops, designs and builds all mechanisms of the clock by own account. Depending of the calibrate, Nomos Glashütte also manufactures by his account until 95% of the loose pieces, mixing the high technologies with the manual work. Like this, the traditional solar reasons of Glashütte have been handmade until today. However, also they employ in this felt centres of milling with control CNC and a device of measurement of high technology of Zoller.

Loose pieces highly delicate

The mechanical clocks are complex and are composed of crowd of loose pieces highly delicate. The structural components, made in centres of milling, are like the map of construction of the mechanisms of the clock. The platen of the simplest model explains already of by yes with 63 levels. On these structural components rests and late the heart of the clock. In the own manufactura produces almost everything, was or no complicated. For this production use tools from a size of 0,29 millimetres. Those necessary special tools of until a size of 11,2 millimetres manufacture in the own company.

It demands a real precision

Only those tools that have been checked and controlled are guarantee of high quality. The most important requirement that demands him to the device of measurement is, therefore, the maximum precision to be able to reach the accuracy demanded for the manufacture of a mechanical clock. “We have gone in in a new dimension thanks to the device of universal measurement ‘smarTcheck' purchased does something less than a year” comments Frank Höhnel, tecnólogo of Nomos Glashütte. Until receiving the new device ‘smarTcheck' had worked with a manual device ‘smile' of 10 years of antiquity. However, this device no longer was adapted for the increase of the exigencias regarding rapidity and precision, as well as for the task of control of the entrance of commodities, since the device ‘smile' only covered the manufacturing of the tools for the machine. Of time in what, measured the tools by means of the laser in the machine. “However, here we found us with a significant deviation although the tool attached of equal way that during the processing”, says Dirk Wenzel, user in Nomos Glashütte.

Control of the quality already in the entrance of commodities

Also from the starting point of the extension of the mechanical manufacture, looked for a solution thanks to which could realise a control of entrance of commodities to the tools bought incidentally, as well as a measurement like the realised to the specific tools manufactured in the own company. An important appearance in this sense was the improvement of the quality of the tools used. The control already to the entrance of the commodities supposes the first stone for the aseguramiento of the quality since, only being the totally precise tools, also will reach the production of precise components. The precision demanded round the 4 µm.

hygiene of processes guaranteeed

The advantages of which benefits the company from the employment of the device of universal measurement ‘smarTcheck' are, especially, the saving of time, the reliability and the absence of failures, says Frank Höhnel. “The factor of human inhygiene finds excluded, the transmission of the data realises free of failures and no longer there is erratas numerical. The machines already have suffered some collapse because of this”, comments the user Dirk Wenzel. The hygiene of the processes is guaranteeed. The most important is the absolute cleaning and precision of the device of measurement by what, each two hours, takes place a calibración totally automatic of the device.

To the question of why have decided by Zoller, Frank Höhnel answers: “The main reason of this decision in favour of the device Zoller was the high precision”. Also they have played an important paper the good cooperation along several years as well as the fact that Zoller offer a service in situ by means of which realises regularly the maintenance and the calibración of the device of measurement. However, the argument that speaks more in favour of this cooperation is that Zoller realises the measurement in accordance with the current state of the technician. Greater precision is not possible. This last is what demands the manufacture of the clocks of high quality of the manufactura Nomos Glashütte.

Device of universal measurement ‘smarTcheck': comprobación and economic documentation of the tools

The device of universal measurement of high performance ‘smarTcheck' to measure to trasluz and with light incident is a true ‘all terrain' of the comprobación economic of tools before and after the sharp. With a simple ‘click' can control , measure and document the axial and radial geometry of each tool. The device ‘smarTcheck' is designed modularmente and can adapt to the individual requests of easy and economic way. So much with the manual version as with the version with control CNC, with the software ‘pilot 3.0' can realise the measurement of radii of cut, angles, long and diameters of form entirely automatic with so alone tighten a button. The optical systems of big resolution, in combination with the special lighting of Zoller, guarantee an excellent visualisation of the edges of cut by light incipiente. The device ‘smarTcheck' allows to realise comprobaciones fast in the control of quality of tools, as well as, in the way of adjust in the version CNC, the realisation of processes of measurement entirely automatic with automatic documentation of the control and preferably reproducible to discretion. Besides, it offers a big variety of functions for statistics and of documentation.