Máquina Center, S.A. (MAQCENTER) - CNC numeric controls

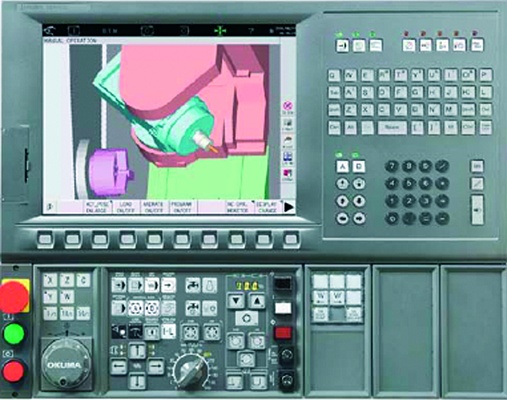

Okuma OSP-P200

Numerical control: with functionality based in PC fully integrated cheese cheese

The numerical control OSP-P200 of Okuma has a functionality based in PC fully integrated cheese cheese. The PC-CNC designated Okuma OSP-P200 works with two operating systems independently, one for the function of PC oriented to the operator and another for the operation of CNC. The mutual platform is a compact support of CPU, integrated cheese cheese in the cupboard of control, with processor Intel Pentium M, hard disk adapted to the industry, main storage DRAM in addition to a supply of hygiene in case of interruptions of electrical supply.

Like software, uses the operating system Windows XP oriented to the user and the reliable parallel operating system additional and independent of CNC in real time for functions of the machine.

It incorporates interfaces of PC more widespread and the control comes instrumented with two ports USB. It integrates the new protection against collisions CAS. With her, the users reduce the time of proofs of the new programs NC until a 50 %. CAS No only simulates the situation of mechanised virtual before the production, also makes possible the comprobación in real time during the mechanised of the first piece.

To show the data and charts, the Okuma P200 uses a LCD of 15” with resolution XGA (1.024 x 768 píxels) with tactile screen. Like this, can work with ‘finger in the screen' or pencil PDA and with the mouse via USB.

The PC-CNC offers a control that allows to activate an alone use no restricted to the programs of the low PC Windows XP, together with the operating system CNC independent and without failures. With the help of the innovative system to avoid collisions CAS, especially the users of machines multieje reduce the times of manufacturing and proofs.

Like software, uses the operating system Windows XP oriented to the user and the reliable parallel operating system additional and independent of CNC in real time for functions of the machine.

It incorporates interfaces of PC more widespread and the control comes instrumented with two ports USB. It integrates the new protection against collisions CAS. With her, the users reduce the time of proofs of the new programs NC until a 50 %. CAS No only simulates the situation of mechanised virtual before the production, also makes possible the comprobación in real time during the mechanised of the first piece.

To show the data and charts, the Okuma P200 uses a LCD of 15” with resolution XGA (1.024 x 768 píxels) with tactile screen. Like this, can work with ‘finger in the screen' or pencil PDA and with the mouse via USB.

The PC-CNC offers a control that allows to activate an alone use no restricted to the programs of the low PC Windows XP, together with the operating system CNC independent and without failures. With the help of the innovative system to avoid collisions CAS, especially the users of machines multieje reduce the times of manufacturing and proofs.