B&R Automates entirely his new logistical centre

The new logistical centre occupies a surface of 6.600 square metres and the shelves have a height of more than 19 metres and a length of 72 metres, housing a total capacity of 18.000 palés.

Logistics automated with technology B&R

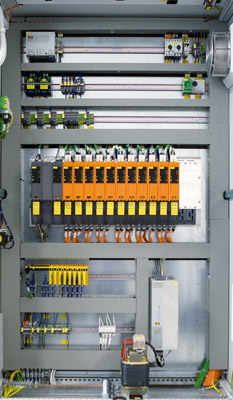

A total of five vehicles transelevadores of paletizado collect and deposit the material in shelves of two sides with enormous precision and an entirely automatic gestión. With a total of until 150 double actions to the hour, achieve extract or store until 300 palés to the hour. The vehicles transelevadores are coordinated by eight stations of gestión that direct all the operations of the warehouse. The systems of automation and of Entrance/Gone out of the series X20 of B&R commission to achieve the greater possible performance of this installation of last generation, but at the same time of remarkable complexity. On the other hand it has set up all a system of technology of hygiene managed by the SafeLOGIC of X20 and with an architecture of SafeIO, decentralised in POWERLINKsafety, and also pertaining to the family of X20.

Like visualisation, the operators use the Automation Panels of B&R, that allow a handle intuitive and simple of the complete warehouse, or of determinate specific zones of the installation. Besides, they exist some mechanisms of maintenance and remote supervision that allow to know from the generic state of operation of the warehouse until the value of any one of the entrances or exits that there is in the installation. Besides this information also is available to be sent by other means like a simple SMS or an ecouriers.

The highest level of precision with the best energetic efficiency

All the servoaccionamientos of the warehouse are instrumented with technology of servoaccionamientos of B&R. The installation is prepared to transport until 72 metres and situate with big precision europalés of until 1.000 kilos of weight, reaching in these processes accelerations in the order of the 2,5 m/s². The capacity of energetic regeneration that have the ACOPOSmulti allows to reduce the energetic consumption in 30%.

Direct connection between the SAP and the automatons

SAP R/3 THEM (Logistic Execution System) uses to manage the stock and control the flow of materials. The automatons of the warehouse are directly connected to the module of SAP R/3 TRM (Task and Resource), saving in this way the computer that manages the flow of material. Neither they are necessary the databases that contain the state of the storage and that involve a high cost of maintenance. SAP R/3 commissions to schedule the order in which they execute all the operations that have to llevar, as well as of the strategies of recovery of material.

The movements of stock process through SAP in several Automation PC of B&R that find installed in the own warehouse, whereas the internal transport controls and verifies by means of the use of mobile equipment of acquisition of data, what guarantees that the location of each one of the products was known at all times.

Integrate the technology B&R in systems of storage allows to attain economic logistical solutions and of a big efficiency.