Interview Santiago Hernández Ariño, director attach of Sener Aerospace

In the first place, explain, between the sectors with that work in Sener, which percentage of the volume of business corresponds to the aeronautical sector component manufacturing sector component manufacturing. It can explain also how they divide the diverse activities of Sener?

Sener Has four general steerings that correspond to four businesses inside the aerospace sector: of the space, aeronautical sector component manufacturing sector component manufacturing, defence and of new technologies. Like this, the aeronautical sector component manufacturing sector component manufacturing properly comes to represent 15% roughly of the total volume of turnover of the aerospace market.

Is an important activity for Sener although it is not the only department that requires of machinery of high technology, for example to realise some mechanism of high precision for ‘space', although we are speaking of two or three units, where the importance is qualitative because we are in front of a technological challenge. They are cases in which the pieces to mechanise brush the border of the possible, so we need subcontractors that are reliable and that are still in us the development.

Equally, in the section of defence and aeronautical sector component manufacturing sector component manufacturing, in which we work with a lot of companies of mechanised, the reliability is again a very important factor put that they are products of ‘hi-tech', but also that they accompany us in the phase of development. It is necessary to take into account that they are projects that require of a lot of proofs and the phases of development affect to the mecanizadores and even to the manufacturers of the tools of mechanisation. In these cases, speak of short series, of hundreds or even thousands in some case.

Like this, to the subcontractor, ask him that it work with you from the beginning?

In the aerospace world the fundamental lines are reliability —one rests in the final quality of the product and if the chain breaks in some point can not fulfil with the exigencias of the customer— and the accompaniment in the process of development so that the subcontractor involve of active form. Later they go in to participate in the process industrial, that is after all where is the money. But to win the production in the majority of the cases it is necessary to have been the companion of the desarrollista main from the start.

To the hour to choose these subcontractors, which protocols follow?

Have a protocol of qualification of subcontractors so that, in essence, do an audits of his productive capacities, of his commercial reliability and of his financial resistance —would be a problem find us with a financial problem in the middle of a project although it also is truth that treat of soportales if they appear bad time—. In this process of election also demand a high technical quality. The projects realised in Sener are of high quality and requires of a ‘plus' of value added. Also we agree with them that follow our systems of inspection and control. By the contrary, do not demand them that they only work with us. We do not ask an agreement of exclusivity. We think that if have external customers, this does not influence negatively, on the contrary. That is to say, his final quality depends on that they have worked with other companies, the experience enriches them. In the case in that it can produce conflict, negotiate, because we neither can allow us that it delay the production.

In definite this posture answers to our philosophy of work. We do not have a vision cortoplazista but we treat to keep the relations with the companies with which work during long.

In the last years, this sector has won or stray terrain with regard to others for Sener?

Regarding design of aeronautical sector component manufacturing sector component manufacturing structures the true is that it can say that it has lost terrain, or as a lot kept in a similar level, since we are tied to the pure aeronautical sector component manufacturing sector component manufacturing sector, to the number of aeroplanes that manufacture . However, and it has been a grata surprise, are winning agreements of aeronautical sector component manufacturing sector component manufacturing tooling, what supposes some processes of different manufacture to the manufacture of pure pieces that also help to the industry of the mechanised.

How it explains the increase of these agreements?

In a lot of occasions the own designer of the piece is the one who better can define how has to be the useful to realise this piece. The true is that in this sector is complicated to define the pieces, toolings and organise the factory and the tools without knowing well the interiors of an aeroplane and his process of manufacture. And we are winning terrain in this section because we come of the section of the design and know well the sector and have a department of powerful engineering.

An experience that have attained seems that in few years. From when they work in this sector?

Is true that seems that have less path that other companies but has been because we have had a ‘Guadiana'. I explain me: we work in space, from 1967, in defence, to first of the years 80, in aeronautical sector component manufacturing sector component manufacturing, on the'84-'85. But the creation of IPT supposed the transfer of all the personnel to this new company, disassembling the internal units of Sener devoted to aeronautical sector component manufacturing sector component manufacturing engine, etc. Afterwards reconstructed this department, leaving the section of engine in ITP, recovering subjects of defence in the world of the missile, where participates a lot mechanised, and capacity of metallic design and in fibre for the world of the aeronautical sector component manufacturing sector component manufacturing. Of some way can say that the creation of ITP explains the ‘disappearance' of Sener in this sector during a time. The new aeronautical sector component manufacturing sector component manufacturing stage answers to the last 10-12 years roughly although, from a technological punto, in Sener treat the four markets like a unit conceptually so that the ‘small brother', the aeronautical sector component manufacturing sector component manufacturing, is backed by the others three.

If we speak of the ‘core business' of Sener, of what would be speaking specifically?

It could stand out any of the current tendencies in the manufacture of aeroplanes that affect to the activity of Sener?

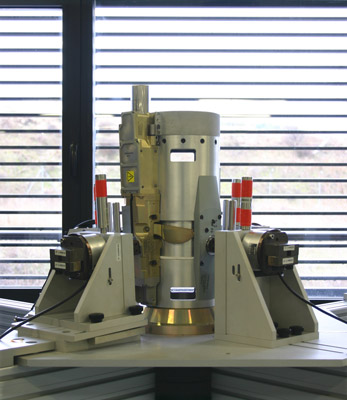

The aeronautical sector component manufacturing sector component manufacturing world is progressing to the efficiency through several improvements. All that that does not spend in fuel revierte in a better economic efficiency and environingingmental, is evident. How attain it? Increasing in what it was possible the efficiency in the design of the aeroplane and lightening his weight. All the modern systems are oriented to attain this aim and the introduction of the fibre goes in this line, treat to reduce the weight of the aircraft. And it will continue being a tendency because it is the future. It exists another factor that goes in at stake, and is the noise, that requires of a big quantity of power to create , what translates in consumption of queroseno. Like this, do the greenest ‘aeroplane' means a lower consumption. And although it is true that it is necessary to do an investment in the long run improves the cycle. Like this, from the punto of design, it is necessary to tend to aeroplanes lighter, more resistant, more final, and from the punto of manufacture, it is necessary to opt by automatic systems that improve the efficiency and therefore the quality. In Sener have developed a machine of special design for Airbus, installed in Illescas and in Germany, that realises the larguerillos of the aeroplane and his coating of fibre. A machine of the measure of a wing to do a tooling. But to be able to do this work it is necessary to know how is the design. In Sener our work bases in conceiving the machine and our network of mecanizadores helps us to develop it, that afterwards will sell like a key in hand, because we hold us responsible to sell it like an all, something very important for the customer.

And the aim is the reduction of the consumption of fuel, something in what the design plays obviously a very important paper, and where uses all type of material, no only fibre of carbon: alloys more sophisticated or combinations of alloys with fibre…

Like this, seen from the optics of the owner of a workshop of mechanised that it will have to give service to all this technological evolution, have to prepared for processes that will be more complex but that will give better performances. And it is necessary to arm in procedures that give us guarantees that the result is good.

In this context, thinks that the industry current subcontractor adapts well to the specific needs of this sector? It is very instrumented to realise pieces for the aeronautical sector component manufacturing sector component manufacturing?

There is of everything. Some himself have done a true effort but to others will cost them more. In Sener do not ask that our subcontractors, for example, mount a department of international right to attain agreements went. This can do it we. But yes we demand him that it was prepared to work with compound materials and with projects complicated. It is a really global market and very competitive. It does not treat only to be well in the work but also to follow protocols and determinate procedures. And this is very complicated without investment. Therefore we speak of the accompaniment in a long cycle.

Often the problem of the Spanish auxiliary industry is the dimension. That is to say, the SMEs possibly do not dare a lot of times to realise important investments to be supplying of companies like Sener. On the other hand, they do not see prepared to assume the risk of the mechanised of pieces, for example, of materials very costly. They find in Sener with this problematic?

The true is that it is very complicated to go out to the market without a plan of investments. It is very difficult to live on a national scale and the leading companies that are going out forward are those that work to attain agreements on an international scale and, in the majority of the cases, in collaboration to half long term with a company of elder visited as it can be Sener, that commissions of the design. That is our diagram of work and can say that it has resulted us.

In which projects work at present?

Are immersed in some projects but are confidential. We work with a Russian company, doing offers in Brazil, also in Middle East… but can not desvelar more.

Already realised stand out the machines for the larguerillos installed in Illescas and in Germany.

It can explain which part of these projects llevar them Sener with his own capacities and which subcontracts?

Subcontract enough. We reserve us the paper of designers of the system and the hardware so that, except some very skilled development, subcontract until a 70-80% of the cost of the project. In general, we commission us of the design, the final integration and the sale key in hand.

Ours internal production reserves to prototypes or questions very very concrete, so it can say that we are a big subcontratador.

What would stand out of the technology of Airbus and his standards of quality?

Have some good standards, very accepted. But it is necessary to take into account that they are standard dynamic. After all, the standard is the experience purchased reflected in a paper, so after each project it is necessary to do an analysis and review of the same. Therefore constantly they appear new standards. And so that this work, no only has to be of quality but besides it was admitted. It is not question of law, because it is necessary to differentiate a certification in base to criteria of hygiene, etc., of a standard of procedure of manufacture of a company. The standards have to be a put in common and accepted by the majority, and here also plays a fundamental paper the technology. Some companies can not follow the standard and remain ‘descolgadas'. And that is one of the problems of our SMEs, reach the technical cruising speed.

According to his knowledge of the sector of the mecanizadores, in what thinks that has to improve this Spanish industry?

For example in the acceptance of the standard like pattern of measure further of the personal voluntarism. That is to say, to do a prototype, possibly can do of way artesanal. But it is not possible for a series, that governs in terms of average. And the standard has to see no how a cost more but like a saving on a long-term basis. Yes, they are more papers but improve the efficiency of production. It is necessary to take into account that a game of pieces badly done paralyses the production of something that can cost 100 or 1.000 times more. The effect devastador of an error in any detail paralyses all the process. The effect multiplicador of something bad fact is terrible, with the consequence that they ensure that they do not go back to work with them.

It is necessary to understand also that in the chain of production all the links are balanced. It can not be that ones ‘throw' a lot of and others remain left behind. It is necessary to work like a convoy, that goes to the step of the slowest. Also it is necessary to improve the internal organisation of the companies. It is fundamental to fulfil with the terms to which have engaged and be to the day of the technological novelties.

By all this is fundamental the reliability. The main contractor needs to trust his subcontractors.

In definite are subjects of common sense, like the control of internal costs. Analyse in all the chain of production where are his savings, which is his minimum size of company, the optimum size, etc. and evaluate it permanently, that form part of the procedure.

Also is true that many small companies realise an effort of investment to purchase a machine 'hi-tech' but that, however, follow working as 30 years ago. It is necessary to know the procedures of these machines that will allow them improve his production and, to his time, change some ways to work to improve and be more efficient.

However, we see a lot of Spanish companies in European projects…

True, and from our experience, has to , among others factors to that when accompanying us in international projects the companies have given to know, what has allowed them penetrate in this market. Like this, before arriving the crisis, some of them already had sufficient name so that companies extracted called them to work with them. And this has been thank you, partly, to that companies contractors like Sener put them in the ‘diary'. It is necessary to take into account that in Europe ask references: they want to know in what have worked previously, so have projects already realised with companies like Sener in his have is a guarantee. Of another way, is very complicated to compete in the market, still with good prices.

Which is his degree of competitiveness?

Is good. I think that the foreigners discover true jewels. The problem in a lot of occasions is not so much know do but show that they know it do. Give to know is basic and have a previous experience. Have worked for Airbus gives the guarantee to any another contractor that you have all the requirements to fulfil his procedures. Without this, is very complicated that they sue them. And the companies of mechanised Spanish have to think that his natural market is Europe, no longer is Spain. It is very important that understand it. And for this is indispensable to learn English, because all this demands it the market to the that want to orient. Also be well in his work, because there is a lot of competition and each company contractor opts by companies that already knows, so it is necessary not giving reasons to these companies so that the descarten.