The high resistance, low density and excellent resistance to the corrosion do that the alloy of titanium was used in industries like the aerospace

A new approach in the mechanised of the alloys of titanium You6To the4V

Alloys of titanium

The alloys of titanium divide in three groups: α, α + β and β. We will centre us in the second group since the alloy You6To the4V belongs to this and is the one of greater use. His high resistance, low density and an excellent resistance to the corrosion do that this alloy was used in different industries like the aerospace, biomédica, chemical or military between others. Parts of the fuselaje are a clear example in the aerospace industry where is used by the previously mentioned characteristics although also it finds in parts of the turbine by his high resistance to the fluencia.

Is of great importance know to the hour to mechanise this alloy if this precipitated (aged) or solubilizada (annealed) since his behaviour is different and have to take into account some appearances that are determinantes. When we mechanise the material precipitated have to reduce the speed of cut in roughly 25% since his hardness differs of 41 HRc to 36 HRc regarding the material solubilizado. Also in the life of the tool sees reflected this difference reducing more or less in 30%.

Other characteristics that this material possesses, is his low thermal sensors conductivity and a module of elasticity relatively low. This first is the one who allows us that the heat produced in the process of cutting spread quickly remaining this in the tool. The high pressesures and the friction of the shavings on the tool generate big temperature on a specific zone accelerating the wear. For this reason our program Tinox has a geometry of cutting very achieved for the reduction of the efforts of cutting and a prompt evacuation of the heat with the shaving.

With a coefficient of elasticity so low, 54% minor to the of the steel, there is tendency to the deflexión during the process of mechanised. The piece tends to move away of the tool by the strengths of cutting what causes problems of deformation or precision in the piece. For this reason it is of great importance a development of subjection of piece the most rigid possible. More although of parts of the fuselaje treats , since in this section is where find us with the majority of pieces of thin walls.

A deficient subjection so much of the piece as of the tool of cut, will be so hurtful for the quality of the component as for the life of the tool. If the subjection of the piece is inappropriate will bring us dimensional problems and of quality of piece; if it does not have the sufficient rigidity to consequence of this surely will appear vibrations, added to the previously mentioned the premature wear of the tool. And by ultimo also would lose competitiveness since we will not be able to work in some parameters of optimum cut because the conditions adapted are not given.

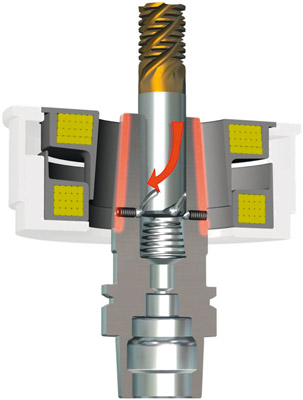

Regarding the subjection of the tool is important to stand out also that a good subjection; and I refer me to good subjection when has a concentricidad radial of 0,003 mm, strengths of tighten between 250 Nm to 350 Nm for a diameter of 12 mm, etc.; it do not have axial movements that ensure us a process of mechanised reliable. Emuge-Franken Offer Safe-Lock, a new system of subjection by thermal sensors induction more a helicoidal slot that ensures that there are not axial movements of the tool, or PWRGrip, a system of subjection by pinzas.

Parameters of cutting

In this section will speak on integral tools of hard metal. The speed of cut has a decisive importance on the wear of the tool. The factors that would have to take into account are: if we go to work in an operation of desbaste or one of finishing and which type of alloy You6To the4V will work and the characteristics of the tool (substrate and coating). Like general norm could say that for an alloy You6To the4V solubilizada the speed of cut for an operation of desbaste would be of 80 m/min whereas for an operation of finishing would mechanise to 120 m/min.

However to the hour to choose the advance by tooth have a greater field where move us and also have to take into account a lot of more external factors. Resumiendo Three parameters in one, would have to take into account: the thickness of shaving, that joins the advance by tooth (fz), the depth of radial cutting (toand) and the depth of axial cutting (top).

For example when increasing the depth of radial cutting (toand) increases the thickness of shaving generating a greater heat that transfers to the tool and increases the wear of the same.

A way to increase the axial depth (top) and diminish the radial depth (toand) would be working with a strategy trocoidal, which allows us take advantage of all the edge of an integral tool generating a good volume of shaving started (Q) and reduce the efforts of cutting considerably. This type of mechanised has improved a lot of in the last times since no only have created strategies the companies of CAD-CAM but also Emuge-Franken has evolved with them, developing in his program tools of 3xD and 4xD of length of cut with specific radii for the aeronautical sector component manufacturing sector component manufacturing industry.

And like last point to stand out of big importance is the refrigeration in the mechanised of this type of alloys. The percentage of fluid of cut has to be as minimum of 10%. A good pressesure of at least 40 bars reduces the temperature and evacúa with greater rapidity the shavings reducing the friction and doing safer the process of mechanised. Our tools have developed with inner refrigeration from diameter of 3 mm.