Interview to Carles Jiménez, commercial director for Catalonia of Maquinser

In

Perhaps first we would have to establish what is a machine multifunción for Maquinser and what is not it…

A machine multifunción is that that combines different technologies. What understand basically by a machine of turning that can mill and even rectify. In essence they exist two big groups: the lathes that mill, more usual, and the milling machines that tornean. Always under the principle to avoid different tie up of pieces, that is to say, realise the possible maximum with an only attacked. Afterwards already we would speak of combinations: they are machines multiejes with a cabezal giratorio, that can be bent, with continuous twist, etc.

The machine multitarea standard, however, is a lathe with a cabezal of centre of mechanised, orientable. The variations affect to the dimensions, the length, the capacities of tools, possibilities of the cabezal, etc.

Which are the functionalities that now sues the market? They ask special developments?

Exist two big segments. Have the piece of turning that requires milling, work for which developed the machine multitarea, speaking always of milling external. The problem is that these machines, with the type of cabezal that incorporate, are not adapted for milling inner of big diameter. For these works have developed machines like the Cublex.

Is a centre of mechanised of 5 axles, that offers a lot of more possibilities: mechanised with 5 more milling axles but with another advantage as it is can tornear in vertical or in horizontal. It supposes a more precise work, with lower manipulation of the piece and reduction of the time of work. Because at the end the industry evolves to machines neglected. What less attention continued of the operario need , more profitable is the production. This will be able to occupy of the control of quality or to prepare the following piece, for example.

Another variant more is that they also offer the possibility to rectify. According to the model can devote to realise axles longer or to develop what designate the dish, without too much length. But in any case, and in spite of that the machines incorporate already a software of programming assisted, is indispensable to work with powerful systems of design CAD-CAM. And it is that precisely, since these machines realise so many tasks, exists the risk of collisions. We are speaking of pieces of high value, so any chequeo by anticipated, better.

This type of machines admits until 520 tools, in system matrix, with crowd of palés.

To which segment or sector is more focused this type of machine? Which is the one who now is better positioned to purchase them?

With which more work we right now is the segment of manufacture of tools properly. It is a sector in which it has produced an evolution. Up to now they combined a lathe multitarea more a unit of rectified back, and even in occasions a machine of 5 axles, but the processes change. In the actuality pretends work with materials toughened, reducing the manipulation of the piece. Thus it is interesting to incorporate the works of rectified in the own machine. It fits to stand out that we are speaking of special tools, no of massive production. Broaches To mechanise 3 or 4 diameters simultaneously, for example, or tools combined, etc. All that no standard.

Obviously also have a very interesting application in the world of the aeronautical sector component manufacturing sector component manufacturing. This sector is leaving to use the aluminium and opts by the important pieces of materials of high durability like titanium or his alloys, whereas the majority of the others parts are manufactured in fibre of carbon, for the reduction of weight and, in consequence, of the consumption of fuel. For example, in the new project of the To350 that develops in Illescas (Toledo), the wing of the aeroplane measures 35 metres but weighs a third part that the previous because it is realised entirely in fibre of carbon.

Also exists another very important market in which we are having an important penetration, with a lot of demand: the mechanisation of complex valves, already are for gas, water, etc. What understand by conventional valve, usually requires of a mechanised inner. With two or three mouths situated to 90º, these pieces can leave smart, with this type of machines, in an alone attacked, what improves considerably the speed of production.

Until which point are modulables these machines?

Say that it splits of a basic machine to which can him incorporate, according to the needs, systems of gestión of palés, of gestión of tools, chequeo of break of tools, system of measurement, identifiers of tools by chip, etc. In the Cublex-63, for example, the standard are 2 palés and 51 tools. From here, until 520 tools.

We are not speaking of conventional machines. The Spanish companies are in conditions to purchase this technology?

It is necessary to say that the offer neither is conventional. If we speak of a lathe with cabezal fresador like the Smart Turn of Biglia, would dare me to say that almost any manufacturer recognised of the world has in his catalogue a machine of this type. But the complex technology Cublex is in hands of very few manufacturers. Regarding the companies, exists less demand and are operations very concrete. But in Spain yes there are companies that have some model, especially in the aeronautical sector component manufacturing sector component manufacturing sector. Also in the manufacture of special tools, whereas in the one of the valvulería, there is less implantation, although yes there is some company that has a machine of this type.

In front of the possibility to develop a project, for which the company requires a concrete machine, sue them financials?

Yes, and is that the fault of financials is the big problem of the industry. And no only already to buy machines, simply for the day in day out. But also I have to say that our experience with the Bank Sabadell and the agreement with the ICF (Institut Català of Financialss) has been very positive. Also we work a lot with Pimec and his advice supposes a big support to throw advance projects of customers. However, any one of these credits, already was of European field, the ICO or the ICF, require a lot of bureaucracy, what brakes a lot of projects put that anybody realises a request without knowing if it will have the credit to purchase the machine.

But no everything is negative. Catalonia has increased his exports with a basically related data with the industry of all type, and that is a data that says us that the big majority looks to outside. As many of our customers, that follow working, although basically for the outside.

To finalise, could stand out some operation of machine multifunción recent?

One of the most recent projects have realised it for a company that mechanises pumps for the sector of the water. A request for a machine multitarea with 80 palés and 520 tools. Another project, slope to deliver, is for Iscar Iberian, for the manufacture of tools. And for the aeronautical sector component manufacturing sector component manufacturing sector deliver a Cublex-63 for tools of titanium, that already is operative.

Japanese Manufacture 100%

“Matsuura does not manufacture at all out of his two factories of Japan. Not even the streamlining, what partly is a problem. A lot of of the competition of Matsuura has relocated his plants of production, being able to like this reduce his costs of manufacture and leaving to Matsuura in the highest part of the scale of prices. This allows us compete in the segment of the high technology with machines like the Cublex. But to attend the miscellaneous demand of the market, in Maquinser distribute a lot of other signatures and even also commercialise European machinery, diversifying like this his offer and covering all the range of machines”.

Cublex-63, ‘a new was in machines multitarea'

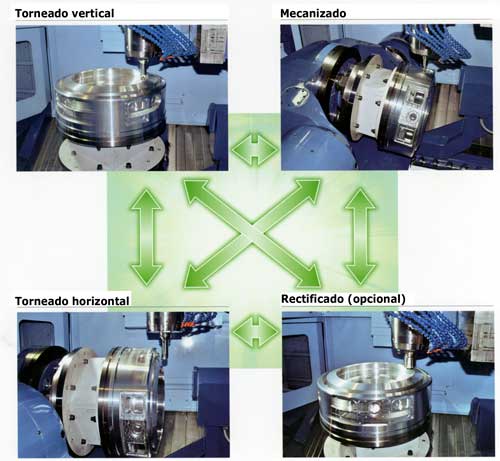

The Matsuura Cublex-63 is a machine multitarea developed to fulfil with the high exigencias of the current market such as: reduction of costs, pieces of greater value added, high precision, operations automated without human presence. It consists in a centre of mechanised of 5 axles combined with the option of turning so much in vertical as in horizontal and where the axis C can reach the 1.300 rpm. The machine can incorporate also the option of rectified.

The final result is a machine máscompacta that the traditional machines multitarea, with greater capacity of milling, adapted in turning and that offers the versatilidad to endow the change of pallet standard of different solutions mulitpalé and capacity until 520 tools modulable. The option multipalé is fundamental to be able to have different placed manufacturings in machine offering greater possibilities of flexible production in small series demanded in the competitive current market. It obtains besides a remarkable increase of production to the not having need to stop the machine to realise new manufacturings.

The Cublex-63 allows to mechanise a piece of 630 mm of diameter by 450 mm of height and with a maximum weight of 450 kg, on a palé of 500 mm of diameter. The machine reaches precisions very elevated in circularidad milling (1,94 micras) and torneando (1,35 micras), being the cylindrical precision of 1,24 micras in 300 mm of length.

Incorporates in his standard endowment of the new system thermal sensors sensors Meister of thermal sensors compensation, Handy Mann II for maintenance and fast set-up and function of chequeo of a correct balanced of the piece.